When people stop using old conveyor belts, have you ever wondered where they went? Previous models they simply used to discard in addition to without a doubt pile up inside of rubbish dumps. Thus a problem arose because, as we all know, landfills are not only filled quickly but it's also harmful to nature. However, companies such as Shandong Xiangtong Rubber Science turned these old conveyor belts into something reusable – resistance bands.

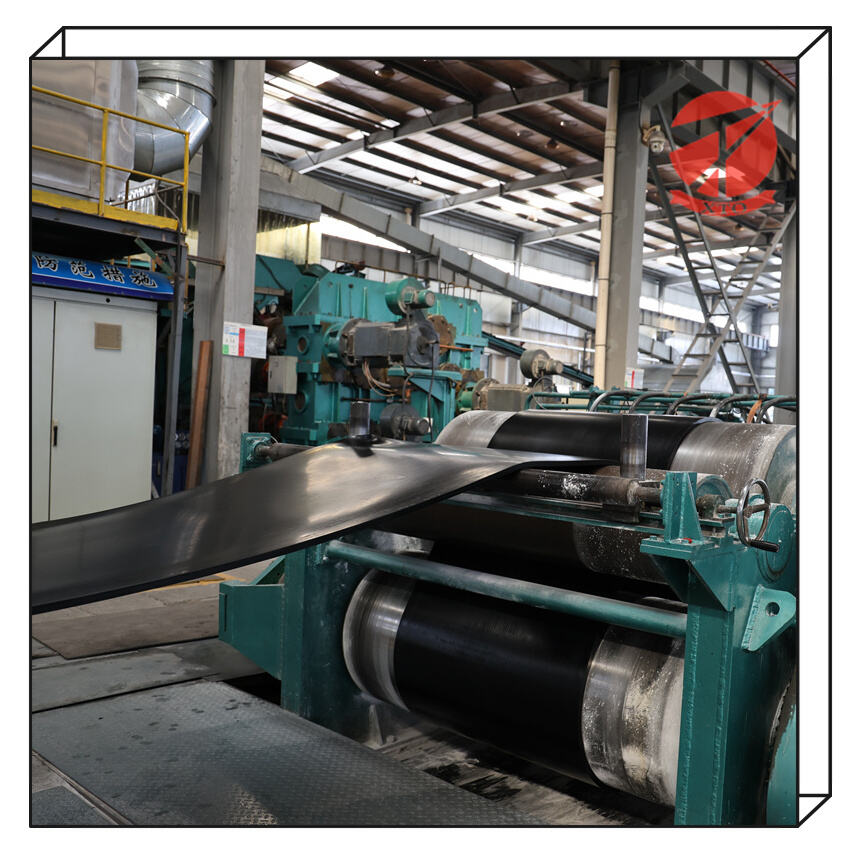

There are very different jobs and industries where anti tear steel cord conveyor belts can be used. They are commonly utilized in mining, farming, construction, or even at the airport. This durability means these belts can sustain heavy loads and function in even the most extreme conditions. For companies going about their business, this means the world to them that they can rely on the equipment doing its job.

The second advantage is that assembly line conveyor systemss are often stiffer than new belts. They are less prone to breaking or wearing down easily, because they have already gone through tests of use. And this makes it easier for the companies to put their trust on the materials for very long years, which is a great plus, since the budget and planning-wise they do not have to reassess its location.

There are many common beneficial ways that recycled conveyor belts help the environment. For one, because they are made from recycled materials rather than virgin materials, help minimize the consumption of resources. This also means that they require less energy to manufacture, which is a plus point for Mother Earth. Using less energy means less pollution and fewer greenhouse gases, which makes the world a nicer place to live in.

Moreover, this prevents old conveyor belts from going to waste which in turn reduces the overall amount of waste making it to the landfills. This matters, because landfills breed environmental and human health issues in neighboring communities. This helps preserve the planet for generations to come, and so by recycling these belts we are doing our bit.

The companies such as Shandong Xiangtong Rubber Science are the reason that the future of making conveyor belts are looking strong. With a rising number of industries beginning to embrace the use of recycled conveyor belts, the need for such materials may become more widespread. It's exciting to know that more businesses will be searching for solutions to become environmentally sound.

Furthermore, companies can save costs on replacements because recycled conveyor bands are sturdy and durable. This ultimately leads to these companies saving even more as time goes on due to the purchase of recycled conveyor belts instead of continually purchasing brand-new ones. This pretty much financial benefit comes in very useful as organizations begin to plan out their budget.