Reinforced rubber belting is a type of anti tear steel cord conveyor belt that is used in various industries to ensure that machinery or equipment operates smoothly. What makes this kind of belting truly strong and rugged is both the material and the manufacturing process, which makes it an ideal selection for safe transport of bulky and heavy objects.

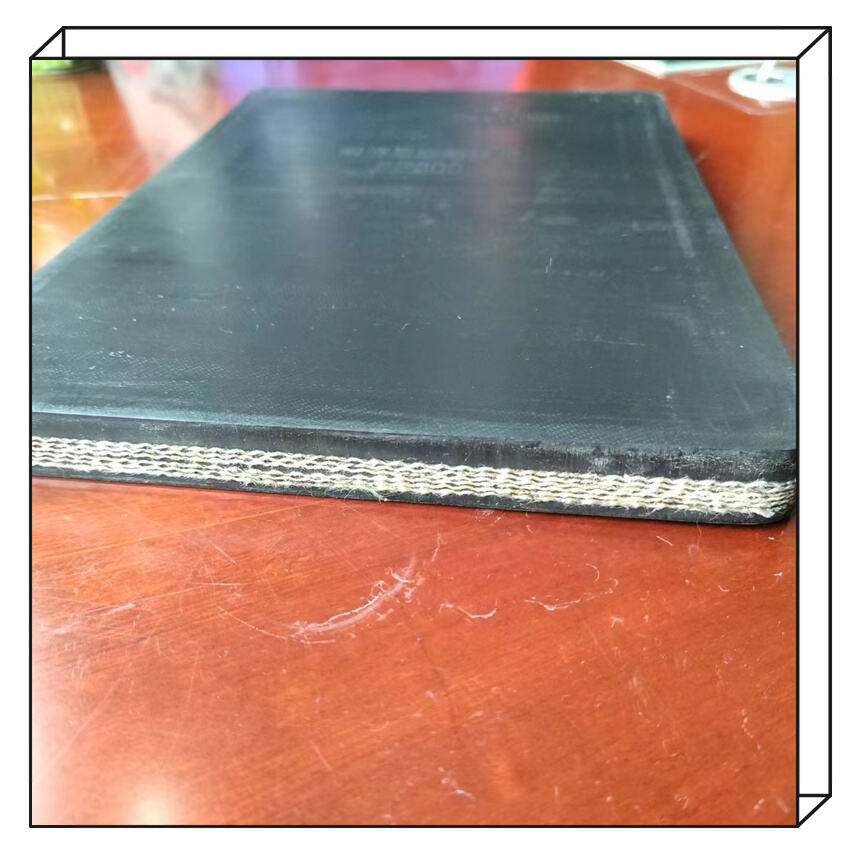

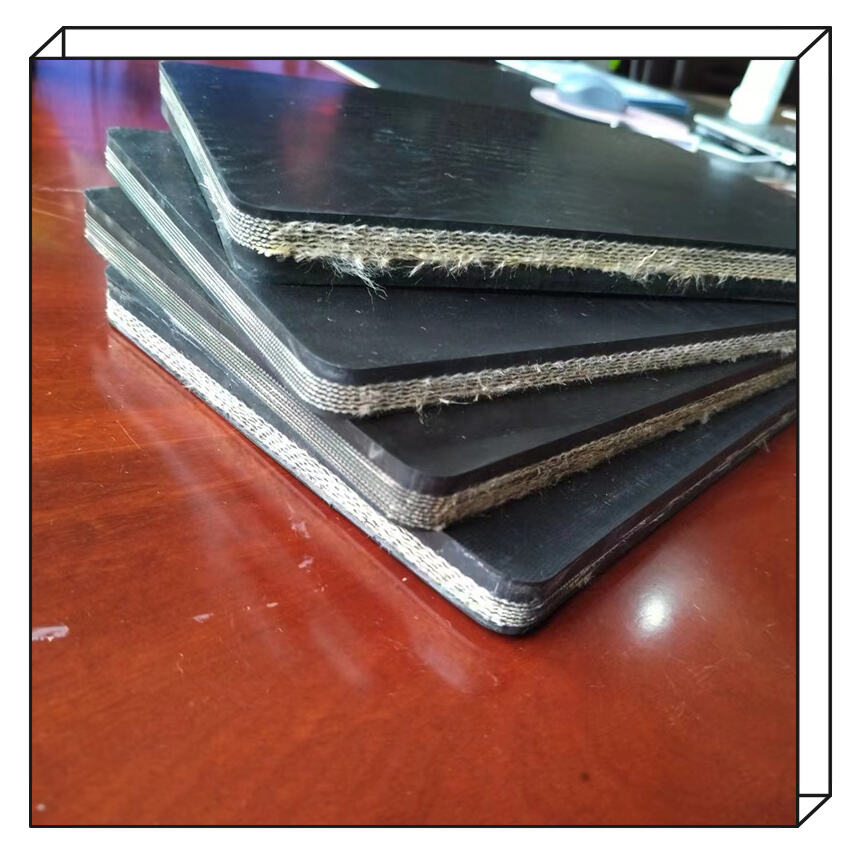

This rigidity and durability of reinforced rubber belting is primarily why so many choose this material. This has multiple layers of rubber, which allows a good protection of this belt from the damage. And the layers in this make it durable and enables it take a lot of pressure and force without breaking. This allows it to be used in many diverse environments like mines, construction sites, and factories where heavy work is performed.

