Conveyor belts act as moving roads that carry devices from one spot to another. They are in factories, at the airport... and now we can meet them even when shopping. They are useful when it comes to facilitating moving large materials without necessarily having to lift them. One tidbit you may not know is that the rubber involved in conveyor belting plays a huge role in its effectiveness. In this article, we are going to look at why rubber is the most crucial part of conveyor belts and how you should pick one?

There is a material called rubber which helps the belts glide along their track. This is so as it helps them to bear heavy weights without getting broken or dismantled. However not all rubber is the same. Not all rubber is of equal quality. The rubber used is important for these systems to work properly and has a long life. Top notch rubber resists age through wear and tear, heat or cold grusive sunlights as it is chemically treated not to crack nor break apart.

The Eroding Effects of Subpar Conveyor Belts Companies reliant on rubber belts for materials transport and handling can face a plethora of complications if their supplier sources bad rubber. This means that they might not work well and could constantly need repairs, which is very time-consuming or costly. It could in addition make the belt bridges insecure for use. That is why you have to pick an excellent distributor with a material of ballistic rubber. In this case there is certainty that the conveyor belts will work safely and without any problems for a long time.

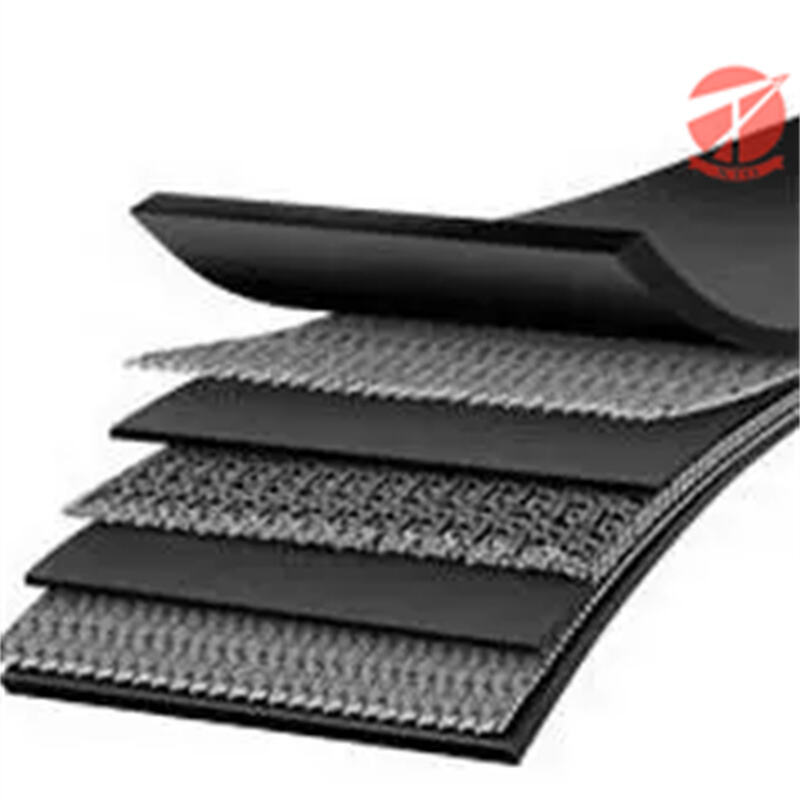

Types of rubber and conveyor belts Mines require a thicker/rubber direction belt often than normal to handle the harsh conditions and heavy weight loads. This is mainly due to the rough nature in which they need to function, making them very susceptible from getting damaged. For food factories, the belts must use rubbershell which is all security and recognized for food producing. It ensures that the chemicals will not fall to food products.

Using the correct rubber also provides a protective barrier from things such as sunlight and other unfavourable environmental conditions for conveyor belts. For example, some types of rubber can weaken if exposed to too much sunlight. Another consideration is improved rubber, which can help again you money on repairs and keep everything running well. Fewer Repairs Longer Lasting Conveyor belts that need less repairs, mean they are able to work continuously.

