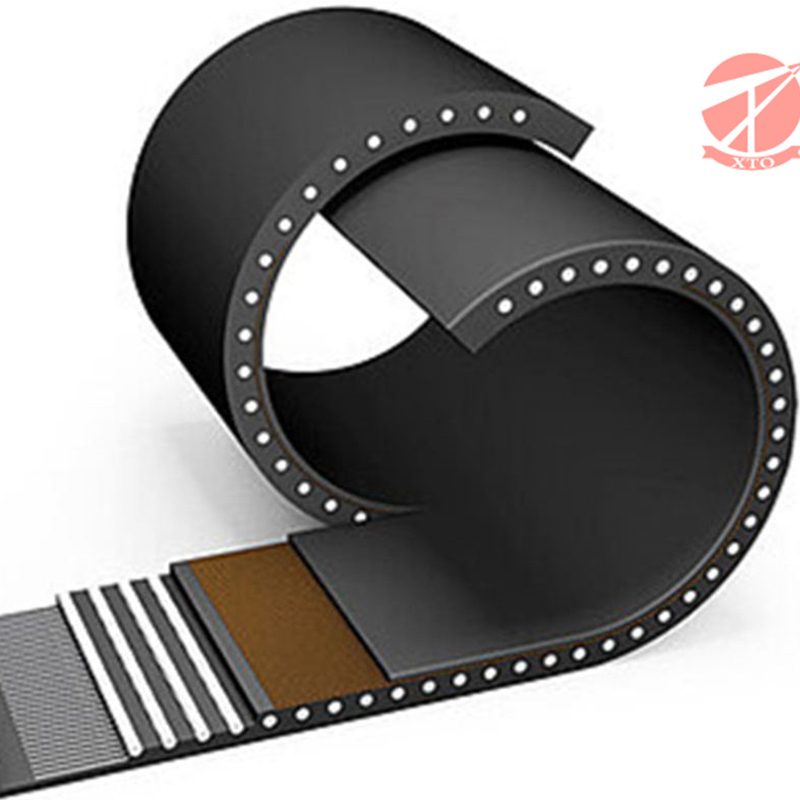

THE IRREPLACEABLE ELEMENT OF THE INDUSTRIAL WORLD - STEEL CORD CONVEYOR BELTS

Steel cord conveyor belts are used in the industrial sector through which heavy materials can be easily pass over any possible distance. That said, not all steel cord conveyor belts are created equal. But in this article, we are going to consider steel cord conveyor belts - their main features and most promising manufacturing companies that develop these best-in-the-class equipment.

Pros of Steel Cord Conveyor Belts

These belts are much stronger and long-lasting when compared to various other types of conveyor belt. Good tear, puncture and impact resistance = Excellent for high-volume users of sharp or abrasive material industries. In addition to this, these belts have low stretch properties so that they can effectively haul heavy loads at high speeds therefore making them a perfect candidate for material handling industries where the flow of element is fast.

Technology beginnings of steel cord conveyor belt Manufacturers

To meet the various demands of the industrial sectors, manufacturers are continually working to improve and develop steel cord conveyor belts design as well as performance. For example, leather firms that feature belts now offering greater flexind The aliove heavier stress without forsaking sturdiness. Some even incorporated redundant sensors and monitoring systems, alerting when the belts were in peril - improving safety while lowering operational costs.

Steel Cord Belt Safety Features

In any industrial environment, safety is the bottom line so conveyor belts are regarded as appropriate technological applications that help you bring food for everyone! Safety features such as fire resistance and antistatic properties are included by manufacturers to avoid the mishaps and reduce risks that could happen. Furthermore, there are also the belt edge detectors and rip detection systems from certain manufacturers that will indicate when a riddle has started so it can be addressed before it gets more threatening to workers.

How You Get Most Out of Steel Cord Conveyor Belts

Using and Maintaining Steel Cord Conveyor Belts effectively is the key to unlocking their benefits. Inspecting the goods for damage before installation is important. The tensioner for the belt, which should be placed and revisited there from time to time if necessary. In addition, systematic monitoring of the entire conveyor system is necessary to avoid malfunctions and accidents that can disrupt operations and create potential safety risks.

Standards for Service and Quality of Steel Cord Conveyor Belts

Choosing the right manufacturer of steel cord conveyor belts is important in order to ensure accuracy and industry norm adherencevinfos A decent manufacturer provides technical support, field services, warranties and guarantees to keep you satisfied. They even carry out the due diligence in order to maintain world class quality on their offerings.

Applications & Uses of Steel Cord Conveyor Belts

Applications of steel cord conveyor belts are common in industries like mining, constructions and transporting etc. They are very long and used to carry materials such as iron ore, coal, gravel etc. These are widely used in cement and steel processing plants due to high-temperature resistance properties, durability.

6 Largest Steel Cord Conveyor Belt Manufacturers

Then the six top steel cord conveyor belt manufacturers have unique products and services for all your abrasion challenges

ContiTech

Fenner Dunlop

Bridgestone

PHOENIX

Sempertrans

Trelleborg

Selecting the Steel Cord Conveyor Belt Manufacturing Right Manufacturer:The importanceA steel cord conveyor belt manufacturingof selecting a good sunder is important in ensuring that there are high levels of efficiency, safety and productivity maintained during industrial operations. Businesses can analyze benefits, innovations, protections and operational direction of steel cord conveyer belts for practical choices according to individual necessities on their uses.