- Cyflwyniad

Cyflwyniad

Defnydd

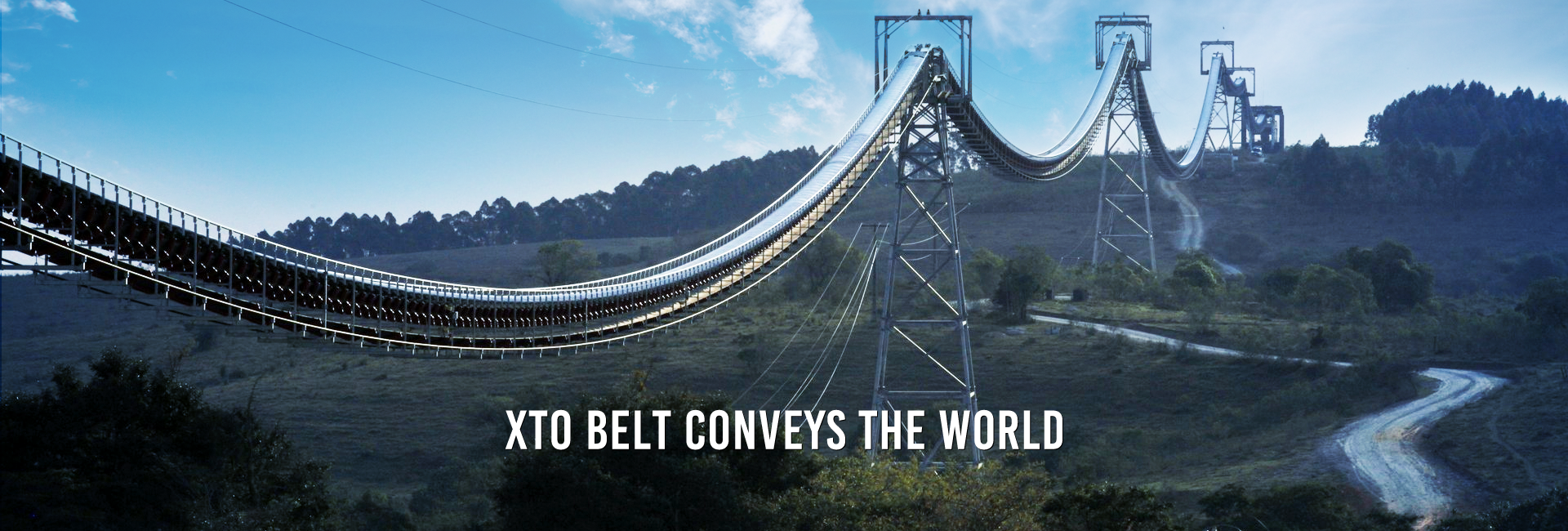

Mae beirniadau llwybr ambiwlans yn addas ar gyfer trefnu deunyddion gyda drwydded uchel, pellter hir, a lwc cyfrifol iawn, ac maent yn cael eu defnyddio'n sylweddol yn y gweithgynlligoedd glo, mynyddoedd, portiau, metalwriaeth, wydr, diwydiannau, ac fathau eraill.

