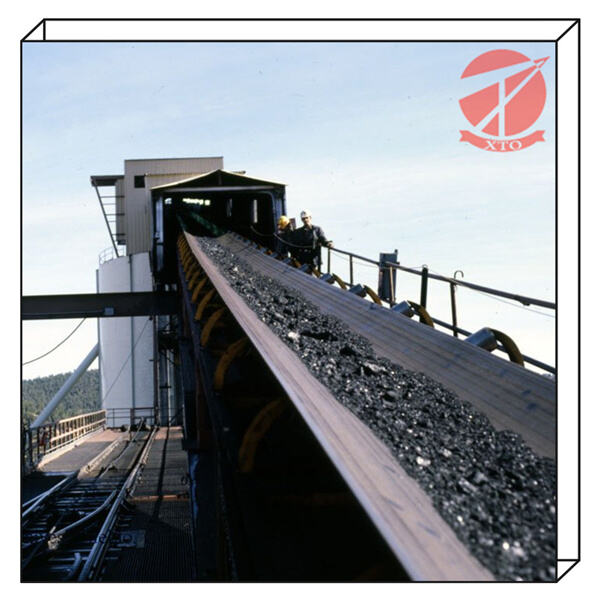

METAL NETWORK CORPORATION Importance of Rubber conveyor belts in the mining industry They are used for conveying items like coal, sand, rocks and ores. These materials are required in many different processes and the conveyor belts allow it to be transported effectively. Well, those belts are made of strong and flexible rubber that literally lasts forever. It is resistant to a rough mining environment (high heat, heavy loads and harsh surroundings) no problem.

The rubber used in a conveyor belt is mixed with steel, fabric and plastic to add stregnth. These are then molded and left in various sizes to fit different belt needs. These belts are put through a series of tests to ensure that they can withstand large loads and function within the standards designed. Testing of this type is critical to measuring the efficacy of belts when put under their ultimate test conditions found in arduous, hazardous mining applications

The utilization of this type needs a silicone conveyor belt which can work in predicted conditions. Made of high-quality durable materials that will last.besides, the belt also is easy to assemble and maintain. Of course, this little supercomputer installation can be done from pretty much a plug and play perspective on site —mainly due to the fact that in an industry moving so fast any thing designed should not only make it safer but also easier for mine workers.

It is strong in nature as it made up of hard rubber conveyor belts. These are chemical, oil and heat resistant. Also because of it powerful, this can cause belt damage which causes mining companies have to pay for repairing and replacing. This in turn means they can then avoid the downtime that comes from having a belt fail or break, which slows mining to an immediate crawl.

In the world of mining, new technologies can arise at any time and each play layer that is to be built contains its own technological advances either newly developed or ones consuming less power. Taking full advantage of ever new technology, rubber conveyor belts have enabled a system that can out-perform anything the past may imagine; increasing in-putting for mining and productivity. A self-healing one in this case, because there are belts available now that re-seal after being sliced. This allows very little time for the continued mining operation to slow down, if at all.

Mining Safety: Manufactured to the highest standards, quality Rubber Conveyor Belts deliver increased safety and efficiency for conveyor systems. The mining industry is known to be extremely dangerous and has some of the highest safety standards around. Apart from the workers, conveyors can also be designed with anti-slip surface and unload buttons which will help prevent any accidents.

The conveyor belt with low noise effectively reduces dust falling and mining environment pollution for the miner. This is important in mining because it can get loud and years of exposure to this noise would mean potential hearing damage. By utilizing reliable quality conveyors, these companies can create improved a safer and more ergonomical working environment for their workers.