- Esittely

Esittely

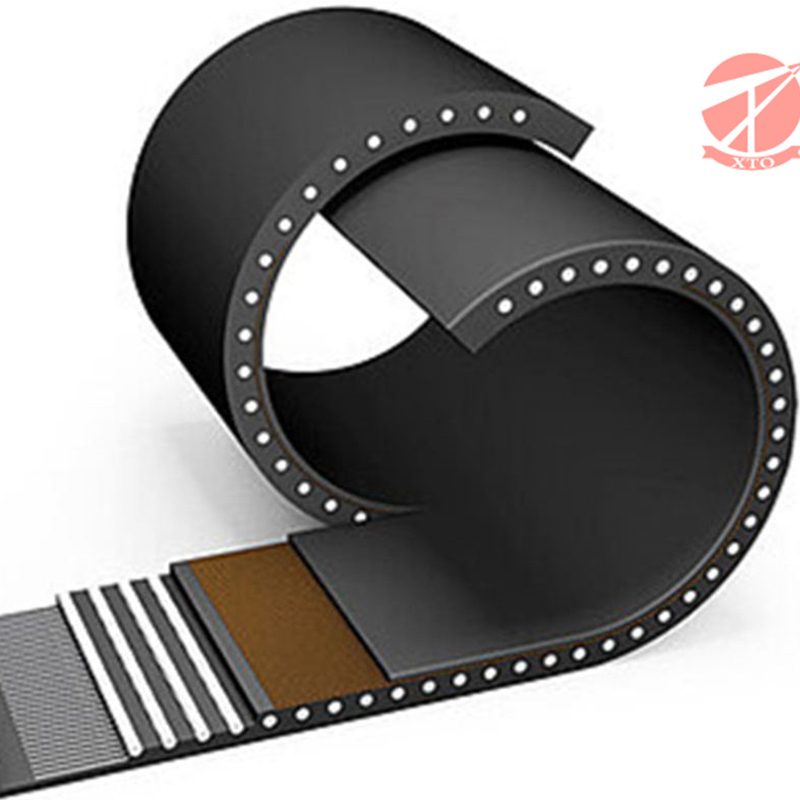

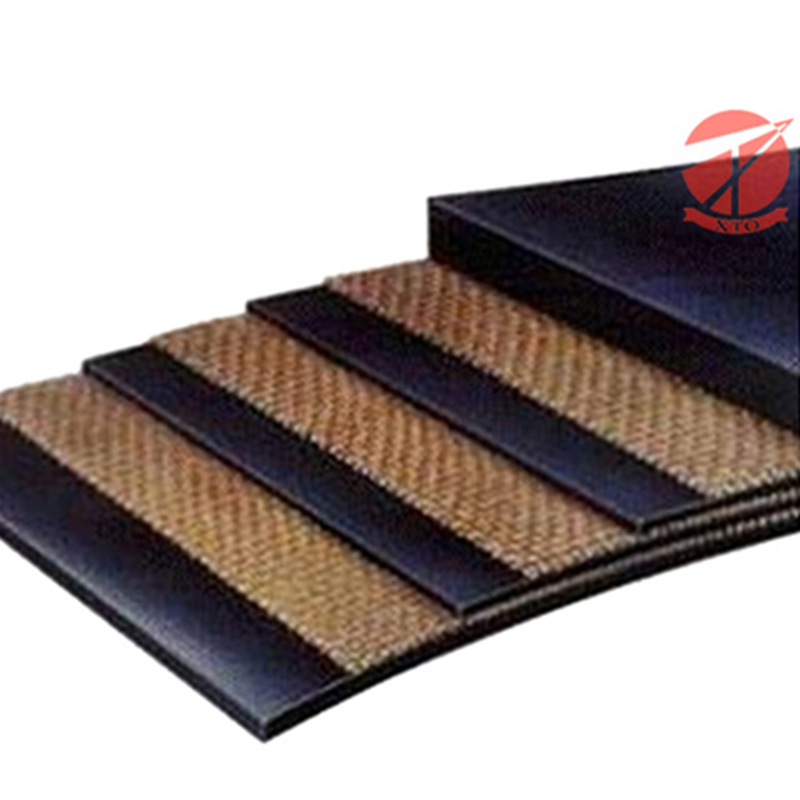

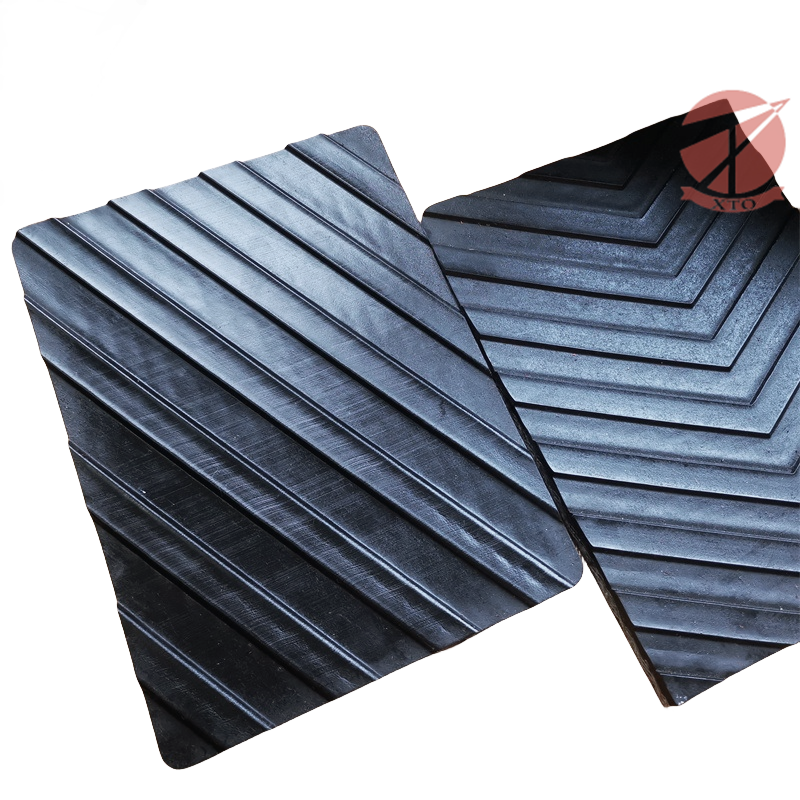

Käyttö

Putketeräsliittymäkonveerikangas on uusi kuljetustuote, joka koostuu teräsliitännäisistä ytimenä ja korkean joustavuuden, korkean kaulatusvastuksen ja korkean vahvuuden kauchukusta työpinnänä. Sen käytetään pääasiassa hienojen, granuloitujen ja muiden materiaalien kuljettamiseen, jotka saastuttavat ympäristöä helposti. Kun se toimii, nauha muuttuu vähitellen tasosta U-muotoiseksi ja lopulta putkemuotoiseksi, mikä peittää aineksia ja toteuttaa suljetun kuljetuksen.

Ominaisuudet

1. Huoltokustannusten ja siivouskustannusten vähentäminen materiaalin häviämisen ja menetyksen välttämiseksi konveerillä

2. Kuljetettavan aineksen suoja ulkoisten vaikutusten, kuten pylyn, sadon tai tuulen, vastustamisesta

3.Ympäristön suojelu saastumiselta siirrettävän materiaalin vuoksi

4.Suuri kulma siirtotuloksessa, siirtokulma on yleensä enintään 30 astetta;

