- Úvod

Úvod

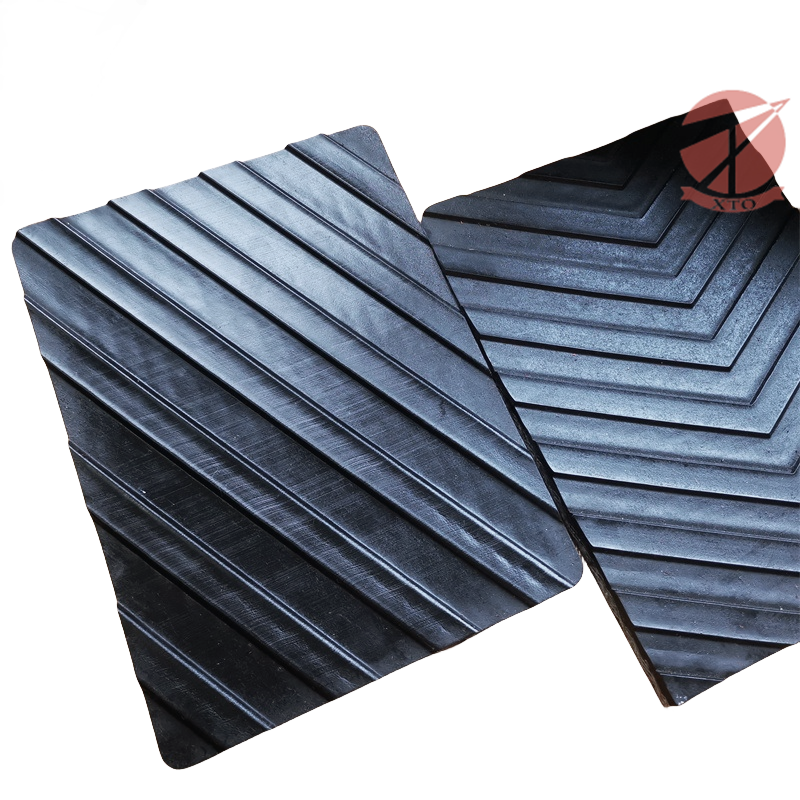

Použití

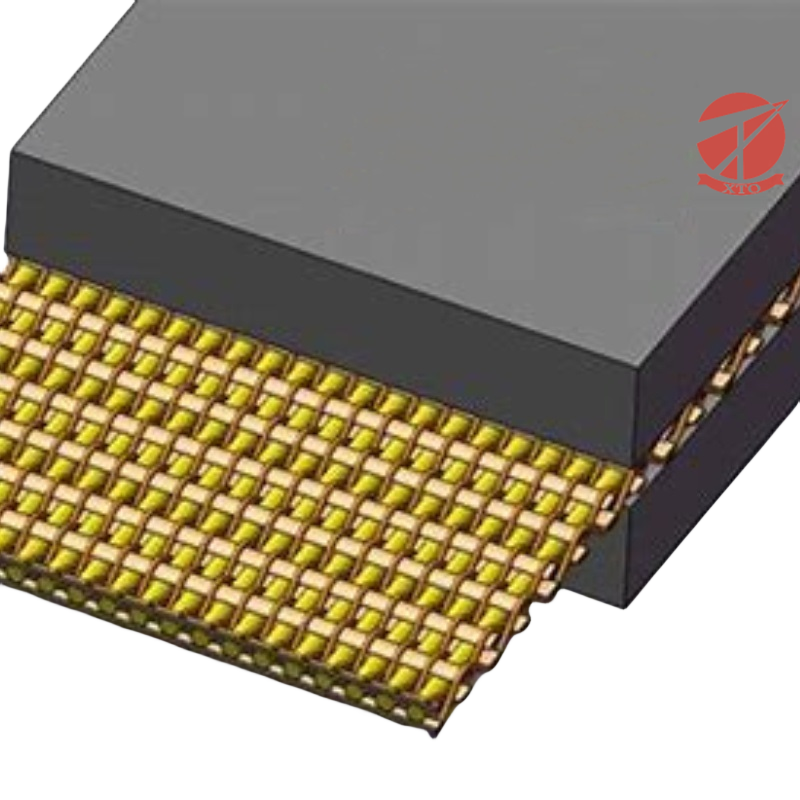

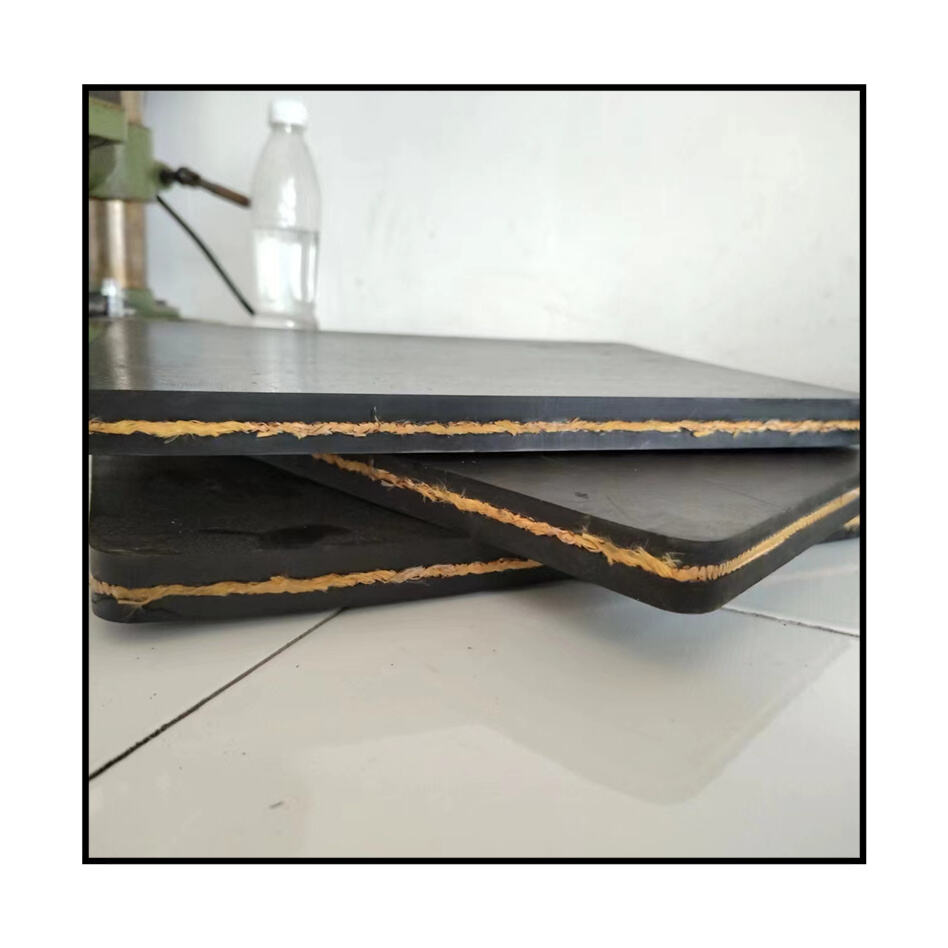

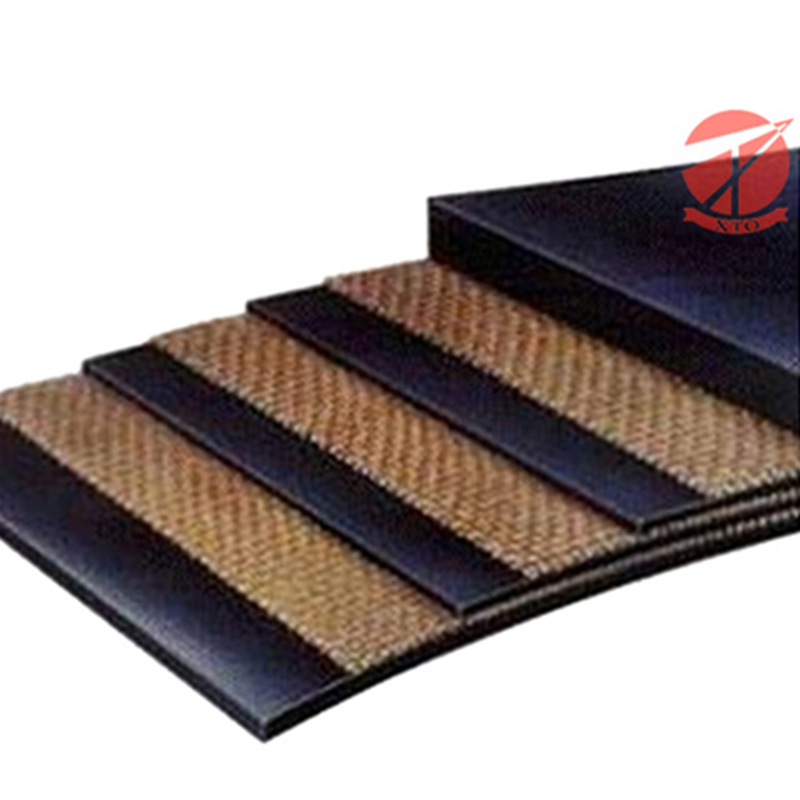

Nosná struktura je vyrobená z vysokopevnostní aramidu a nylonu 66 s rovnými vlákny. Tato konstrukce je charakterizována vysokým stupeňem zachování pevnosti a délky plátna.

