- Inleiding

Inleiding

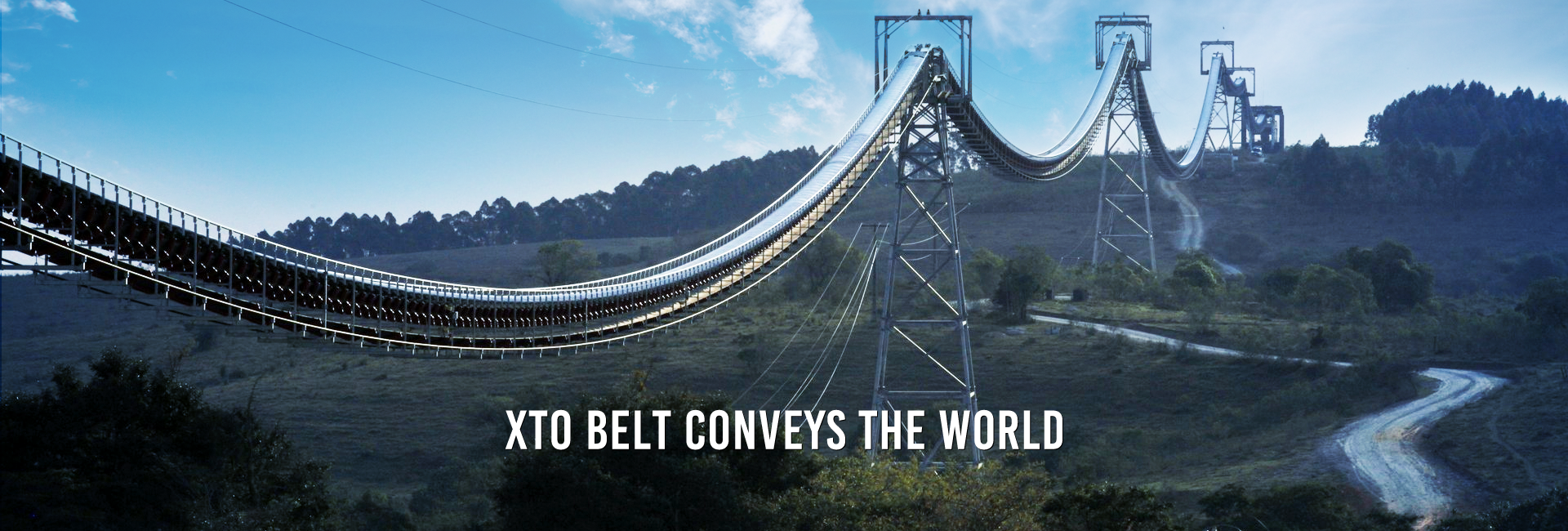

Gebruik

Het is geschikt voor langafstandstransport van bulkmaterialen, gebruikt in mijnen, havens, elektriciteitscentrales, metaalindustrie, chemische industrieën, steenkoolmijnen, etc.

Kenmerken

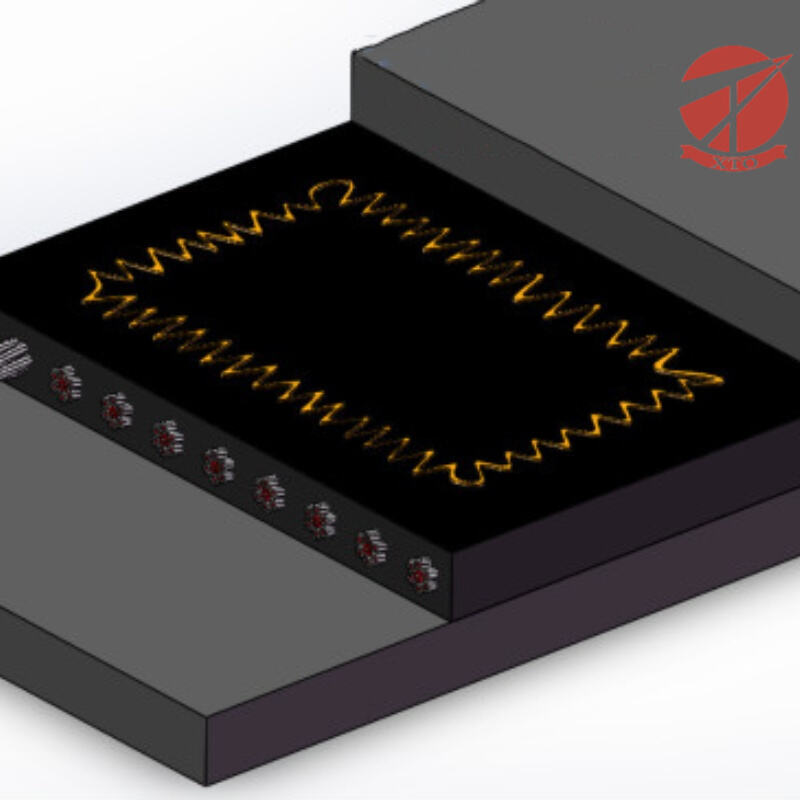

1. Wanneer een lopende band wordt gelast en de in de band ingebedde sensorlus beschadigd is, inclusief dat de band gescheurd is, zal het signaalcontrolesysteem de machine automatisch uitzetten en de alarmbel laten rinkelen, zodat de mate van scheuring van de band tot een minimum wordt beperkt.

