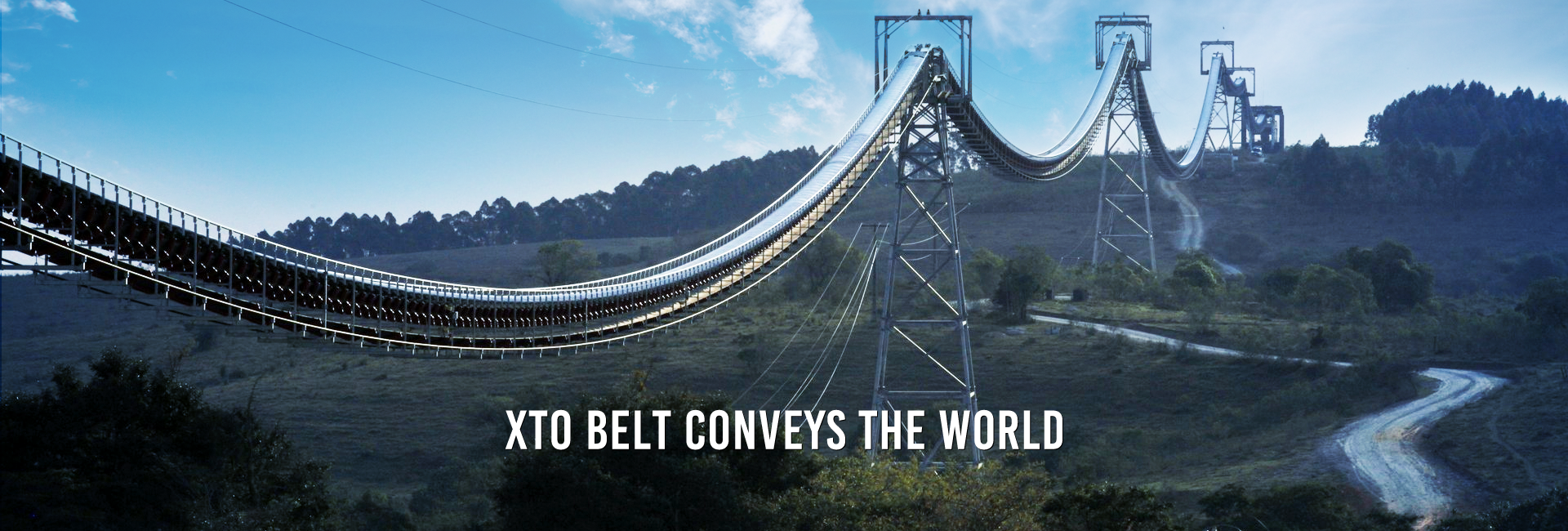

- Introduction

Introduction

Usage

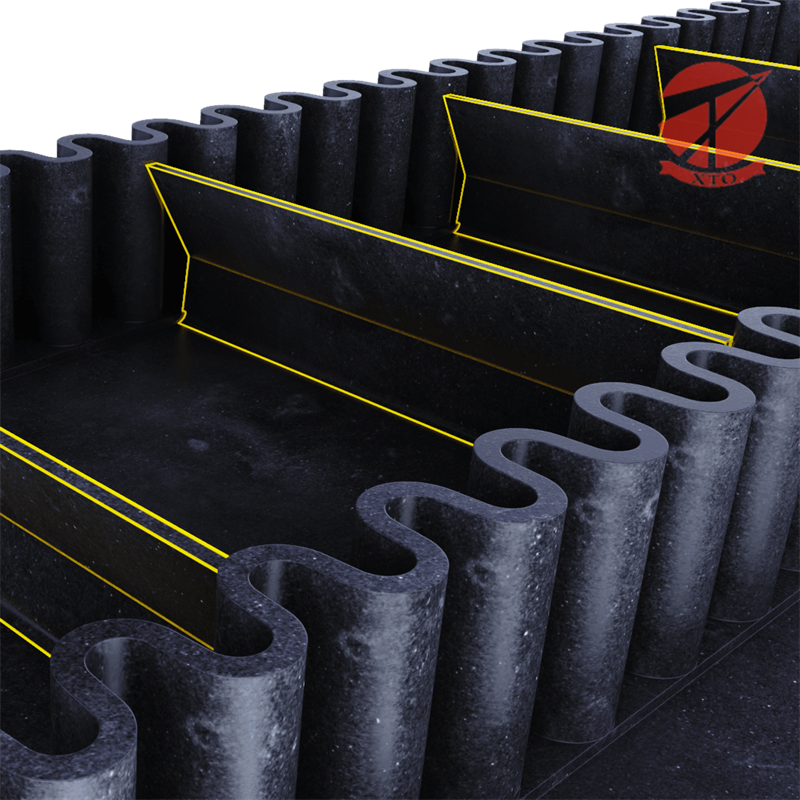

In order to prevent the conveying materials scattering due to site restrictions or the requirement for lifting materials with large dip angel, the sidewall conveyor belt must be able to withstand the extremely high stress and repeated flexing that occurs in high capacity, steep angle conveying.This is the use of high modulus, very low shrinkage polyester fabric to provide higher stiffness values.This product is suitable for conveying materials under the condition of large dip angle (0°-90°).

Characteristics

1.Materials can be conveyed at a large slope up to 90°.

