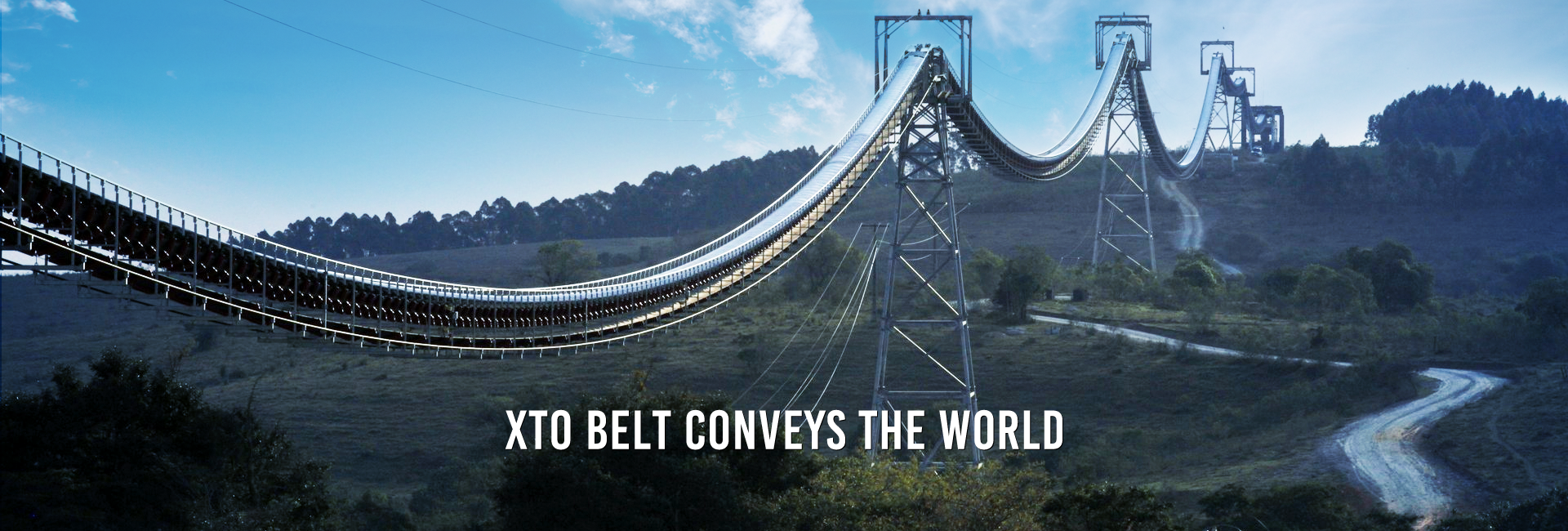

- Introduction

Introduction

Usage

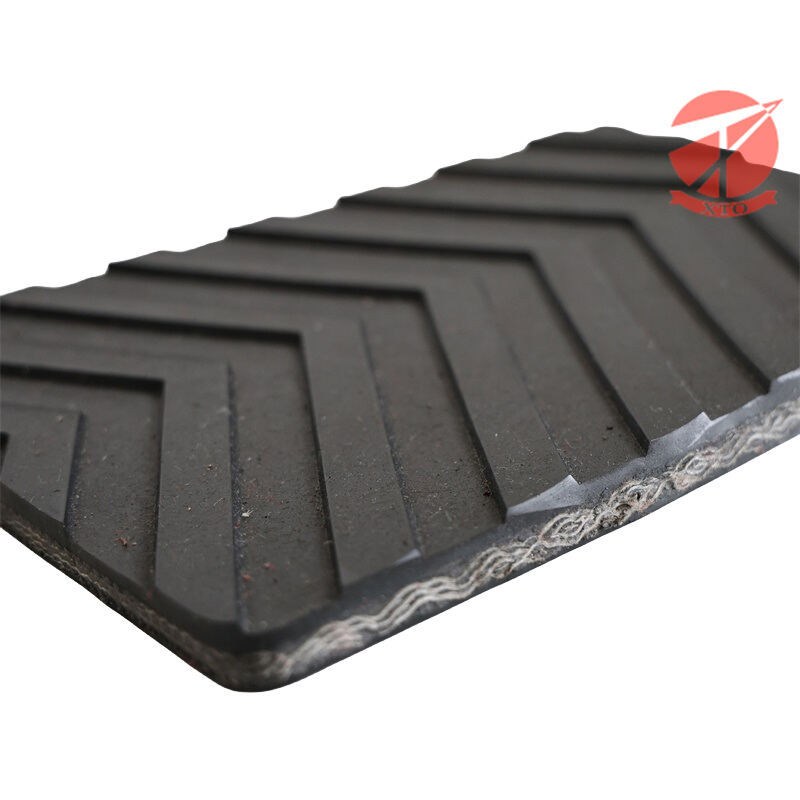

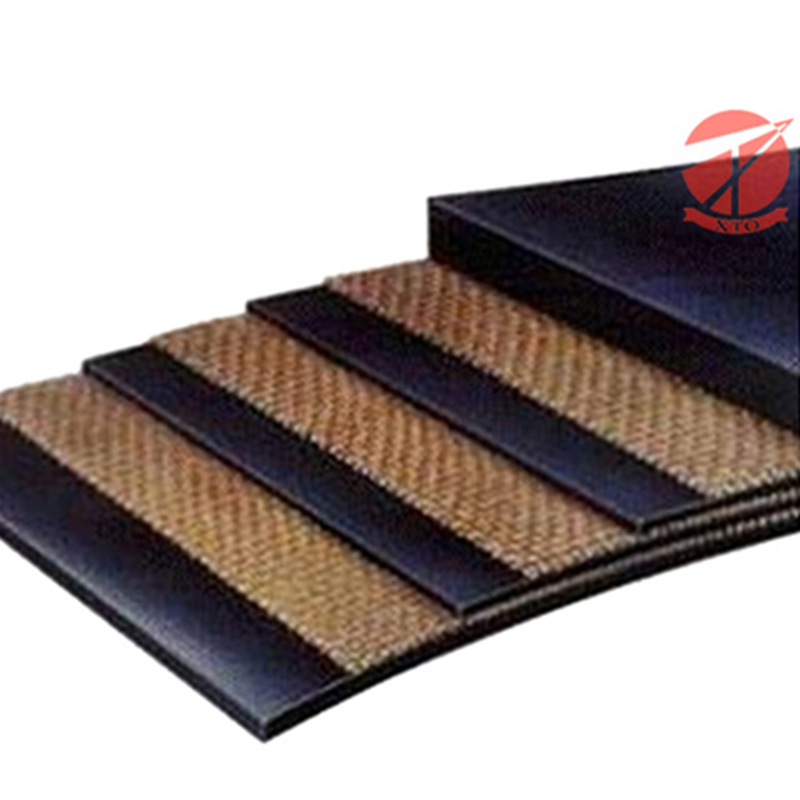

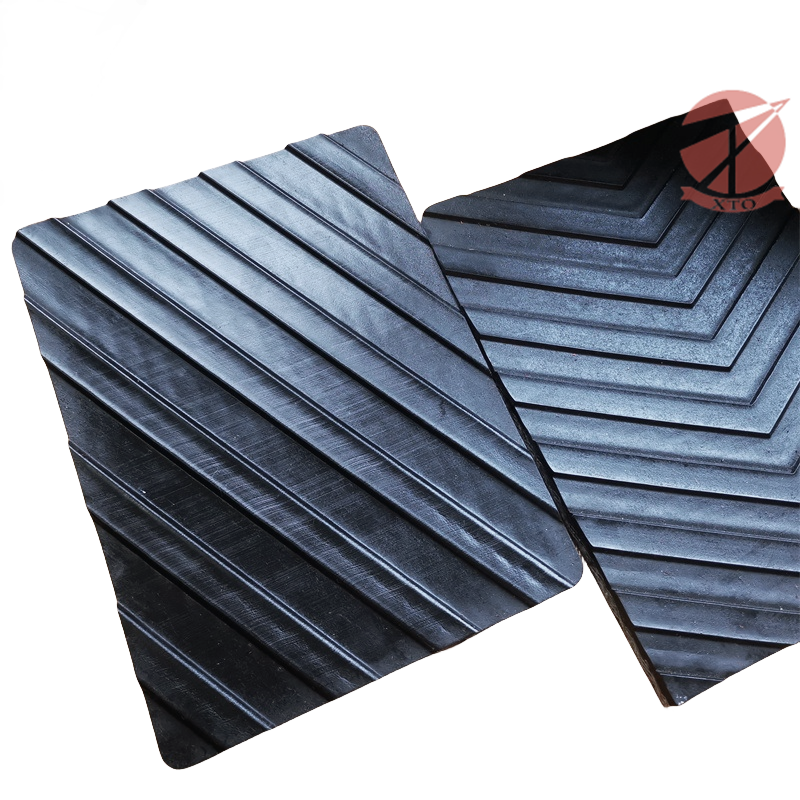

The conveyor belt is composed of the belt body and the pattern part. Due to the different materials transported and the size of the conveyor inclination Angle, the shape and height (depth) of the pattern are also different. The following are several common types: “人”type, “八”type, “V” type

It is suitable for conveying powder, granular and small pieces of material with an Angle of ≤40 degrees, and can also transport bagged materials.

Characteristics

1. Good anti-slip performance: increase the friction between the conveyor belt and the material to ensure the stability of the material transportation.

2. Strong wear resistance: can withstand the wear of materials, extend the service life.

3. Various pattern forms: Suitable pattern shapes can be selected according to different needs.

4. Wide range of application: can be used for conveying a variety of materials, such as ore, coal, etc.

