Moving belts equipment has a great advantage to transport materials because they provide fast movement from one place to the other. Rather than having humans move the items by hand, which is labor intensive and can be slow, землерийний конвеєр does all of this heavy lifting with far greater speed. This allows workers to conserve their energy and spend their time on other critical tasks that utilize those talents. As you have them focusing on the factory/assembly line where workers can create things that require critical thinking, focus, fundamental business knowledge & expertise, it's going to boost the overall productivity of the factory. Well, factories can produce more products in less time which is good for business.

Moving conveyors are also capable of handling materials long-distance, which makes relocation simple and without difficulty. This is particularly valuable when materials have to be transferred from one area of the factory to a secondary location that is some distance away. Let's say you have a factory where it's split into different areas that create various products: conveyors can move significant volumes of materials in an efficient, timely manner. This allows workers to speed up their work flow and enables the factory to run efficiently.”

While factory workers have a long and rich history of working on конвеєрна стрічка зі сталевого шнура проти розривуs, they can also be very beneficial in warehouses. Warehouses are where a large part of pieces stored before they go out to the customers. The benefits of moving belts in warehouses include reducing the work for employees. Moving box and materials manually is cumbersome as it requires a lot of energy to move them; the moving belt can easily transfer heavy materials without much effort. This allows employees to focus on other important things that can improve the warehouse.

Higher mobility belts allow work to be much easier, but they also help in increasing the accuracy of moving items inside warehouses. The moving belts are programmed to deliver materials to designated spots in the warehouse. In short, it guarantees that items are where they need to be for warehouses moving through a high volume of products quickly. Proper storage of items allows workers to find items when they are needed, thus saving time and preventing mistakes.

Nevertheless, if you are going to have an assembly line, you should utilize moving belts to your advantage. An assembly line is a place where various components are assembled into a final product. Moving belts play a key role in assembly line techniques, offering the primary advantage of shortening the time it takes to complete each step of the process. Moving belts provide fast and easy transportation of material — when they're available, workers can settle into their craft without worrying about where to move stuff.

Assuming belts in an assembly line is another lucrative benefit, it reduces the risk for errors and accidents. As moving belts can be programmed to move materials to certain spots, this minimizes the likelihood of items being misplaced or lost. This makes the process of putting things together easier when the materials get delivered in all the right places. Conveyor systems also help employees avoid physical strain and injuries because moving belts assume the laborious transporting and lifting of materials. This results in a safer environment for all.

Logistics, or moving things around from place to place, relies a lot on moving belts. Reducing the time taken to transport materials is one of the main ways how moving belts can improve logistics. This is important especially in time-critical scenarios such as delivering fresh food or other items that need to be delivered quickly. Fast handling with rubber bands and moving belts is essential for happy customers.

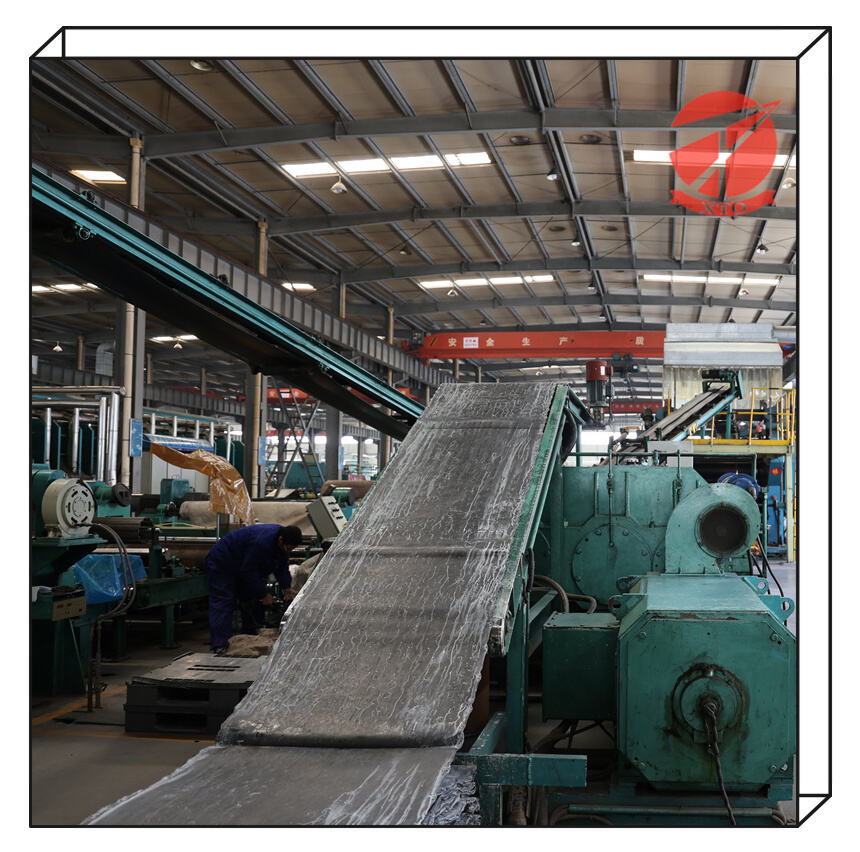

The company moving belt modern production equipment, a professional management team, and top technology, so that the company has developed into a formidable competitive advantage for the business The PVG conveyor belt is the largest share of the marketplace in China. We are vice-chairman of China's conveyor belt industry, and is one of its leading makers. Our company has been awarded distinctions like "China Quality Brand" and "The Most influential Brand in the field of Conveyor Belt in China" as well as other awards.

ISO9001, ISO14001 and ISO45001 are stringent standards that we have been able to pass. Our products have been through quality tests conducted by famous organizations like moving belt TUV BV MSHA MASC.

Our moving belt of products includes steel cord conveyor, multi-ply fabric belts, solid braided belts, pipe with sidewalls, patterned lifting and aramid belts. We have 11 lines of solid woven belts, four lines for multi-ply fabric, as well as seven lines for belts made of steel. It also has the longest steel conveyor belt vulcanization machine cold in Asia.

We have a highly skilled RD team with experts who are setting national standards. And we have obtained 32 national utility model patents like "multi-ply conveyor belt made of moving belt" and has issued a total of 3 invention patents as well as 11 utility model patents such as ultra-wear resistant conveyor belt, and has partnered with a number of universities, which shows the company's leading position in rubber industry technology. We also have an extensive and efficient after-service team made up of 32 individuals.