Tekniset tiedot

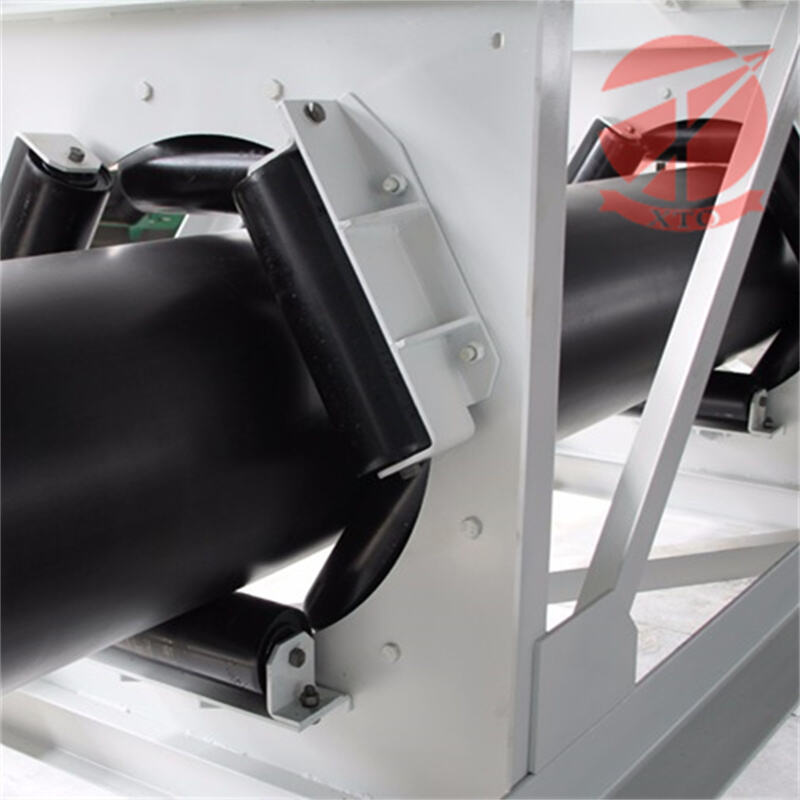

1.Pyhvälaukku voidaan ohjata läpi tiukat vaakasuorat ja pystysuorat käyriät, koska se tuetaan kuudesta kiertolohkosta. Tämä johtaa siirtopisteiden vähentämiseen ja parempaan sopeutumiseen olemassa olevaan maastoon tai tehdasrakennuksiin.

2.Korkeammat kaltevuuskulmat voidaan saavuttaa, koska pyhvin sisäpuoli tarjoaa enemmän konttityötä siirrettävälle materiaalille verrattuna säännölliseen siirtopyhviin.

Vakiotiedot

| Malli | Venymärajoitus (N/mm) | Korven pituus (mm) | Korven halkaisija (mm) | Pienin peitepaksuus (mm) | Leveys (mm) | Putken halkaisijat (mm) |

| ST630 | 630 | 10 | 3 | 4 | 800-2400 | 100 150 200 250 300 350 400 450 500 550 600 |

| ST800 | 800 | 10 | 3.5 | 4 | ||

| ST1000 | 1000 | 12 | 4 | 4 | ||

| ST1250 | 1250 | 12 | 4.5 | 4 | ||

| ST1600 | 1600 | 12 | 5 | 4 | ||

| ST2000 | 2000 | 12 | 6 | 4 | ||

| ST2500 | 2500 | 15 | 7.2 | 5 | ||

| ST3150 | 3150 | 15 | 8.1 | 5.5 | ||

| ST3500 | 3500 | 15 | 8.6 | 6 | ||

| ST4000 | 4000 | 15 | 8.9 | 6.5 | ||

| ST4500 | 4500 | 16 | 9.7 | 7 | ||

| ST5000 | 5000 | 17 | 10.9 | 7.5 | ||

| ST5400 | 5400 | 17 | 11.3 | 8 | ||

| ST6300 | 6300 | 19.5 | 12.8 | 10 | ||

| ST7000 | 7000 | 19.5 | 13.5 | 10 | ||

| ST7500 | 7500 | 21 | 15 | 10 |

Huomautus: Peiteen paksuus, kaapin halkaisija ja kaapin askel voidaan valmistaa asiakkaan vaatimusten mukaisesti.

Peiteasteet

Noudattaen HG/T 4224-2011 -standarta

| Arvosana | Vetojännitys vähintään (ISO37) Mpa | Pituusmuutos rikkoutumisessa (ISO37) % | Kaukaisuus enintään (ISO4649) mm³ | Muutos vetovoimassa ja rikkoutumisjännitteessä ilmapiirin ikuisuuden jälkeen % |

| K | 25 | 450 | 120 | -25 ~ +25 |

| W | 18 | 400 | 90 | -25 ~ +25 |

| L | 20 | 400 | 150 | -25 ~ +25 |

| 1. Ozoonikestävyyskokeen ehdot: (50±5) pphm, 40±2℃, venymä: (20±2)%, aika 96 tuntia. 2. Ilmapiirin ikuisuuskokeen ehdot: 70℃×168h | ||||

Yllä olevan taulukon standardiarvot auttavat sopivan peittokleejan valitsemisessa käytännön käytössä. Peittokleejan kestovaurio- ja leikkausvastuksen luotettava arviointi ei voi määritellä pelkästään vetovoiman, pituusmuutoksen ja kuljetuksen perusteella.