- Introduction

Introduction

Usage

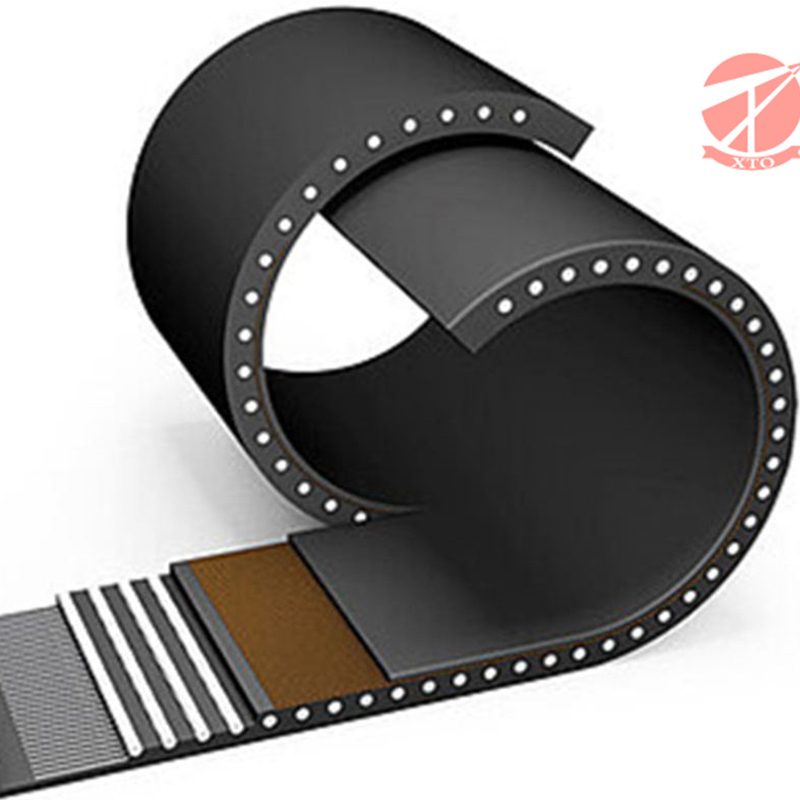

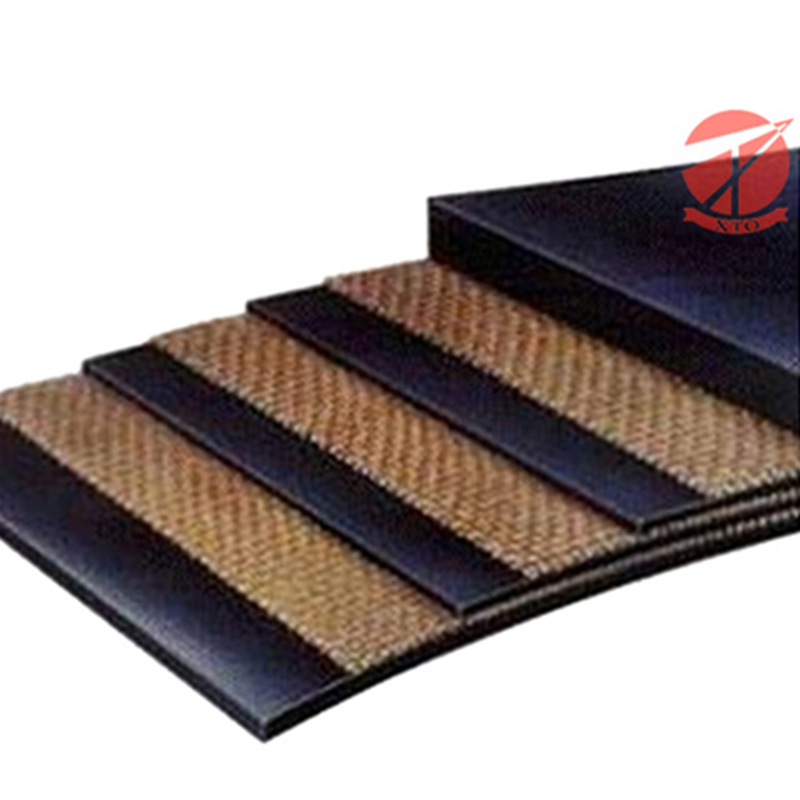

Pipe steel cord conveyor belt is a new type of transportation product composed of steel wire rope as the core skeleton and high elasticity, high wear resistance and high strength rubber as the working surface. It is mainly used for conveying powder, granular and other materials that are easy to pollute the environment. When working, the tape gradually changes from a plane to a U-shape, and finally becomes a tubular shape, which covers the material and realizes the closed transportation.

