- Pengenalan

Pengenalan

Penggunaan

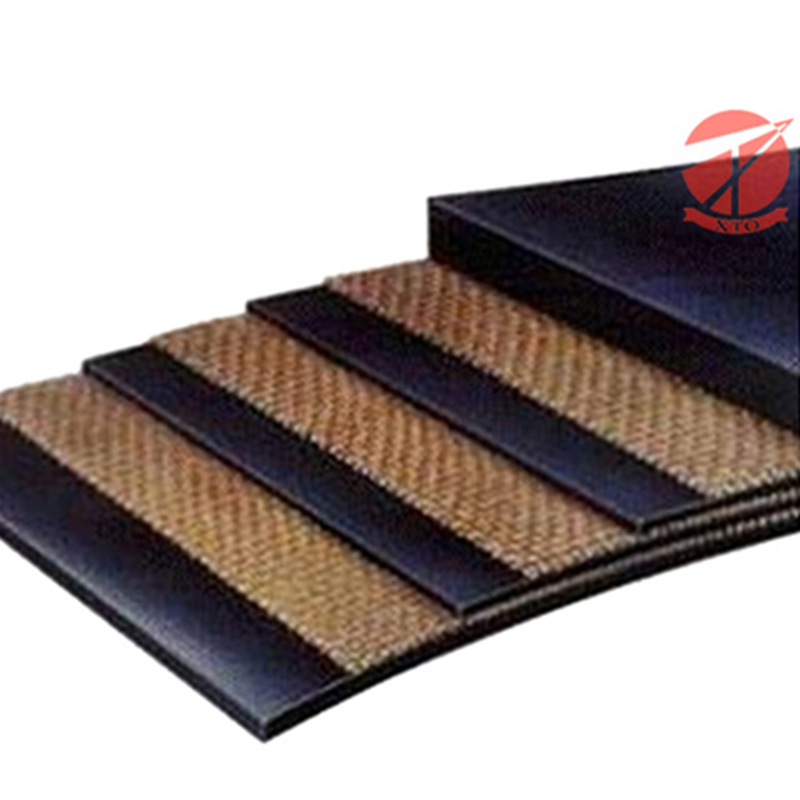

Belt konveyor talian keluli tahan asid-basa sesuai untuk mengangkut bahan-bahan dengan sifat kerosakan kimia di kilang-kilang kimia, kilang baja kimia, kilang kertas, industri tambang, dan sebagainya.