2. Wanneer de transportband tijdens het lopen afwijkt, overschrijdt de afstand tussen de in de band ingebedde sensorlus en de sensor de ingestelde waarde, zal het signaalcontrolesysteem de machine automatisch uitzetten en de alarmbel laten rinkelen.

3. Wanneer de materialen vastlopen, detecteert de sensor de abnormale looptoestand van de band, waarna het signaalcontrolesysteem de machine automatisch uitzet en de alarmbel laat rinkelen.

4. De werkstatus van de conveyerbelt kan via het netwerk op elk moment en overal worden bewaakt.

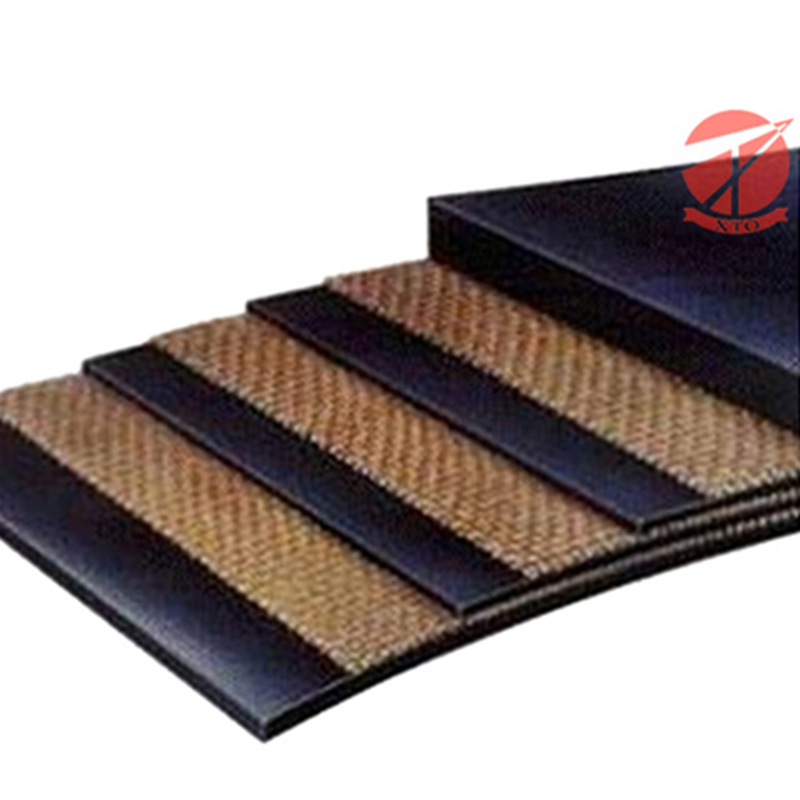

Standaard specificaties

| Model | Trekdraagkracht (N/mm) | Draadpitch (mm) | Draaddiameter (mm) | Minimale bedekkingstdikte (mm) | Breedte (mm) |

| ST630 | 630 | 10 | 3 | 4 | 800-2400 |

| ST800 | 800 | 10 | 3.5 | 4 | |

| ST1000 | 1000 | 12 | 4 | 4 | |

| ST1250 | 1250 | 12 | 4.5 | 4 | |

| ST1600 | 1600 | 12 | 5 | 4 | |

| ST2000 | 2000 | 12 | 6 | 4 | |

| ST2500 | 2500 | 15 | 7.2 | 5 | |

| ST3150 | 3150 | 15 | 8.1 | 5.5 | |

| ST3500 | 3500 | 15 | 8.6 | 6 | |

| ST4000 | 4000 | 15 | 8.9 | 6.5 | |

| ST4500 | 4500 | 16 | 9.7 | 7 | |

| ST5000 | 5000 | 17 | 10.9 | 7.5 | |

| ST5400 | 5400 | 17 | 11.3 | 8 | |

| ST6300 | 6300 | 19.5 | 12.8 | 10 | |

| ST7000 | 7000 | 19.5 | 13.5 | 10 | |

| ST7500 | 7500 | 21 | 15 | 10 |

Opmerking: De dikte van de cover, de diameter van de kabel en de kabelpitch kunnen volgens de eisen van de klant worden vervaardigd.

Cover Grades

| Kwaliteit | Trekspanning (ISO37) Mpa | Uitrekking bij breuk min. (ISO37) % | Slijtage max. (ISO4649) mm³ |

| H | 24 | 450 | 120 |

| D | 18 | 400 | 100 |

| XTO D | 18 | 400 | 50 |

De waarden zullen helpen om het juiste covermateriaal voor de toepassing of voor de te vervoeren materialen te bepalen. Een betrouwbare beoordeling van het gedrag van de covers in gebruik voor slijtage- en snijweerstand kan niet alleen op basis van trekspanning en slijtagecijfers worden bepaald.