Characteristics

1.Reduction of maintenance and cleaning costs due to avoiding spillage and loss of material along the conveyor

2.Protection of the conveyed material from external influences like dust, rain or wind

3.Protection of the environment from pollution by the conveyed material

4.Large Angle transmission, transmission Angle is usually up to 30 degrees;

Technical Details

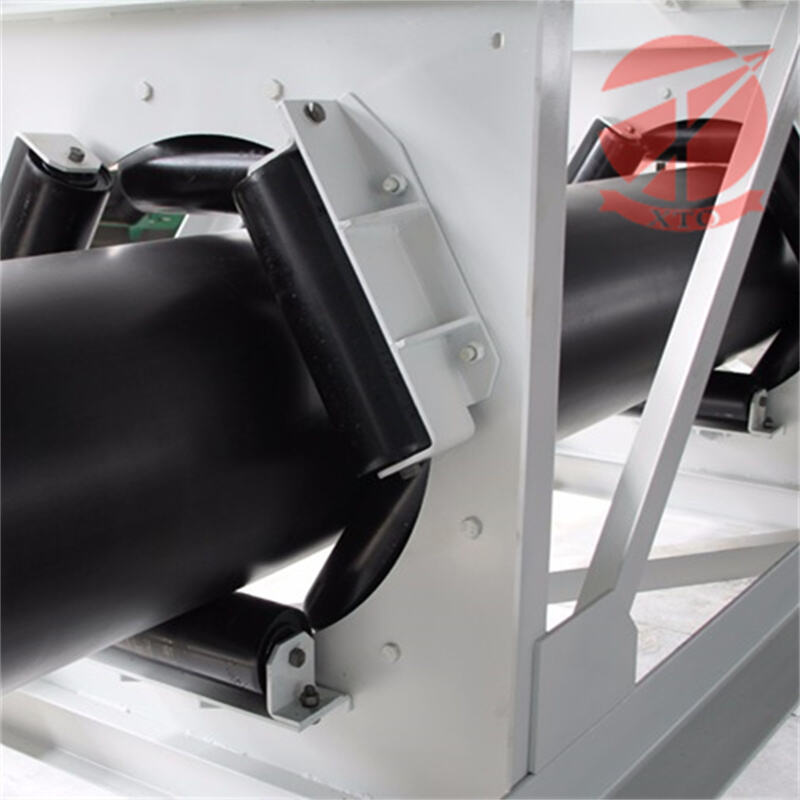

1.Pipe belt can be guided through tight horizontal and vertical curves as it is supported by a set of 6 idlers. This results in the reduction of transfer points and an improved adaption to the existing topology of terrain or existing factory buildings

2.Higher inclination angles can be achieved as the inner side of the Pipe offers more contact surface to the conveyed material compared to a regular conveyor belt

Standard Specifications

| Model | Tensile Strength(N/mm) | Cord Pitch (mm) | Cord Diameter (mm) | Min Cover thickness (mm) | Width (mm) | Pipe diameters (mm) |

| ST630 | 630 | 10 | 3 | 4 | 800-2400 | 100 150 200 250 300 350 400 450 500 550 600 |

| ST800 | 800 | 10 | 3.5 | 4 | ||

| ST1000 | 1000 | 12 | 4 | 4 | ||

| ST1250 | 1250 | 12 | 4.5 | 4 | ||

| ST1600 | 1600 | 12 | 5 | 4 | ||

| ST2000 | 2000 | 12 | 6 | 4 | ||

| ST2500 | 2500 | 15 | 7.2 | 5 | ||

| ST3150 | 3150 | 15 | 8.1 | 5.5 | ||

| ST3500 | 3500 | 15 | 8.6 | 6 | ||

| ST4000 | 4000 | 15 | 8.9 | 6.5 | ||

| ST4500 | 4500 | 16 | 9.7 | 7 | ||

| ST5000 | 5000 | 17 | 10.9 | 7.5 | ||

| ST5400 | 5400 | 17 | 11.3 | 8 | ||

| ST6300 | 6300 | 19.5 | 12.8 | 10 | ||

| ST7000 | 7000 | 19.5 | 13.5 | 10 | ||

| ST7500 | 7500 | 21 | 15 | 10 |

Note: Cover thickness, cord diameter, and cord pitch can be manufactured according to customer’s requirements.

Cover Grades

In accordance with HG/T 4224-2011 standard

| Grade | Tensile strength min. (ISO37) Mpa | Elongation at break (ISO37) % | Abrasion max. (ISO4649) mm³ | Change of tensile strength and elongation at break after hot air aging % |

| H | 25 | 450 | 120 | -25 ~ +25 |

| D | 18 | 400 | 90 | -25 ~ +25 |

| L | 20 | 400 | 150 | -25 ~ +25 |

| 1.Ozone resistant test condition: (50±5)pphm, 40±2℃, elongation: (20±2)%, time 96hours. 2.Hot air aging test condition:70℃×168h | ||||

The standard values in the table above help to select the appropriate covering adhesive for practical use. The reliable evaluation of the wear and cutting resistance of the covering adhesive cannot be determined by the tensile strength, elongation and wear alone.