5. High stability: it can maintain a stable operating state during the conveying process.

6. Adapt to different tilt angles: It can be used in a certain slope.

Standard Specifications

| Model | Grade | Tensile strength N/mm | Elongation at break ≥% | Width mm | |||

| Longitudinal | Transversal | Longitudinal | Transversal | 500-2000 | |||

| 680S | Grade4 | 680 | 265 | 15 | 18 | ||

| 800S | Grade5 | 800 | 280 | ||||

| 1000S | Grade6 | 1000 | 300 | ||||

| 1250S | Grade7 | 1250 | 350 | ||||

| 1400S | Grade8 | 1400 | 350 | ||||

| 1600S | Grade9 | 1600 | 400 | ||||

| 1800S | Grade10 | 1800 | 400 | ||||

| 2000S | Grade11 | 2000 | 400 | ||||

| 2240S | Grade12 | 2240 | 450 | ||||

| 2500S | Grade13 | 2500 | 450 | ||||

Rubber Covers

Mine flame retardant: suitable for underground transportation of flammable and explosive dangerous materials, the average value of the combustion test is not more than 10 seconds, the single value is not more than 15 seconds, but also must pass the roller friction test and roadway propane combustion test.

| Standard | Tensile strength Mpa | Elongation at break % | Abrasion mm³ |

| MT914 | 10 | 350 | 200 |