2.The belt has large loading capacity and the materials won’t be scattered.

3.The slope of conveying can be changed from horizontal to sloping, or from sloping to horizontal.

4.The conveyor is simple in structure, flexible in arrangement and occupying only a small area.

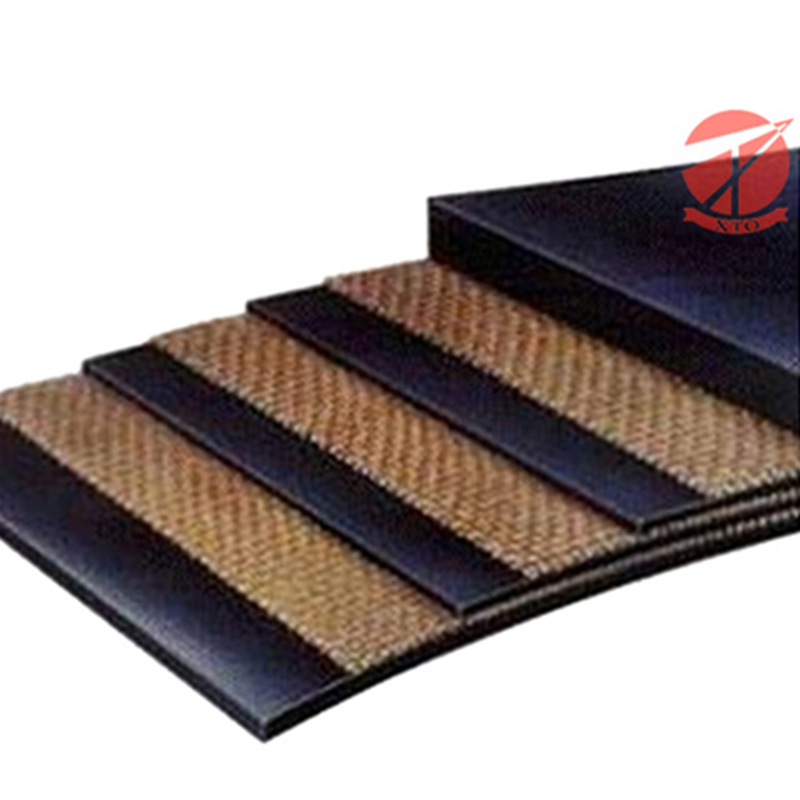

Standard Specifications

| Strength(KN/m) | No. Of Piles | Carcass Type | Belt Width |

| 300 | 2-4 | NN/EP | 500-2400mm |

| 400 | 2-4 | NN/EP | |

| 500 | 2-5 | NN/EP | |

| 630 | 3-6 | NN/EP | |

| 800 | 3-6 | NN/EP | |

| 1000 | 3-6 | NN/EP | |

| 1250 | 3-6 | NN/EP | |

| 1400 | 3-6 | NN/EP | |

| 1600 | 4-6 | NN/EP | |

| 2000 | 4-6 | NN/EP |

Note: It can be customized according to customers’ requirements.

