These belts are so helpful since they help in reducing from one place to another and make everyone's work easier. However, in other instances they could be worn or damaged quite easily. This causes numerous problems for factories. This Shandong Xiangtong Rubber Science is why we have something called — Anti-tear Conveyor Belt to our rescue. Let’s learn more about it!

The conveyor belt equipment is a kind of conveying belt used to prevent goods from being torn. It is present to avoid tearing or destroying it. Anti-Tear Conveyor Belt - Most normal conveyor belts are easily broken; the anti-assembly chain is formed from more robust substances. This makes it much stronger so the robot can carry heavy things around without its arm breaking or injuring itself, which is really useful for factories with large parts to move.

Regular conveyor belts are very vulnerable and when damaged, stop to function. This would cost a significant sum of money to buy new belts, so it is also time-consuming taking the load off for just changing some worn-out parts. That is what can ultimately bog down the work and pull back your progress. It also has a efficiency to last longer time and from which any side not be replace it under six months. This Shandong Xiangtong Rubber Science means that the factories can save monet and time, it helps things moving along all smoothly without any blocks.

This distinguishes itself due the Anti-Tear Technology in use. This Shandong Xiangtong Rubber Science technology could significantly reduce the premature wear out of a standard conveyor belt fabric type causing it to burn sooner. It acts as an anti-inflammatory to prevent injury and stop wear from friction. Thus, are provided for a much longer service-life than traditional belts. It also requires less maintenance effort hence fewer repair and more reliability. High-quality packaging equipment that will not fail and can carry the job out.

Anti-Tear Conveyor Belt It is extremely durable. You can really stuff it without worrying about tearing the material, and this is important when high volume in a factory setting. Not only does it last longer, but takes up more time as well and good lubrication can mean a significant savings for your business. Because it is made from high-tensile, strong materials -- factories will save thousands of the money used to buy a new belt or two; as well as suffering less down-time (from broken belts).

Actually, the ANTI-Tear Conveyor Belt is not only stronger, but also safer for staff. This avoids job accidents, being the belt anti-tear. Invent Help Ideas — Standard conveyor belts are susceptible to tearing which results in items falling off. This can lead to injuries. However, the conveyor belt fabric is designed in a way to prevent this from happening.

ISO9001, ISO14001 and ISO45001 are stringent standards that we have been able to pass. Our products have been through quality tests conducted by famous organizations like Anti-tear conveyor belt TUV BV MSHA MASC.

Our Anti-tear conveyor belt team is comprised of experts responsible for setting national standards. And we have obtained 32 utility model patents for national use for example "multi-ply textile conveyor belt" and has issued 3 invention patents, and 11 utility model patents such as ultra-wear-resistant conveyor belts and has partnered with a variety of universities, which shows the company's leading position in rubber industry technology. We also have an huge and efficient after-service staff consisting of 32 people.

PVG conveyer belts have the biggest market share in China. The company is backed by the most advanced production equipment, as well as an experienced management team. We are vice-chairman in China's conveyor belt field and also one of the leading makers. The company has been awarded the title of " Anti-tear conveyor belt" as well as "The most popular brand in the field of conveyor belts in China", etc.

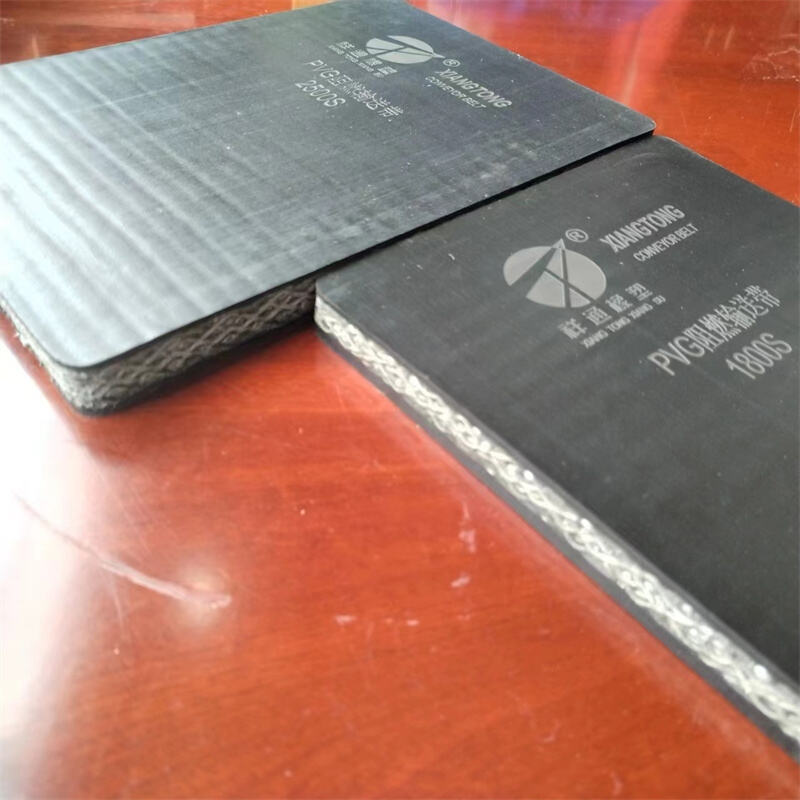

Our product line includes steel cord conveyor multi-ply fabric belts Anti-tear conveyor belt, pipe with sidewalls, patterned lifting and the aramid belts. We have 11 lines for solid woven belts. There are four lines for multi-ply fabrics, as well as seven lines for steel cord belts. The longest steel conveyor belt vulcanization machine in Asia.