- Einführung

Einführung

Verwendung

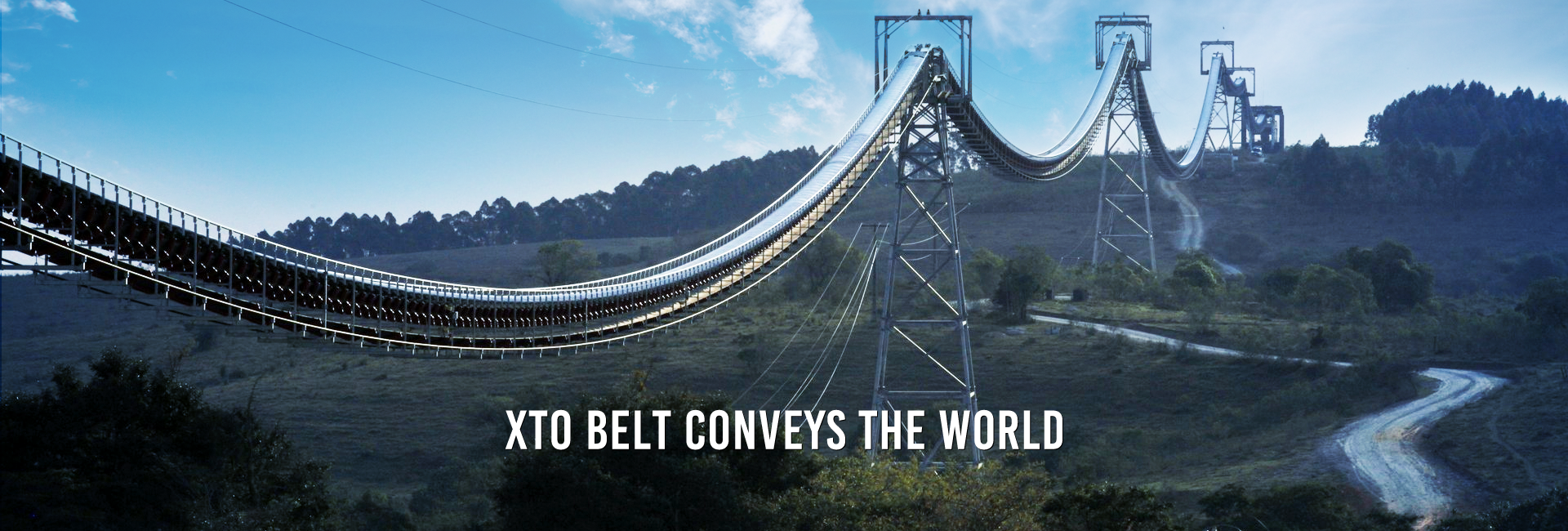

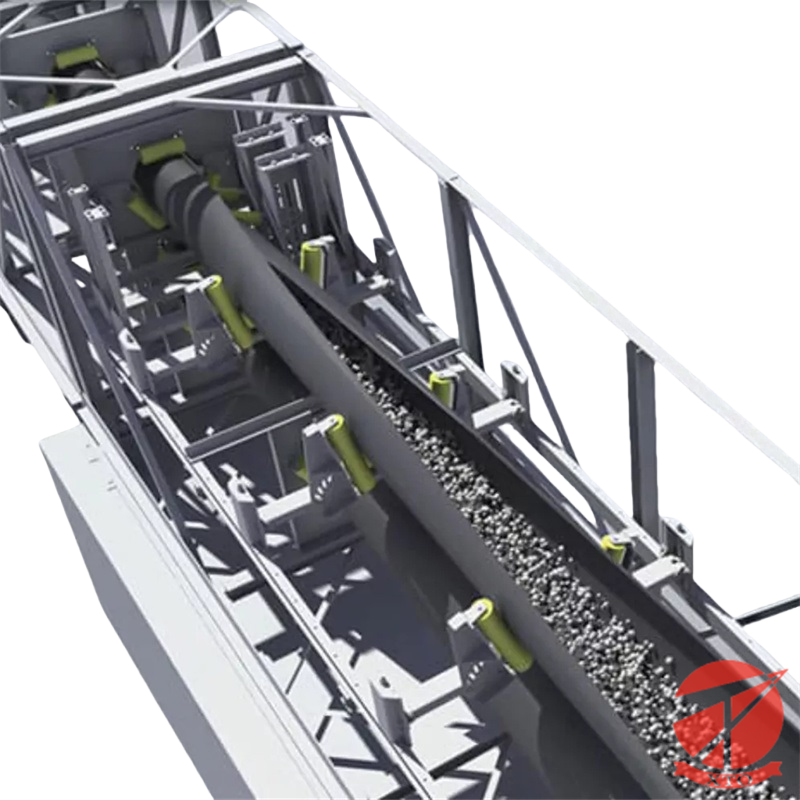

Der Pipe Multi-ply Textilförmige Fördergurt ist ein neuer Typ von Fördergurt, der EP/NN als Leibstoff verwendet und auf der Arbeitsseite hochelastisches, hoch verschleißfestes und hohe Festigkeit aufweisendes Gummi. Er wird hauptsächlich zur Förderung von Materialien verwendet, die leicht verunreinigt werden können, wie z.B. Pulver oder körnige Materialien. Beim Betrieb ändert sich der Gummigurt von einer flachen Form zu einer U-Form und schließlich zu einer Rohrform, wobei das Material eingeschlossen wird und der Prozess des geschlossenen Transports realisiert wird.