Belts moving baggage at airports should be particularly stable, so that items do no fall or get stuck. These belts are subject to a wobble and if it occur, they can cause the bags themselves fall creating chaos or even incurring injury. By contrast, belts located in cement factories must be fire-resistant to avoid disastrous accidents. Select the most suitable rubber for conveyor belts to protect staff and prevent costly damage. As such it is crucial to use the worlds best rubber as your work safety matters.

Maintaining conveyor belts involves inspecting them regularly, cleaning any of the parts and ensuring all moving components are lubricated. One of the things to keep them in working order is routine maintenance. Finally, make sure to replace some of those rubber pieces as others are going bad in which its not a good sign and it can lead for accidents when things start falling apart. Old parts need to be replaced so as not lead to further damage later on.

The company boasts modern production equipment, professional management team, and top technology, so that the company has developed into a formidable competitive ability of the enterprise and the PVG conveyer belt holds the highest percentage of the rubber for conveyor belt in China. We are vice-chairman in China's conveyor belt market and also one of the leading makers. The company was awarded the honor of "China Quality brand" and "The most important brand in the area of conveyor belt in China", etc.

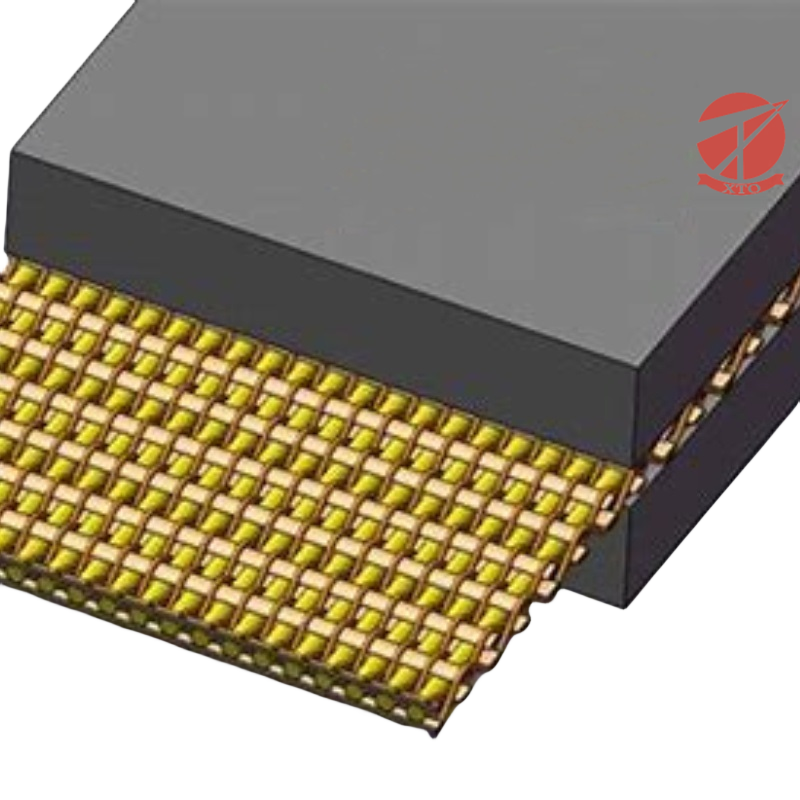

Our product line includes steel cord conveyor multi-ply fabric belts rubber for conveyor belt, pipe with sidewalls, patterned lifting and the aramid belts. We have 11 lines for solid woven belts. There are four lines for multi-ply fabrics, as well as seven lines for steel cord belts. The longest steel conveyor belt vulcanization machine in Asia.

Our RD team includes rubber for conveyor belt accountable for setting national standards. We have 32 patents for national utility models including the "multi-ply fabric conveyor belt", and declared three invention patents and 11 utility model Patents including an ultra-wear-resistant conveyor belt. Our company has joined forces with several universities to highlight its leading position in rubber technology. Additionally, we have an huge and efficient after-service staff consisting of 32 people.

ISO9001, ISO14001 and ISO45001 are stringent standards that we have been able to pass. Our products have been through quality tests conducted by famous organizations like rubber for conveyor belt TUV BV MSHA MASC.