Many different environments feature hoge temperatuur transportband, from food processing to mining to packaging. But why is this kind of belting so vital? One major reason is it can withstand extremely high heat. That means it can be used in machines that heat up to very high temperatures during their work without melting or degrading. This is an important feature because many machines need to get hot in order for them to work.

There’s help available, but it’s important to know that not all high temperature belts are equal. From one factory to the next and one business to the next, the needs would change which means finding the right kind of belt for your job is very important. Some belts, for instance, are made for food processing and others for mining work. A belt with the right properties can boost machine performance significantly.

There are a variety of aspects that you must consider when selecting a high temperature belt. They have to evaluate the amount of heat that the belt will be exposed to, how it will respond to various chemicals, and how much friction it can endure over time. You should also consider what type of machine you will be using the belt on, to ensure it will fit properly. A good fit a must to keep everything functioning smoothly.

Not only are high temperature belts robust, but they can also be used to help machines operate further efficiently. 39674When you install the appropriate belt, your machine can continue running without a hitch. This translates to less downtime so the factory can manufacture more products. Higher profits are good for business, and that is why increased productivity is a good thing.

A different method for ensuring that all goes smoothly is to select a belt with a low friction coefficient. Low friction means the machine doesn’t need to work as hard to move, conserving energy. This energy-efficient feature will not only work to reduce costs, but will also minimize wear and tear on the machine itself and on the belt. Using more efficient belts ultimately saves businesses money over time.

When it comes to grueling applications like extreme heat, high humidity and exposure to challenging chemicals, high temperature belts are designed for the job. The best materials are specifically designed and constructed in order to withstand the harsh environments without degrading. This is highly crucial as many industries deal with tough conditions on a daily basis.

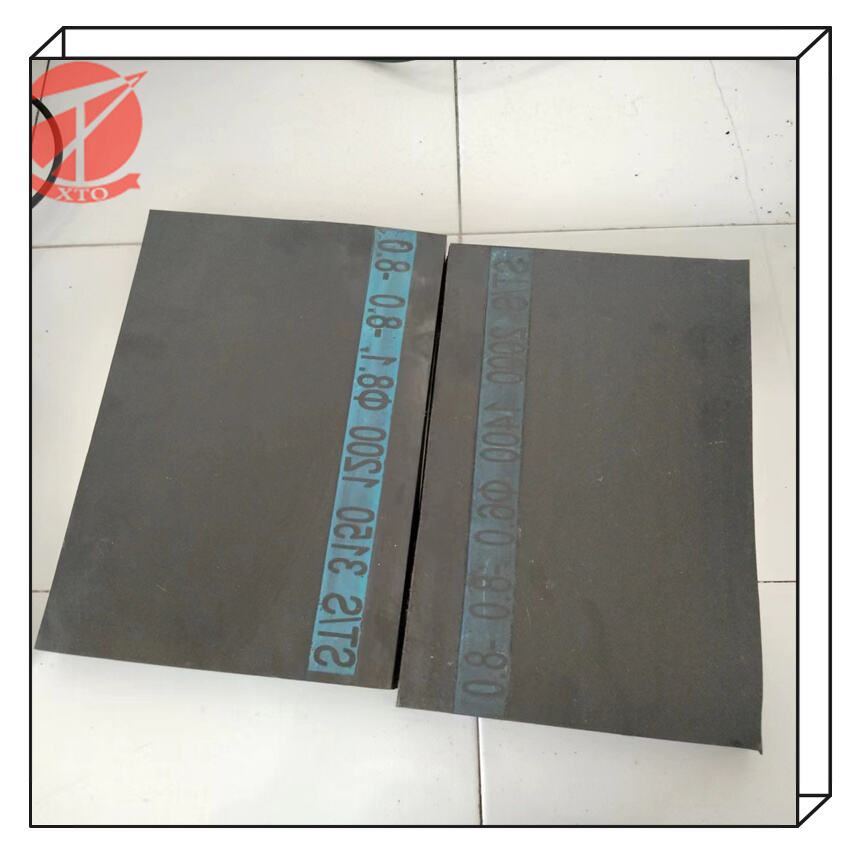

Replacing the thin rubber with high temperature belts such as silicone or fiberglass. These materials can handle heat well beyond 500°F! Besides being able to withstand extreme heat, they also resist chemicals that could break down other types of belts. They also have a low coefficient of friction, so they won’t jam or slide around while in use. This reliability is crucial for keeping machines up and running.

Our RD team comprises experts who are responsible for setting standards for national use We have 32 national utility models patents for example the "multi-ply fabric conveyor belt" and declared 3 invention patents and 11 utility model patents for example like an ultra-wear resistant conveyor belt Our company has formed partnerships with universities to show its leadership position in rubber technology We also have an extensive and efficient after-service team made up of high temperature belting

ISO9001, ISO14001, and ISO45001 are high temperature belting standards that we have been able to pass. And our products have repeatedly passed the quality testing conducted by renowned organizations like RWE, TUV, BV, MSHA and MASC.

The product line includes conveyor belts made of steel, multi-ply textile belt, solid woven conveyor belt and sidewall belts, pipe belts, patterned belt, lifting belt and aramid conveyor belt. The annual design capacity of 29 million square meters of conveyor belts. Among the belts: We have 11 conveyor belts that are solid woven production lines, four multi-ply textile belt production lines, and seven conveyor belts produced by steel lines. We also have the longest steel conveyor belt vulcanization machine cold in high temperature belting.

PVG conveyer belts are the biggest market share in China. The company has the latest production equipment as well as a skilled management team. We are vice-chairman of high temperature belting and is one of its leading makers. Our company has received awards such as "China Quality Brand" and "The Most Popular Brand in the Industry of Conveyor Belts in China", etc.