Csapdás ipari szállítócsövesek minden szükségedre: A Shandong Xiangtong Gumi Tudomány területén tudjuk, hogy az ipari szállítócsövesek sok vállalkozás sikeres működéséhez alapvetően fontosak. Szállítócsövesek: Ezek segítségével mozgatni lehet különféle anyagokat egy helyről a másikra, amely gyorsabban teszi lehetővé a munkavégzést. De ha valami hiba történik ezekkel a csövesekkel, drága és időigényes lehet a javítás. Ezért most el szeretnénk osztani néhány egyszerű tippet ahhoz, hogy ilyen problémák elkerülhetőek legyenek. Ezeknek a tippjeinknek a követésével a szállítócsövesed jól fenntartott lesz, és minden simán fog futni.

Tipppek a súrlódás és feszültség javításához

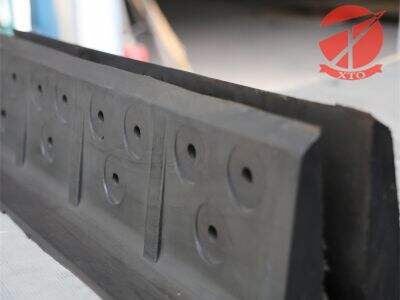

Egy túl alacsony súrlódás egy gyakori probléma a szállítócsövesekkel, éppúgy mint a(z) széttörés elleni acélkordú szállítócsöves A súrlódás az, ami megakadályozza a anyagok mozdulását a szalagon, hogy ne csúszzanak vagy nem mennek ámás. Káros lehet (különösen ha túl kevés a súrlódás), és időigényes (különösen ha túl sok a súrlódás). A szalag és gördülékek rendszeres ellenőrzése veszélyeztetésre vonatkozóan fontos jobb súrlódás érdekében. Ha a részek kihasználtak, problémákhoz vezethetnek, ezért figyelni kell őket.

Megfeszítheted a szalagot, hogy többet ragadjon. A feszültség azt mutatja, mennyire csendes a szalag. Túl széles, és a szalag csúszik; túl feszült, és kockázat van, hogy megrágad. Tehát, meg kell találni a helyes egyensúlyt. Figyelni kell, hogy ne túl feszüljön a szalag, hiszen könnyen elképzelhető, hogy minden alkalommal, amikor ezt teszed, felesleges terheket és károkat okozol, és végül rosszabb lesz.

Tisztítási módszerek a szallaghordozó tisztaságához

A szállítócsövesek tipikus problémája a szennyezés, a por és a szemét felhalmozódása. Amikor ez bekövetkezik, a csővét kevésbé hasznosnak teheti, de néhány esetben teljesen megállíthatja a működését. Ajánlott rendszeresen tisztítani a csövet, hogy ezt elkerülje. Tisztítható speciális szállítócsöves gyapjúval vagy speciális szállítócsöves tisztítóttermékekkel.

Győződjön meg arról, hogy olvassa el és kövesse a gyártó biztonsági szabályait és utasításait a tisztítás során. A tisztítás kulcsfontosságú karbantartási lépés, tehát folytassa rendszeresen annak érdekében, hogy a csővét problémamentesen futtassa. Emellett segíteni fog megakadályozni az váratlan meghibásodásokat, amelyek késleltethetik a munkát.

Egyszerű módszerek a csővét egyenesen tartásához

Ha például egy szállítócsőv ilyen bányászó szállítóvízszintes nem igazodik, elhelyezkedhet helytelenül. Ez pedig azért lehet probléma, mert a szalag korábban kihasználódik, növelve az összehúzásokat és a termelési leállásokat. Ennek megelőzésére pár egyszerű szokás fejlesztésével járhat, például rögzített időközönként ellenőrizze a szalagot annak biztosítása érdekében, hogy egyenes és helyén van. Így hát mielőtt bármilyen parancssoros varázslatot alkalmazna, egy egyszerű vizuális ellenőrzés sok bajt menthet el később.

Érdemes befektetni érzékelőkbe és más figyelőeszközökbe is. Ezek az eszközök lehetővé teszik a korai beavatkozást, hogy az elhelyezkedés hibája vagy más potenciális akadályok felfedezésére legyenek olyankor, amikor még nem nagyobb gátak váltottak. Tehát, legyen proaktív, ellenőrizze rendszeresen, és küzdje meg ezeket a kisebb problémákat, mielőtt nagyokká válnának.

A meghibásodások gyors javítása

Még akkor is, ha gondosan kezelte a szállítószalag berendezés jól és figyelmen kívül hagyja az összes karbantartási tanácsot, a meghibásodások lehetségesek. Fontos megszüntetni a leállást és a költségeket a lehető leggyorsabban, amikor meghibásodás bekövetkezik. Minél hosszabb idő alatt nem működik a szalag, annál nagyobb a hatása a vállalkozásodon.

Módok a meghibásodás javítására: Szorítsa meg a szivárványt, Cserélje ki a meghibásodott részt, Ha szükséges, szabályozza a szalag feszültségét. Gyors és hatékony reakció a problémára, és kisebb lesz a hatása a műveleteidre a meghibásodás miatt. A gyors válaszok időt és pénzt takarnak meg – emlékezz erre.

Ez a típusú program célja a mozgás hibáinak kijavítása a teljesítmény javítása érdekében.

Végül, bármilyen anyagmozgás a szalagra kell beszélni. A problémák körétől kezdve záporos mozgásokon, túlzott zajig, a szalag rossz nyomásig terjedhet. Ezek a problémák módosíthatják a szalagfutó oldali teljesítményét, és ha nem helyezik helyre, további komplikációkhoz vezethetnek.

Javítsd ezeket a problémákat annak érdekében, hogy mihamarabb látszol őket, és nagyobb teljesítményt érhet el a szállítócsövetszerüggyel. Nemcsak egyszerűbbé teszi a munkát, hanem útmutatást ad arra, hogyan kerüljön el a jövőbeni meghibásodásokat és problémákat.

Shandong Xiangtong Gumi Tudomány: Meg fogunk küzdeni azért, hogy segítsük vásárlóinkat a legjobb teljesítményre és a leghosszabb élettartamra a csövesüket illetően. Ezekkel a legjobb gyakorlati tanácsokkal és rendszeres karbantartással a csövetszerüggyed hálásan fut, és sok közismert problémát elkerülhetsz. Kérlek, bátran fordulj a csapatunkhoz segítségért bármilyen kérdés esetén a szállítócsövetszerüggyel kapcsolatban. Hiszünk magunkba, és mindig ott vagyunk neked, hogy biztosítsuk, hogy műveleteid jobban és simábban haladjanak.