Eigenschaften

1. Geschlossener Materialtransport, sowohl den Materialien als auch der Umwelt zugute kommend.

2. Steilwinkeltransport, der Transportwinkel kann normalerweise 30° erreichen.

3. Die Förderlinie kann gemäß der Raumkurve angeordnet werden.

Technische Details

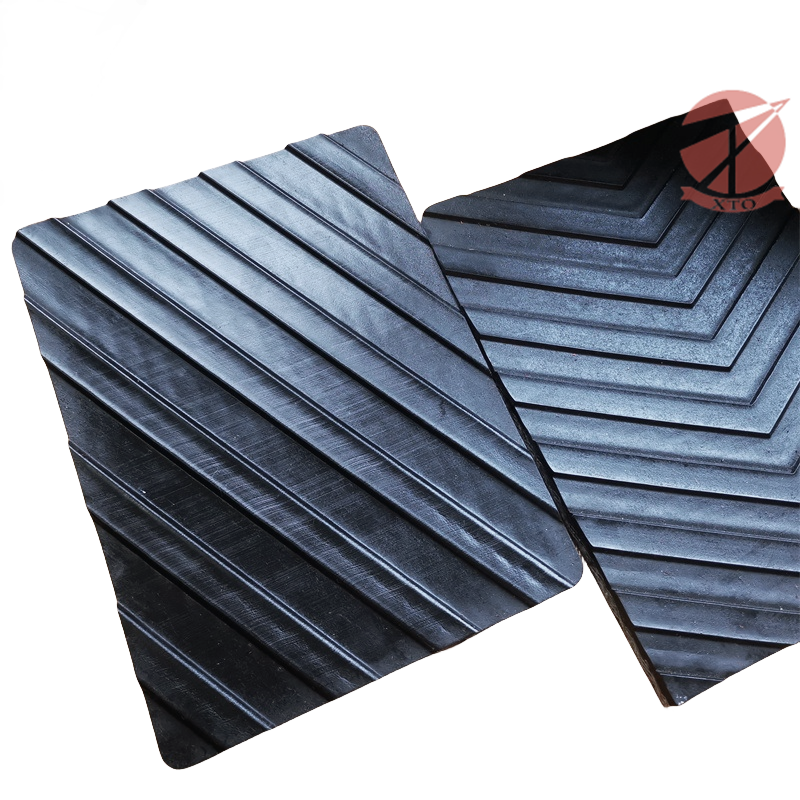

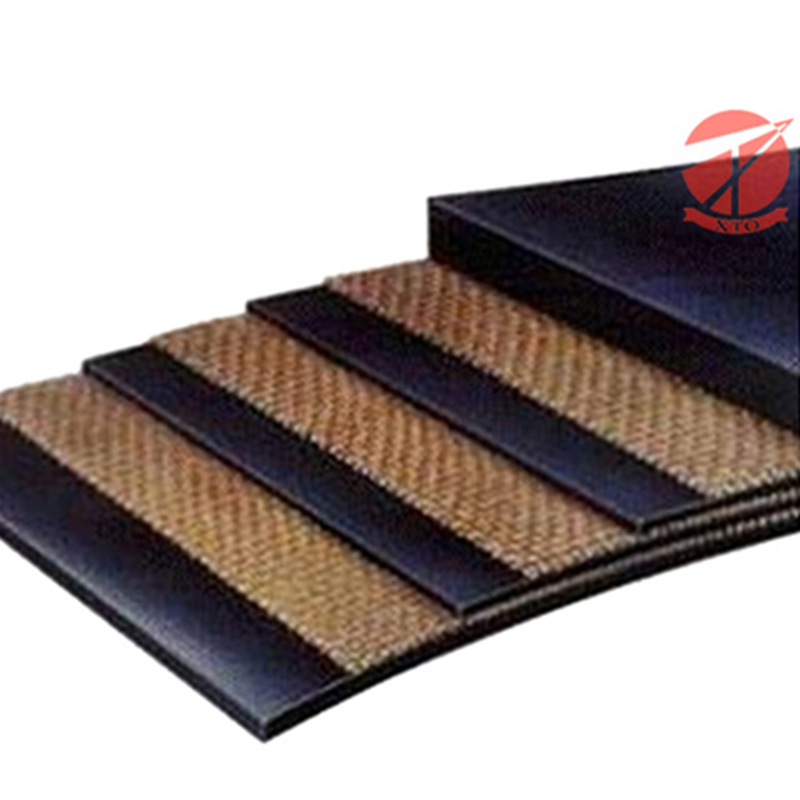

1. Trägermaterial: Normalerweise werden Polyester, Nylon und andere hochfestige Fasermaterialien verwendet.

2. Fördergurtstärke: nach den unterschiedlichen Anwendungsanforderungen und der Lastfähigkeit entworfen.

3. Überzugsmaterial: wie Kautschuk, PVC usw., um verschleißbeständige und rutschsichere Eigenschaften zu bieten.

Standardspezifikationen

| Stärke (KN/m) | Anzahl der Schichten | Rahmentyp | Gürtelbreite | Rohrdurchmesser (mm) |

| 300 | 2-4 | NN/EP | 500-2400mm | 100 150 200 250 300 350 400 450 500 550 600 |

| 400 | 2-4 | NN/EP | ||

| 500 | 2-5 | NN/EP | ||

| 630 | 3-6 | NN/EP | ||

| 800 | 3-6 | NN/EP | ||

| 1000 | 3-6 | NN/EP | ||

