he You work with the conveyor belt you hear that sometimes you need to connect two ends of the belt together. This is known as splicing. Splicing is where you are making the belt a complete loop again so that it can work correctly. And this must be done safely and correctly to ensure that everything works as intended. Here is a simple and straightforward guide to help you step by step on antirivningstransportband av stålkord.

Firstly, you need to prepare the ends of the belt before you start splicing the conveyor belt. Use a belt cutter or a sharp knife to trim away any worn or damaged sections. The ends of the belt must be square/flat, this is extremely critical. This will help the splice stay together when you tape the two ends together.

The next step would be to measure how much of the belt you want to splice. Measure the belt that has to be attached using a tape measure. Once you have measured it use chalk or a marker to clearly mark the ends of the belt. Using a high quality tape measure in this task will prove a great deal easier and help in achieving accuracy in your measurements.

Now, let’s connect the two ends of the belt. To accomplish this, a special joining tool is required. You should match the width of this tool to your conveyor belt. Furthermore, this tool must be able to apply heat to the ends of the belt. As the belt material softens from the heat, it makes it way easier to join the two ends. When your joining tool is prepared, use it to press the belt ends together. This step is really critical for a solid splice.

Once you have melted the ends of the belt together, you must also press them down tightly. In this case, use a pressure roller to maintain a uniform pressure over the splice. Be sure to run the roller from end to end, this will serve to maintain the alignment and straightness of the belt ends. It helps to make sure that the splice is in place and will work well once in use.

After pressing the ends together, you need to allow the belt to cool. You need to let the spliced region cool down for at least a day. This cooling period is extremely vital as it allows the splice to cure and gain strength. The splice does not debond until the belt has reached its full curing temperature.

Please remember to be very careful when handling conveyor belts, they can be dangerous if you are not careful. Here are some important safety tips for when you are splicing to ensure that you remain safe when you are splicing:

Our how to splice a conveyor belt team is comprised of experts responsible for setting national standards. And we have obtained 32 utility model patents for national use for example "multi-ply textile conveyor belt" and has issued 3 invention patents, and 11 utility model patents such as ultra-wear-resistant conveyor belts and has partnered with a variety of universities, which shows the company's leading position in rubber industry technology. We also have an huge and efficient after-service staff consisting of 32 people.

ISO9001, ISO14001, and ISO45001 are rigorous standards that we've successfully completed. Our products have been through quality tests conducted by renowned organisations such as RWE how to splice a conveyor belt BV MSHA MASC.