Dlouhá a malá (<0,5 %) odolnost proti bočnímu dopadu je dobrá, takže není třeba přidávat síť proti trhnutí. Aromatické kolové plátno převaděcí pásové je vhodné pro systém přepravy s vysokou pevností, dlouhou vzdáleností a velkým objemem. S nátěrem odolným proti opěku, teplu, ohni nebo plamenu může být přizpůsobeno řadě významných podmínek.

Vlastnosti

1. Nízké spotřebování energie: Struktura s rovnými pružinami a rovnými vlnami se skládá z aramidových vláken v průběhu a nylonových vláken v plstech na obou stranách, které chrání pás. Sníží to spotřebu energie převaděče. Ušetří více energie použitím úsporného guma s nízkým odporom při valení jako pulzní strana.

2. Odolnost proti dopadům: Díky výdrži aramidové látky může chránit převaděcí pás před probodnutím ostrými dopravními materiály. Dokonce i v případě velké vzdálenosti klesání sníží poškození převaděcího pásu.

3. Vysoká odolnost proti teplu a plamenům: Vlastnost vysoké odolnosti proti teplu chrání převaděcí pás před poškozením vysokoteplotními dopravními materiály. Dokonce i hořící látky nejsou snadno schopny proniknout do aramidového jádra.

4. Odpornost na korozi: Aramid, jako umělá tkanina, má samotná vynikající odolnost proti médiu. Navíc má vynikající vlastnosti chemické odolnosti a odolnosti proti korozi.