Nodweddion

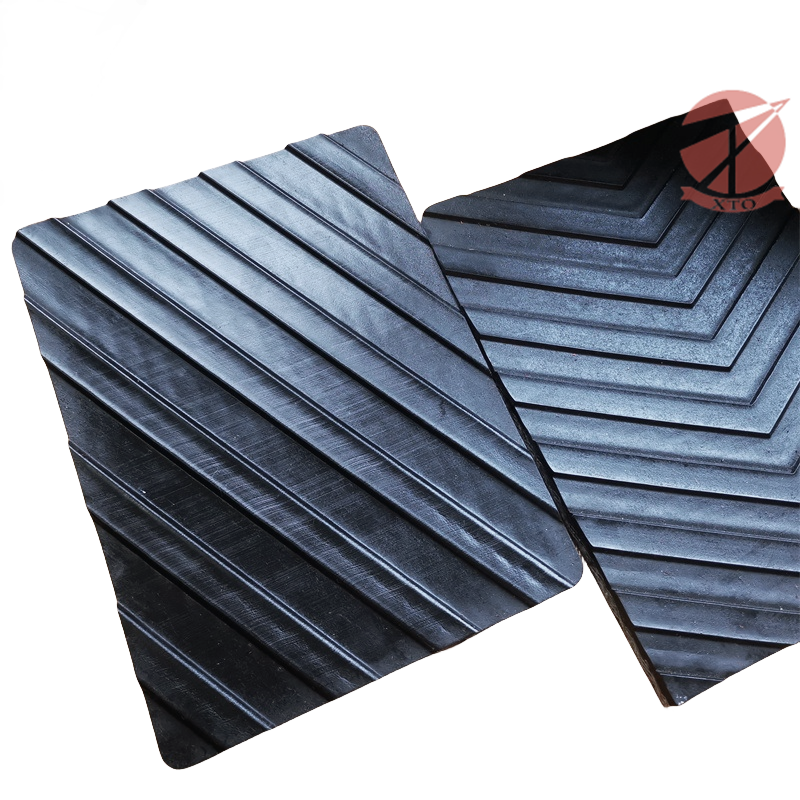

1. Gwneudder amrywiadol uchel: Mae'r cintynau yn addas ar gyfer cyfrannu materion dros fesurau mawr, llawer o bell.

2. Llediad bach wrth ei ddefnyddio: Mae angen dimensiwn llai i'r cintynau i gymryd eu lle.

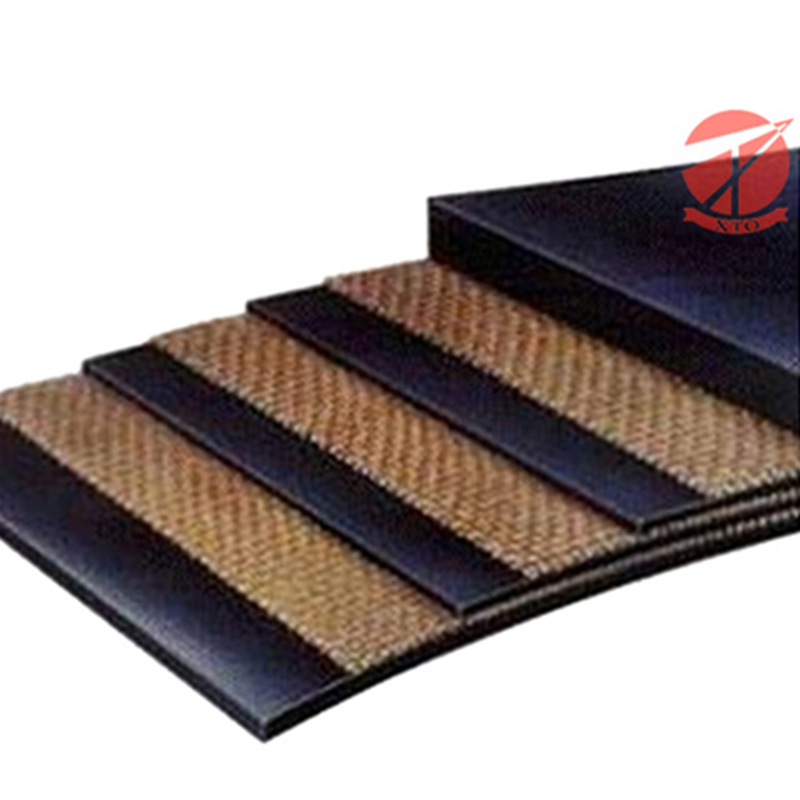

3. Diametr bach i'r pullydd drys: Mae'r corff yn cynnwys lygad o ffyrciau ariannol yn cais fel ei sgrin, ac felly mae'n ddirwynt i llosgi. Oherwydd hynny, gall pullydd bachach i'w defnyddio er mwyn gwneud y dylun llai.

4. Llawdriniaeth uchel rhwng symud a lliw fêr: Mae'r lliwau âern yn cau â sylen ar eu wynebau, a hefyd mae'r lliw sy'n cael ei ddefnyddio gyda phriodoledd da o gysylltiad â'r lliwau âern. Felly, mae'r lliw yn bwrw yn agos i'r lliwau âern ac yn dirmyg i sgythu a anodd erioed i'w golli, felly mae'r bendoedd lliw yn hir amser yn gweithio.

5. Tensïon cyfartalog o'r lliwau âern: O ran ein technegau uwch yn y cynhyrchu, mae'r lliwau âern yn cael eu trefnu'n gyffredinol ac yn cael tensïon cyfartalog, felly mae'r bendoedd yn barhau'n dda a anodd iddyn nhw allforio.

6. Daioniad da: Gan nad oes gan yr elusen unrhyw sclafodd llawer, mae'n hawdd i'w gynrychioli fel troedfa gwyllt, felly gall y bendoedd llwytho mwy o deuluoedd a diwallu'r teuluoedd o ddod allan.

7. Gwirio'r bendigedig gyda rai X: Gall defnyddwyr gymryd raiau X i wirio am danïadau ar y lliwau âern yn y mynediwnau i atal digwyddiadau.

Fersiynau Safonol

| Model | Pryder Llygad (N/mm) | Gyfnod Cord (mm) | Diametr Cord (mm) | Cyffredinol Lled Hyd (mm) | Lled (mm) |

| ST630 | 630 | 10 | 3 | 4 | 800-2400 |

| ST800 | 800 | 10 | 3.5 | 4 | |

| ST1000 | 1000 | 12 | 4 | 4 | |

| ST1250 | 1250 | 12 | 4.5 | 4 | |

| ST1600 | 1600 | 12 | 5 | 4 | |

| ST2000 | 2000 | 12 | 6 | 4 | |

| ST2500 | 2500 | 15 | 7.2 | 5 | |

| ST3150 | 3150 | 15 | 8.1 | 5.5 | |

| ST3500 | 3500 | 15 | 8.6 | 6 | |

| ST4000 | 4000 | 15 | 8.9 | 6.5 | |

| ST4500 | 4500 | 16 | 9.7 | 7 | |

| ST5000 | 5000 | 17 | 10.9 | 7.5 | |

| ST5400 | 5400 | 17 | 11.3 | 8 | |

| ST6300 | 6300 | 19.5 | 12.8 | 10 | |

| ST7000 | 7000 | 19.5 | 13.5 | 10 | |

| ST7500 | 7500 | 21 | 15 | 10 |

Nod: Dybedrwydd y gwrthdrawf, diamiad y sêl, a phich y sêl gall fod yn cau yn ôl gofynion y cleifion.

Ardalau Llyfru

| Gradd | Pryder Tensyl (ISO37) Mpa | Lledaenu i frwydro leiaf (ISO37) % | Gwarediad mwyaf (ISO4649) mm³ |

| H | 24 | 450 | 120 |

| D | 18 | 400 | 100 |

| XTO D | 18 | 400 | 50 |

Bydd y gwerthoedd yn helpu i ddatrys y cymysgedd golwg addas ar gyfer yr apwyntiad neu ar gyfer y materion sy'n cael eu gwneud. Ni all asesiad dderbyniol o ymddygiad y golau yn y gwasanaeth am gymhareb i wleidyddiaeth a chynnyg ei ddod o reolaeth tensiwn, a thrigiadau gwarediad yn unig.