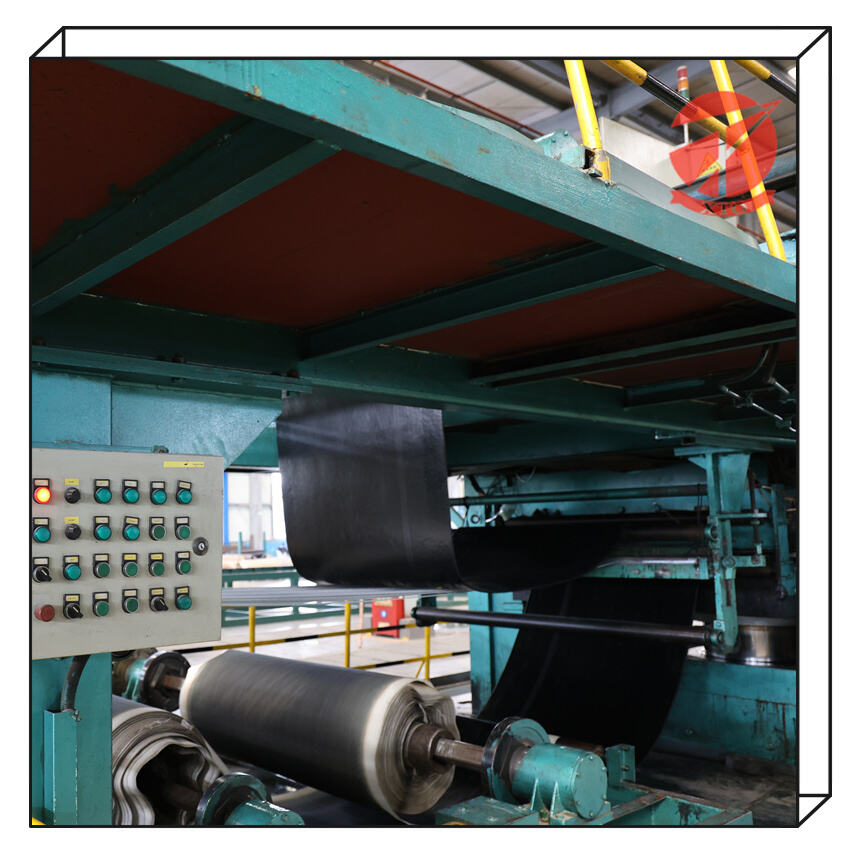

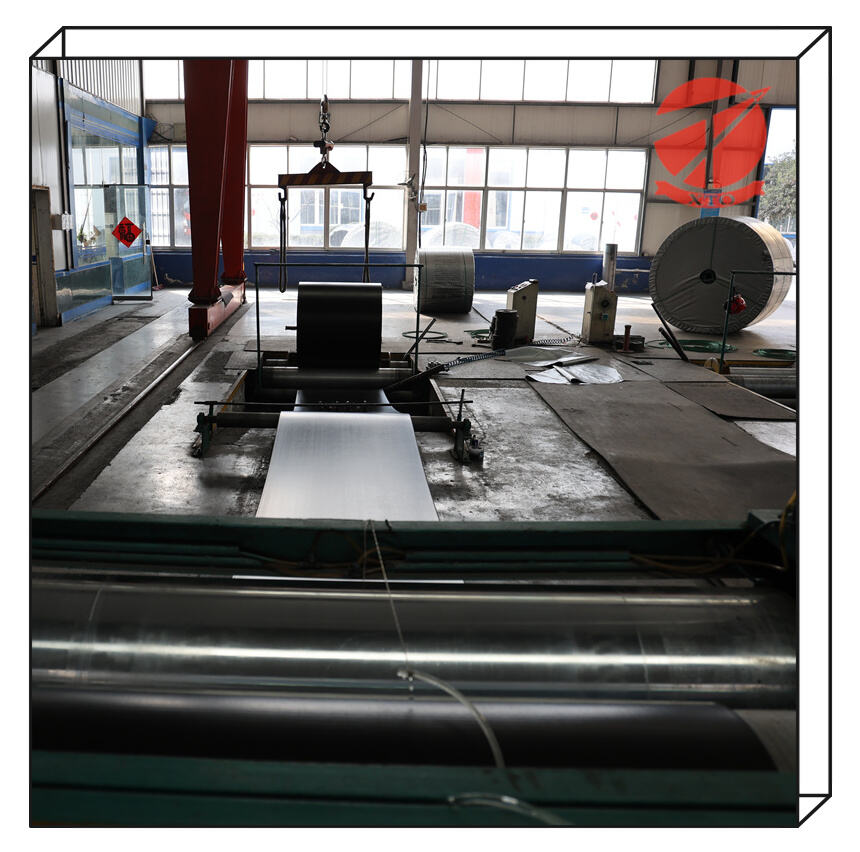

The product line includes conveyor belts with how to splice a conveyor belt multi-ply textile belt solid woven conveyor belt, as well as sidewall belt, pipe belt and patterned belt, as well as lifting belt, and aramid conveyor belt. The annual production capacity of design is 29 million square meters of conveyor belts. Among these: We have 11 solid woven conveyor belt producing lines, we have 4 multi-ply textile belt producing lines, and seven steel cord conveyor belt producing lines. The longest conveyor belt made from steel vulcanization equipment in Asia.

The company has how to splice a conveyor belt, an experienced management team, and first-class technology. The company has developed into a formidable competitive advantage for the business and the PVG conveyer belt holds most of the market in China. We are the vice chairman in China's conveyor belt sector and are among the top makers. The company was awarded the honor of "China Quality brand" and "The most influential brand in the field of conveyor belt in China", etc.