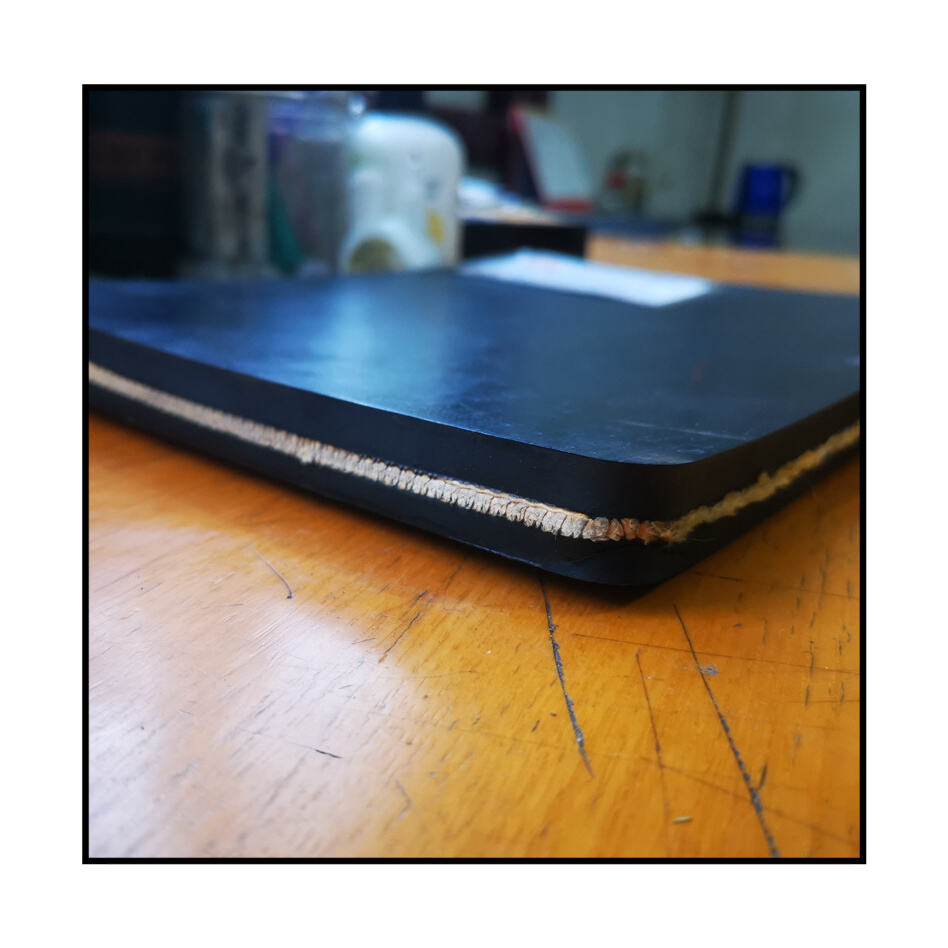

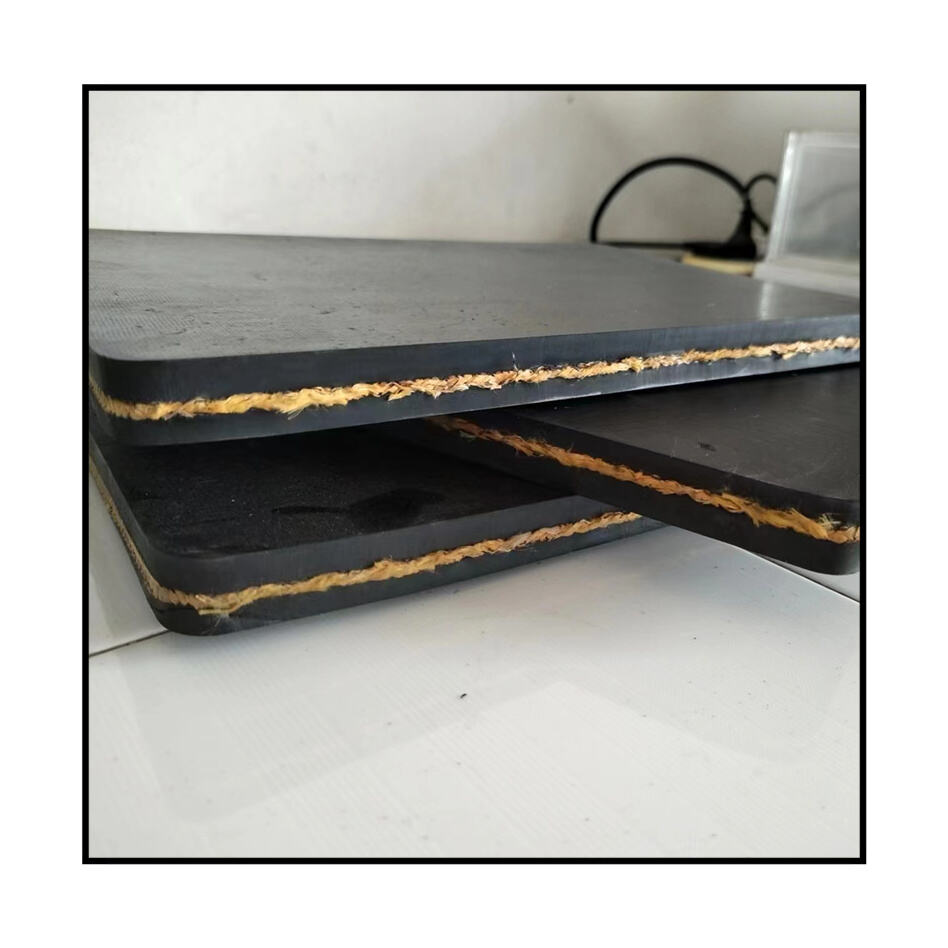

5.Optimalizovaný design pásu pro dlouhý život: Protože je pouze jedna textilní vrstva, je nosná struktura lehká a pružná s optimálním využitím síly. Aramidové převaděcí pásmo je během celého života vynikající ve snesení unavení. Horní a spodní obložení vyhovuje vysokým požadavkům na odolnost proti opotřebení a dopadům, což poskytuje optimální ochranu pro cenný aramid.

Standardní specifikace

| Specifikace | Tahová síla N/mm | Prodlužovací pevnost % | Rated Elongation of 10& | Textilní měrka | Měrka obložení | Šířka | ||

| Obal≥ | Výplň≥ | Obal≥ | ≤ | mm | NAVRHU | Spodní část | 500-2400 | |

| DPP630 | 630 | 120 | 5 | 0.5 | 2.1 | 6-25 | 5-15 | |

| DPP800 | 800 | 150 | 2.2 | |||||

| DPP1000 | 1000 | 150 | 2.4 | |||||

| DPP1250 | 1250 | 150 | 2.7 | |||||

| DPP1400 | 1400 | 150 | 2.8 | |||||

| DPP1600 | 1600 | 150 | 2.9 | |||||

| DPP1800 | 1800 | 150 | 3.2 | |||||

| DPP2000 | 2000 | 150 | 3.6 | |||||

| DPP2500 | 2500 | 150 | 4 | |||||

| DPP3150 | 3150 | 150 | 4.3 | |||||

Kvality obalu

| Třída | Pevnost na trhnutí (ISO37) Mpa | Průběžné prodlužování minimálně (ISO37) % | Obrat maximálně (ISO4649) mm³ |

| H | 24 | 450 | 120 |

| H | 18 | 400 | 100 |

| XTO D | 18 | 400 | 50 |

Tyto hodnoty pomohou určit vhodnou směs obalu pro použití nebo přepravované materiály. Spolehlivá posouzení chování obalů v provozu ohledně odporu proti nosnosti a řezu nemůže být stanovena pouze na základě pevnosti na trhnutí a hodnot obratu.