Rubber belting plays a very vital role in several factories and industries. It is applied in various ways to improve the performance of machines and to speed up product development. Shandong Xiangtong Rubber Science is a manufacturer that specializes in creating high-quality rubber belt conveyor specification. They provide durable and versatile rubber belting.

Rubber belting is present in all sorts of factories. It does wonders in machines that produce essential products such as metal, plastic, and paper. Rubber belting, for instance, is what moves the paper materials around in other areas of the factory when a factory produces paper. Rubber belting is also utilized in conveyor belts, which are long belts designed for the transportation of materials over long distances. This is very helpful because it consumes less time and makes the work simpler. Even a bakeries use rubber belting! They use it to assist in moving cupcakes, cookies and other bakery items along a production line. This explains why you never know where you will find rubber belting!

Rubber belting is used to make factories run more efficiently and quickly. The rubber cleated conveyor belt makes it easy and fast for machines to transfer products from one machine to another. This allows factories to make more in a shorter time. For example, assume a factory produces 100 items per hour using standard belts. With this they can produce 400 products per hour if they change to rubber belts! So factories can handle very high demands and send more products to customers faster.

Factories will be changed due to use of rubber belting. It allows them to operate at a very high-speed and enables them to create more products at a shorter time. By being able to make more the factories can sell more items, thus garner more sales. It also means they can reach more customers with their products.” Rubber belting also gives factories greater safety. First and foremost, factories can increase the safety of moving materials with rubber belting. In factory environments, safety plays an indispensable role.

Reasons to Consider Rubber Belting for Manufacturing Phased Rubber Belt: Rubber belting is score solid and has a long assistance life. So it can withstand a lot of wear and tear, making it perfect for the busy surroundings of factories Second, rubber belting is pliable, and so its uses are numerous. This enables factories to use cleanup production lines designed specifically for their circumstances in order to optimize effectiveness.

Finally, rubber belting is simple to maintain. Also, if a belt breaks or needs changing, it can be quickly and easily replaced without causing any interruption in the production line. This rapid maintenance is crucial as it saves the factories both time and money. This makes each factory a far more economical solution if it can keep running smoothly.

This is just one reason rubber belting is used in so many different industries, as it can work in a number of different applications. It can transport materials from machine to machine, assist in development of production lines or even serve as part of a safety system. Rubber belting is helpful in so many things, you'll see it in everywhere, from manufacturing to farming!

ISO9001, ISO14001 and ISO45001 are the three rigorous standards that we have been able to pass. Our products have also rubber belting successfully passed the quality tests conducted by renowned organizations such as RWE, TUV, BV, MSHA and MASC.

Our rubber belting team is comprised of experts responsible for setting national standards. And we have obtained 32 utility model patents for national use for example "multi-ply textile conveyor belt" and has issued 3 invention patents, and 11 utility model patents such as ultra-wear-resistant conveyor belts and has partnered with a variety of universities, which shows the company's leading position in rubber industry technology. We also have an huge and efficient after-service staff consisting of 32 people.

The company boasts modern production equipment, professional management team, and top technology, so that the company has developed into a formidable competitive ability of the enterprise and the PVG conveyer belt holds the highest percentage of the rubber belting in China. We are vice-chairman in China's conveyor belt market and also one of the leading makers. The company was awarded the honor of "China Quality brand" and "The most important brand in the area of conveyor belt in China", etc.

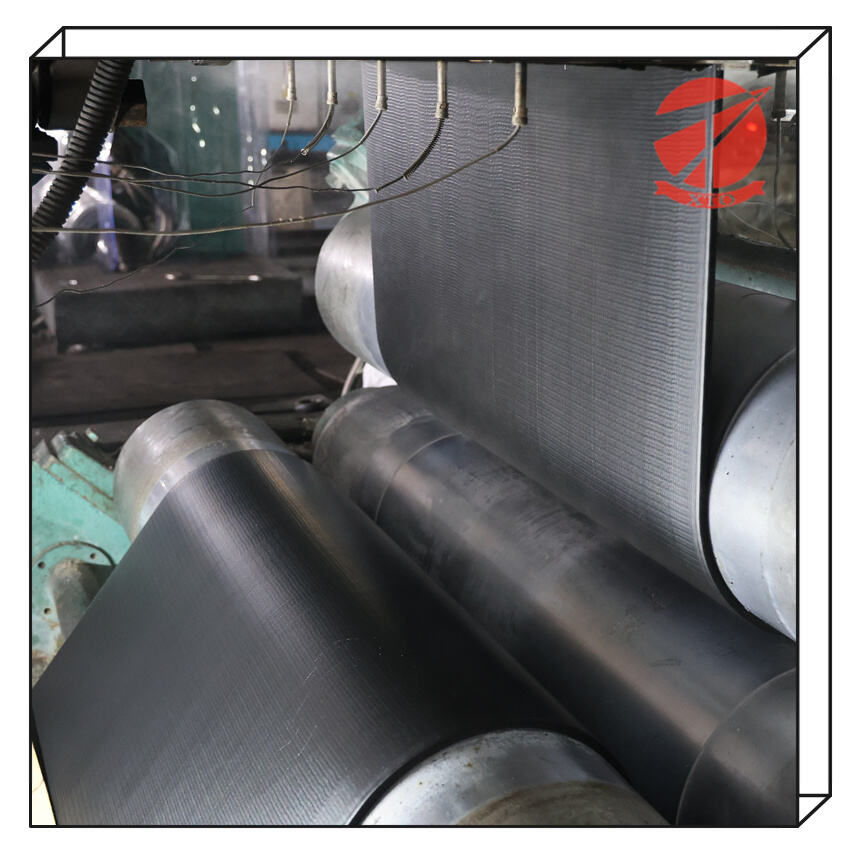

The rubber belting range covers steel cord conveyor belt as well as multi-ply fabric belts. the solid conveyor belt as well as sidewall belt, pipe belt, patterned belt, lifting belt, and an aramid conveyor belt. The annual design capacity of 29 million square meters of conveyor belts. Among them, we have 11 solid woven conveyor belt production lines, 4 multi-ply textile belt producing lines, and 7 conveyor belts made of steel lines. It also has the longest steel cold conveyor belt vulcanization equipment in Asia.