Sidewall Specifications

The sidewalls are moulded in a high quality rubber.

| Type | Square Ratio | Weight(kgs) | Bottom width |

| S60 | 0.75 | 2.5 | 50 |

| S80 | 0.82 | 3.53 | 50 |

| S100 | 1.42 | 4.18 | 50 |

| S120 | 1.69 | 4.53 | 50 |

| S160 | 2.68 | 8 | 75 |

| S200 | 3.53 | 9.5 | 75 |

| S240 | 5.15 | 12.5 | 75 |

| ES300 | 7.52 | 11 | 100 |

| ES400 | 10.67 | 14.5 | 100 |

| ES500 | 13.82 | 17.6 |

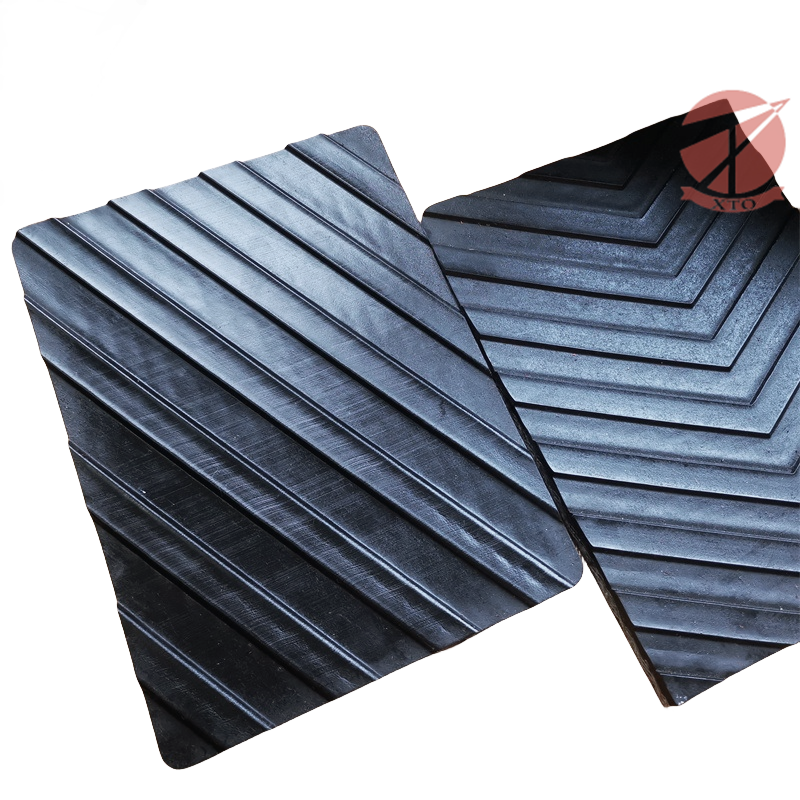

Cleat Specifications

The cleat is made of high quality rubber, having high elasticity on the supporting effect.

| Type | Square Ratio | Weight(kgs) |

| TC55 | 0.72 | 1.05 |

| TC75 | 0.81 | 1.2 |

| TC90 | 1.34 | 2 |

| TC110 | 1.76 | 2.3 |

| TC140 | 2.36 | 3.43 |

| TC180 | 3.13 | 4.52 |

| TC220 | 5.63 | 5.8 |

| TC280 | 10.7 | 8.6 |

| TCS360 | 14.45 | 13.6 |

| TCS470 | 28.9 |

Cover Grades

| Grade | Tensile strength min. (ISO37) Mpa | Elongation at break min. (ISO37) % | Abrasion max. (ISO4649) mm³ |

| H | 24 | 450 | 120 |

| D | 18 | 400 | 100 |

| L | 15 | 350 | 200 |