| 1250 | 3-6 | NN/EP | ||

| 1400 | 3-6 | NN/EP | ||

| 1600 | 4-6 | NN/EP | ||

| 2000 | 4-6 | NN/EP |

Hinweis: Es kann je nach Kundenanforderungen angepasst werden.

Deckungsgrade

Gemäß HG/T 4224-2011 Standard

| Qualitätsstufe | Zugfestigkeit min. (ISO37) Mpa | Dehnung bei Bruch (ISO37) % | Verschleiß max. (ISO4649) mm³ | Änderung der Zugfestigkeit und der Bruchdehnung nach thermischer Alterung % |

| H | 25 | 450 | 120 | -25 ~ +25 |

| D | 18 | 400 | 90 | -25 ~ +25 |

| L | 20 | 400 | 150 | -25 ~ +25 |

| 1. Ozonwiderstandstestbedingungen: (50±5) pphm, 40±2°C, Dehnung: (20±2)%, Zeit 96 Stunden. 2. Thermischer Alterungstest: 70°C×168h | ||||

Die Werte helfen dabei, das geeignete Deckungsmaterial für die Anwendung oder für die zu transportierenden Materialien zu bestimmen. Eine zuverlässige Beurteilung des Verhaltens der Deckungen im Betrieb hinsichtlich Verschleiß- und Schnittwiderstand kann nicht allein aus den Werten der Zugfestigkeit und des Verschleißes abgeleitet werden.