If you have ever visited a plant, maybe you saw along the part where something that is like an extensive belt used to transport goods from one place on another. In short - conveyor belt. Working the conveyor belts around removing waste materials from a factory also many people I suppose don't realize it.

Most of the time, scraps are just waste material: small bits and pieces left over from doing some job or (in particular) machining. These are scraps left from producing and need to be taken away so there is enough space for new supplies in the manufacturing. And this is precisely where scrap conveyor belts come in to a great use and are needed.

As other conveyor belts, Scrap Conveyor Belt is specially composed to take away waste materials out of the production line. They assist in the cleaning process to ensure everyone is safe. When the scraps are collected through it, they will convey those to another side in which can be thrown or recycle. This makes it a lot quicker and easier than picking through the scraps with your fingers (which can be very time-consuming!)

Scrap Conveyor Belts If you think about factories, and why use scrap conveyor belts then it really comes down to keeping things clean. When the waste builds up too high, it can create problems that will halt production. The clean environment in the production area also means that all machines work at their optimum and consequently increase daily output of items.

Scrap conveyor belts may also be designed to work with other trash debris. For example, they take with us metal scrapes and plastic pieces etc., or other things also like sawdust. This versatility in waste disposal allows factories to stay operational and can save a business money on disposing of the byproducts their industry creates.

One, they can reduce the labour cost of cleaning out waste. So while conveyor belts are moving scraps automatically, workers do not waste their workforce on such process and they can concentrate elsewhere more important works that keep production running. This results in production being more convenient, and cost savings are done by the factory.

Also, Scrap conveyor belts can take waste right up recycling centers. This will not only reduce the costs of waste disposal but can also become a competitive advantage for the factory. Factories can both save money and not affect the landfills so much at all when they find savings materials like scrap material to be utilized into conveyor belts.

We have a highly skilled RD team with experts who are setting national standards. And we have obtained 32 national utility model patents like "multi-ply conveyor belt made of scrap conveyor belt" and has issued a total of 3 invention patents as well as 11 utility model patents such as ultra-wear resistant conveyor belt, and has partnered with a number of universities, which shows the company's leading position in rubber industry technology. We also have an extensive and efficient after-service team made up of 32 individuals.

PVG conveyer belts are the biggest market share in China. The company has the latest production equipment as well as a skilled management team. We are vice-chairman of scrap conveyor belt and is one of its leading makers. Our company has received awards such as "China Quality Brand" and "The Most Popular Brand in the Industry of Conveyor Belts in China", etc.

ISO9001, ISO14001 and ISO45001 are the three rigorous standards that we have been able to pass. Our products have also scrap conveyor belt successfully passed the quality tests conducted by renowned organizations such as RWE, TUV, BV, MSHA and MASC.

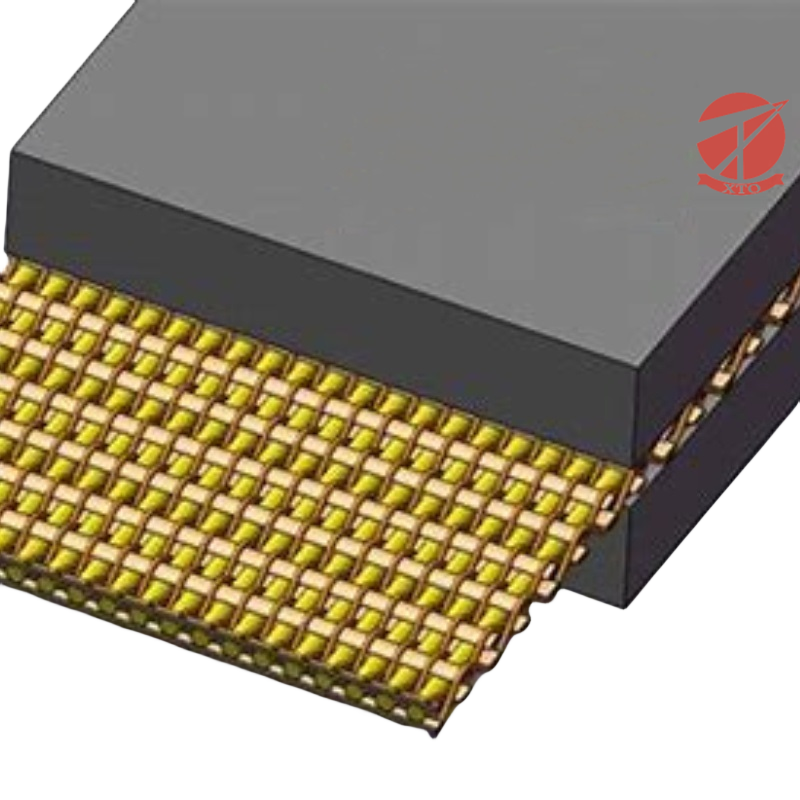

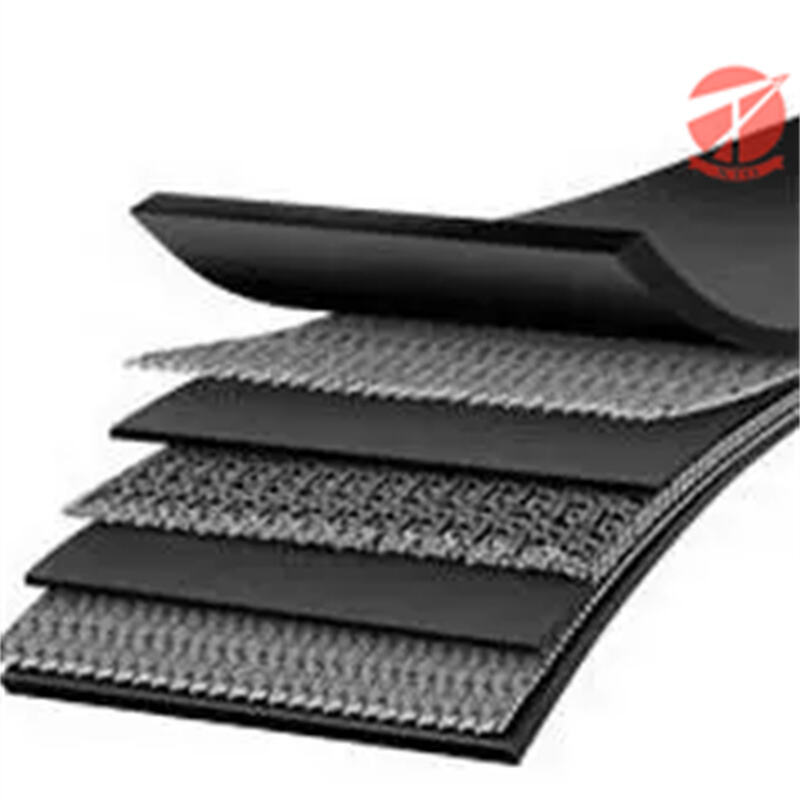

The scrap conveyor belt range covers steel cord conveyor belt as well as multi-ply fabric belts. the solid conveyor belt as well as sidewall belt, pipe belt, patterned belt, lifting belt, and an aramid conveyor belt. The annual design capacity of 29 million square meters of conveyor belts. Among them, we have 11 solid woven conveyor belt production lines, 4 multi-ply textile belt producing lines, and 7 conveyor belts made of steel lines. It also has the longest steel cold conveyor belt vulcanization equipment in Asia.