The advantages of assembly line conveyor systems make it the best choice for heavy-duty applications across various industries. First off, it’s extremely durable, meaning it won’t crush even under heavy loads. This is essential for enterprises required to transport heavy-duty materials. It also resists damage from chemicals, water, and other harmful substances, making it ideal for harsh conditions where other materials might be compromised.

Reinforced rubber belting is truly very versatile and can be used for application across a wide spectrum of jobs. It is used in everything from moving items across conveyor belts, to assisting in product manufacturing. This belting is compatible with a variety of machines and equipment, so it is readily available to businesses, with little adjustments needed to their current systems.

The fact that it protects machines from damage is one of the biggest polymer reinforced rubber belting advantages. Using this type of belting properly usually creates less wear and tear in machinery, helping them to last longer. This ensures that businesses do not have to deal with costly repairs and wasted time that arises when any company is forced to stop business operations. Organizations can take steps to ensure that they are using the best material to keep their machines running properly for a long period of time by using high quality reinforced rubber belting.

Reinforced rubber belting also provides another smart advantage when it comes to enabling companies to work more efficiently and quickly. Such durable belting is meant to hold up through years of service, so that companies don’t have to constantly worry about repairs or replacements. This kind of durability enables companies to get back to work without any interruptions. It can also streamline things, making processes more efficient and thus, increasing productivity and ultimately, profits for the business.

And finally, reinforced rubber belting is highly flexible and useful to so many different types of jobs and applications. You can find it in different equipment; conveyor belts, packaging machines, etc. Works on a great array of materials and machinery. This flexibility enables businesses to adjust rapidly to market changes and stay current to new technologies

We have a skilled RD team with experts who are creating national standards. We have 32 patents for national utility models including the "multi-ply fabric conveyor belt", and declared reinforced rubber belting and 11 utility model Patents, such as an ultra-wear resistant conveyor belt. Our company has worked with various universities to show its leadership position in rubber technology. We also have an extensive and highly skilled after-service department made up of 32 people.

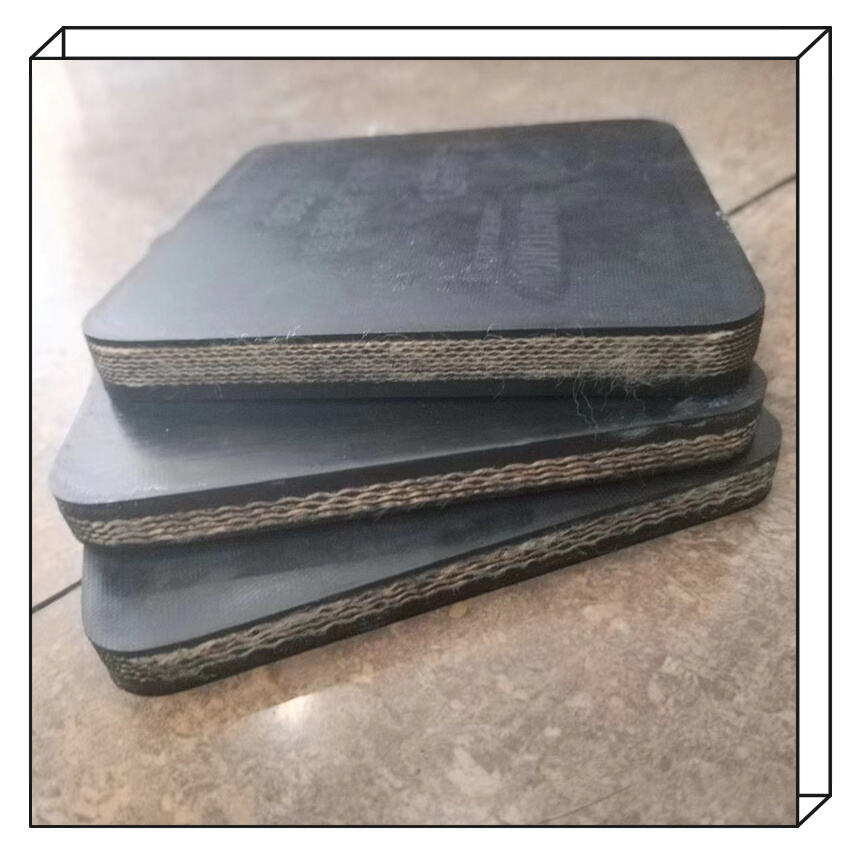

The product line includes conveyor belts made of steel, multi-ply textile belt, solid woven conveyor belt and sidewall belts, pipe belts, patterned belt, lifting belt and aramid conveyor belt. The annual design capacity of 29 million square meters of conveyor belts. Among the belts: We have 11 conveyor belts that are solid woven production lines, four multi-ply textile belt production lines, and seven conveyor belts produced by steel lines. We also have the longest steel conveyor belt vulcanization machine cold in reinforced rubber belting.

ISO9001, ISO14001, and ISO45001 are rigorous standards that we've successfully completed. Our products have been through quality tests conducted by renowned organisations such as RWE reinforced rubber belting BV MSHA MASC.

The company has advanced production equipment, a professional management team, and first-class technology to ensure that the firm has become a renowned competitive enterprise The PVG conveyor belt is the reinforced rubber belting of the market in China. We are vice chairman of China's conveyor-belt field, and is one of its leading makers. The company has been awarded awards such as "China Quality Brand" and "The Most Influential Brand in the Field of Conveyor Belts in China" and many more.