Rough top belting is a type of conveyor belt which proves to be really helpful in multiple tasks. The top is rougher, which is meant to keep things in place. This is very crucial for when Continue Reading => During the movement of items through the conveyor it can easily slip off. The contours in its surface assist with keeping the objects secure so that they do not crash down or slide sideways while travelling. Rough top belting is commonly used in areas where large, heavy objects need to be transported such as factories and warehouses. Below mentioned are the various advantages of anti tear steel cord conveyor belt and this text will help you to know more about them. We will also talk about how to choose the proper type, maintain it and the application into different industries.

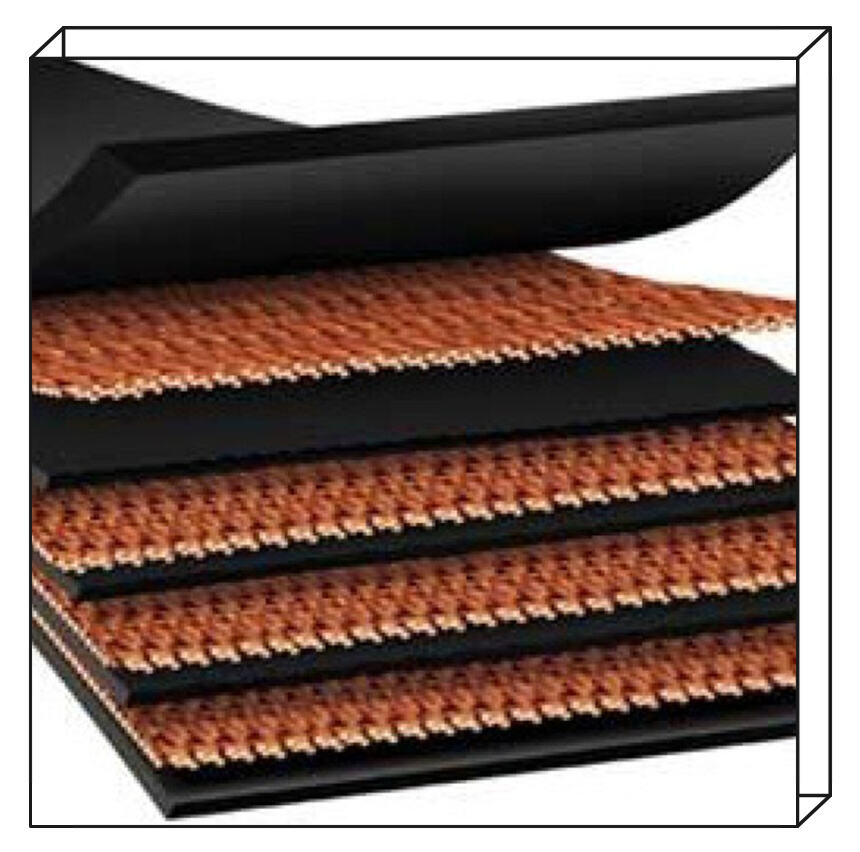

Material Depending on the requirement, rough top belting can be manufactured using different materials like polyester, nylon and rubber. We will also discuss how each material possesses its unique pros and cons. The material will actually depend on your purpose of usage as well as working environment.

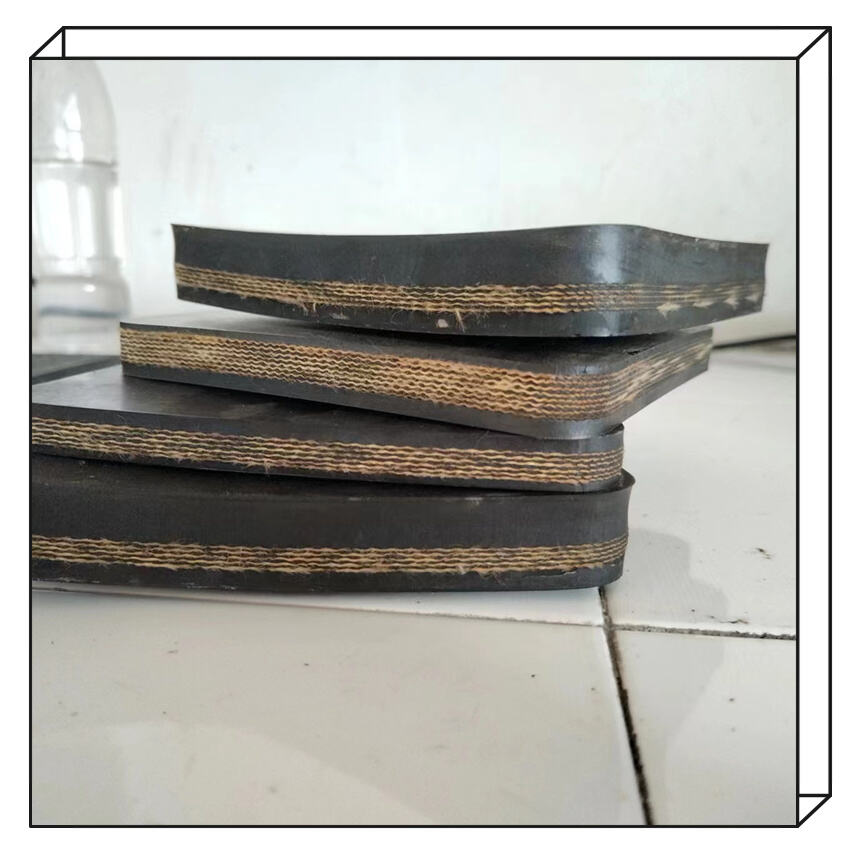

Thickness: The thickness of the belting is another factor that contributes to its strength. Such building the heavier load dareen so thicker belts are much durable and heavier but less or less flexible will be a more problem to soften. These reminded me that thickness and flexibility will vary depending on what you actually need.

Belt Surface Texture: The actual coarseness of the belt can differ from one combination to another. Belt surfaces can be extremely rough, but others may be just a little rough. Choose a texture that is the best for the products you are transferring out. A very rough surface will be necessary for heavy items, a more smooth one should suffice if the items are light.

Width and length: Ensure that the width and length of belting matches to your conveyor system. A short or narrow belt will not work quickly enough and things will fall off. Before you choose your conveyor system, always look at the specifications.

Stay Clean: An important aspect of proper maintenance is the regular cleaning of the belting. Its rough surface may accumulate dirt and debris, rendering it slippery and affecting its performance. Besides this, clean it regularly to maintain the shape.

Routine Inspection: Inspect the belting on occasion to create awareness of any issues before they are out of hand. Check for wear, cracks or related damage that may impact the performance of the belting. By catching issues early, you can save time and money.