Ciri-ciri

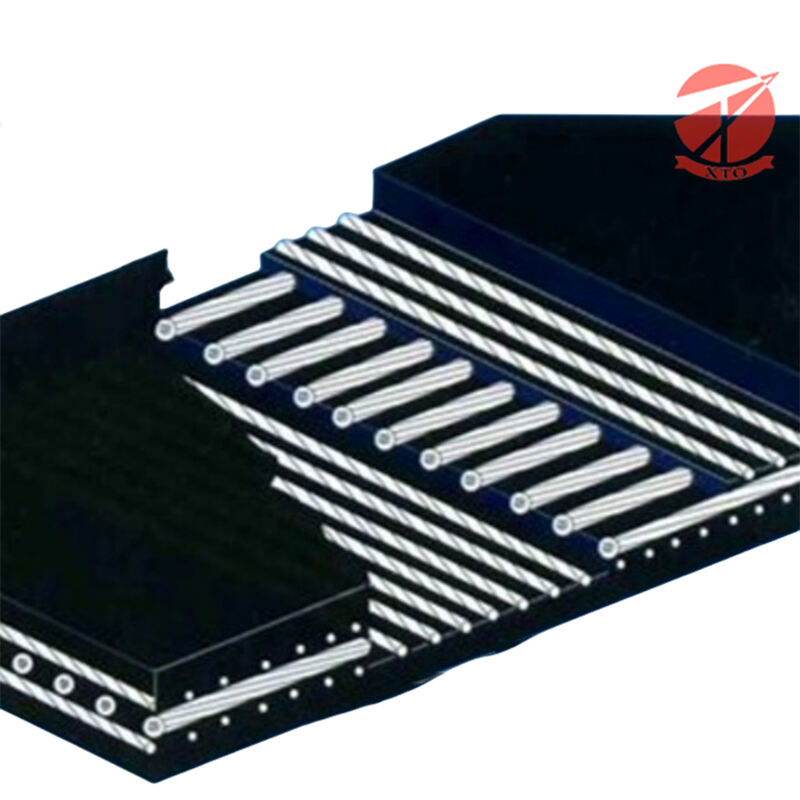

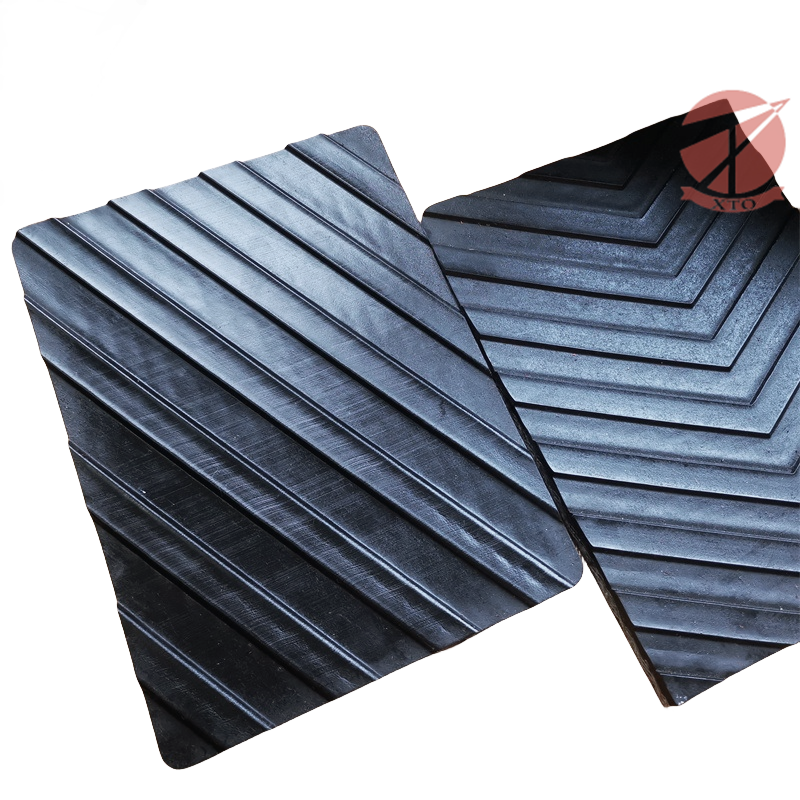

Dengan memilih keluli tali sebagai kerangka, tali ini mempunyai keupayaan yang baik dan keterlurusan yang cemerlang. Kover karet, yang dibuat daripada bahan tahan asid-bas, mempunyai ketahanan kimia yang hebat dan sifat fizikal yang baik.

Spesifikasi Standard

| Model | Kekuatan regangan (N/mm) | Pitch Tali (mm) | Diameter Tali (mm) | Ketebalan Minima Pelindung (mm) | Lebar (mm) |

| ST630 | 630 | 10 | 3 | 4 | 800-2400 |

| ST800 | 800 | 10 | 3.5 | 4 | |

| ST1000 | 1000 | 12 | 4 | 4 | |

| ST1250 | 1250 | 12 | 4.5 | 4 | |

| ST1600 | 1600 | 12 | 5 | 4 | |

| ST2000 | 2000 | 12 | 6 | 4 | |

| ST2500 | 2500 | 15 | 7.2 | 5 | |

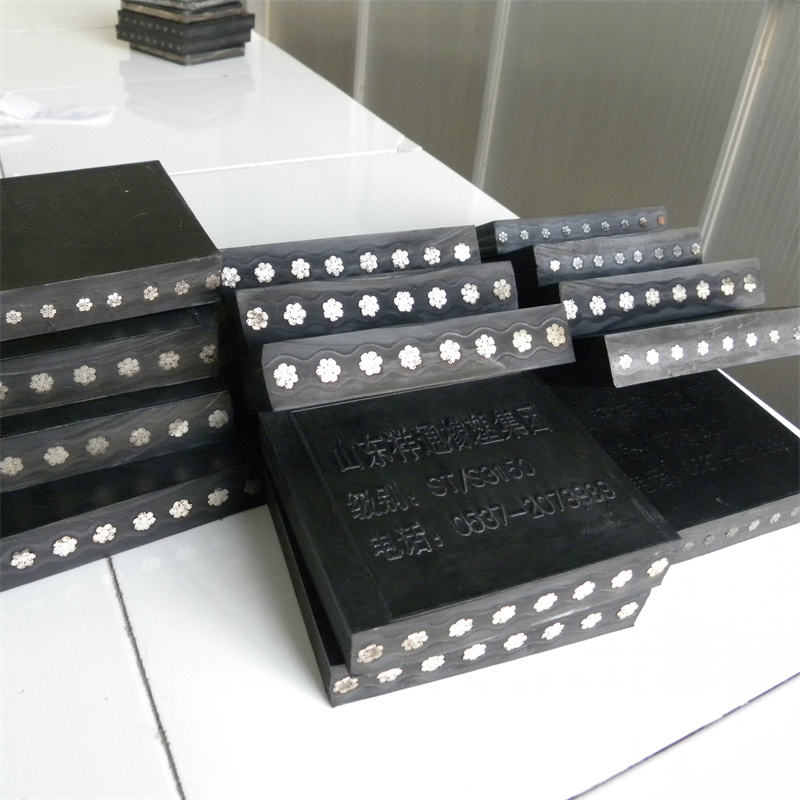

| ST3150 | 3150 | 15 | 8.1 | 5.5 | |

| ST3500 | 3500 | 15 | 8.6 | 6 | |

| ST4000 | 4000 | 15 | 8.9 | 6.5 | |

| ST4500 | 4500 | 16 | 9.7 | 7 | |

| ST5000 | 5000 | 17 | 10.9 | 7.5 | |

| ST5400 | 5400 | 17 | 11.3 | 8 | |

| ST6300 | 6300 | 19.5 | 12.8 | 10 | |

| ST7000 | 7000 | 19.5 | 13.5 | 10 | |

| ST7500 | 7500 | 21 | 15 | 10 |

Nota: Ketebalan penutup, diameter tali, dan pitch tali boleh dikeluarkan mengikut permintaan pelanggan.

Sifat Penutup

| Barangan | Kekuatan tarikan Mpa | Pemanjangan dan Patah % | Kenisan mm³ | Kerasness A⁰ | Pengaromakan Ozone | ||

| Ciri-ciri Fizikal | ≥14.0 | ≥400 | ≥250 | 55-70 | Tiada cerun | ||

| Penutup | Tahan asid dan alkali | Kelas | Cecair Rendaman | Ketumpatan | Keadaan Rendaman ℃×h | Kadar perubahan sebelum dan selepas direndam | |

| Kadar pembengkakan | Kadar perubahan kekuatan tarik | ||||||

| A1 | HCL | 18% | 50℃×96h | <+10% | <-10% | ||

| A2 | H2SO4 | 50% | 50℃×96h | <+10% | <-10% | ||

| A3 | NaOH | 48% | 50℃×96h | <+10% | <-10% | ||