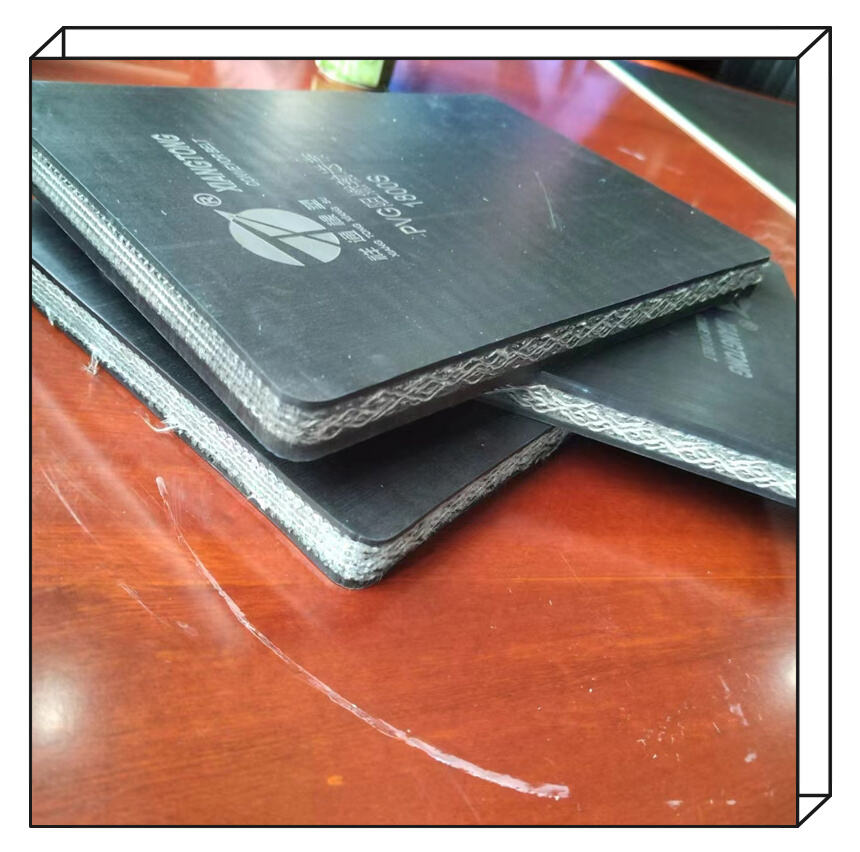

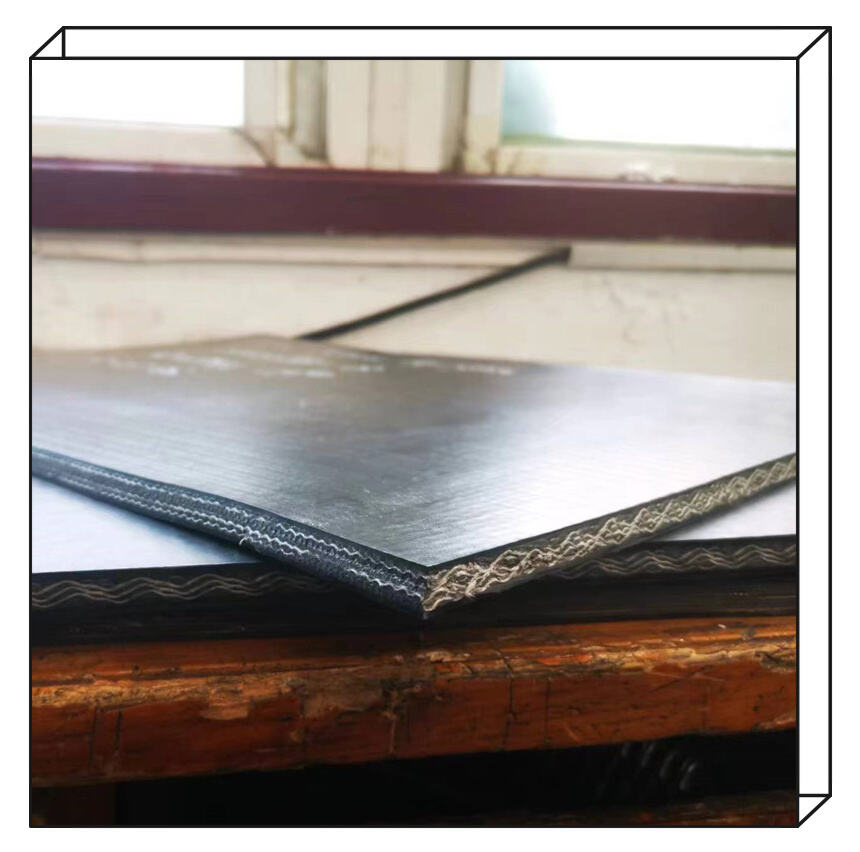

Rubber conveyor belts are highly essential instruments used to transport products in various different locations. They are available in industries like farms, mines, warehouses, etc. They are designed to transport items from one place to another quickly and easily. Fascinating to learn that there are multiple types of rubber used in these conveyor belts. Knowing the advantages of each type will allow you to make an informed decision when selecting the correct belt for your application.

Natural rubber is one of the most widelyused conveyor belt rubbers. This rubber is known as it has a stretchable and very strong property. This podcast is about rubber > it comes from a tree sap so good and eco-friendly stuff. Natural rubber is not well suited to heat, or environments high in chemicals so BE AWARE of that. If you will be using a conveyor Belt that are like these, you have to explore your options

Synthetic rubber is another possibility. Neoprene and Nitrile rubber are two examples of synthetic rubber. These types are designed to withstand oil and other chemicals, making them popular in automotive and chemical production applications. Synthetic rubbers can also be made to endure extremely high or low temperatures. That enables their use in environments that are too extreme to use natural rubber.

There are several key things to consider when selecting the correct type of rubber belt for your conveyor system. The first thing is to take the weight and size of the items you want to move into account. Light and portable or heavy and cumbersome? It will assist you in determining if a heavy-duty or light-duty belt is appropriate for you.

The other thing that needs to be looked into is the type of surface on which one will have to wear it. Smooth belts are really good with flat surfaces, which means that objects can slide without getting stuck. On the other hand, ribbed belts are advantageous for sloped surfaces because they offer friction to prevent things from slipping off. Then there are cleated belts with raised parts to securely hold products and prevent sliding off the belt.

Anti-Static belts are another innovation. In certain industrial sectors, electronic and mining industries, static electricity is extremely different this belts pipes that prevents the formation of it. With help from anti-static belts, it can ensure a safer working environment for companies by reducing accidents.

There are a whole bunch of rubber materials. Now, each type is stronger than the other and more durable. For example, natural rubber is flexible and durable but may not be used in areas exposed to chemicals or high-temperature digits. Conversely, synthetic rubbers such as neoprene and nitrile are resistant to chemicals and capable of accommodating high temperatures; however, they may be less flexible than natural rubber.