A conveyor belt is a long moving table that allows goods to be brought from one place to another. Maybe you saw one in your grocery store or at work in a factory. A conveyor belt in a factory that packages things, slides products from one machine to another. That way, the whole process goes a lot faster and it saves tons of time for their workers.

You have to carry each product by hand from the one machine to another. Doing that job would be exhausting and take hours But the products go by through a conveyor belt themselves! They generally work hands-free, so workers can finish other important jobs while the conveyor handle its duties by itself. This will speed up the packaging phase - and everyone gets their products faster.

The modern conveyor belts are made even better than the higgaldy piggeldys and claptraps of old. You can see why this is good in a busy factory as they are able to lift and carry heaps of things at once. This helps to let businesses preparation their merchandise rapidly, which is crucial in situations when a lot of individuals take them off the shelf. They have lots of customers so they need to package things as quickly as possible for everyone.

Now, let me discuss a neat little thing called automated conveyor technology. This is the new way of using conveyor belts which helps to save time. This means the belt line can instruct products where to be sent in order reach your machines. So the workers don't need to tell where should all these products are going each and everytime. The conveyor belt knows best!

However, products can be a variety of sizes and shapes so other automated conveyor technologies are used to sort the product based upon size or shape. Supply either crates of different sizes, for the conveyor to take them in place. This excels even further in that it leads to less mistakes hence perfecting the packaging as a whole. When packaging sorted product, customers receive what they expect as products are packed correctly.

Conveyor belts can also be used to reduce labor costs, as explained in the previous sentence. There are not as many workers required because so much of the work is done by the conveyor itself. This enables companies to conserve money that they can this invest in something else such as advancing their products or services.

To sum up, a packaging conveyor belt is also an indispensable tool that speeds up the operation while improving efficiency. It allows the workers achieve more can save cost on energy and better quality of product. This is a very secure method of transferring products from one machine to another, keeping everything within the original packaging.

The company boasts modern production equipment, professional management team, and top technology, so that the company has developed into a formidable competitive ability of the enterprise and the PVG conveyer belt holds the highest percentage of the packaging conveyor belt in China. We are vice-chairman in China's conveyor belt market and also one of the leading makers. The company was awarded the honor of "China Quality brand" and "The most important brand in the area of conveyor belt in China", etc.

packaging conveyor belt, ISO14001 and ISO45001 are the three strict standards we have successfully completed. Our products have also repeatedly passed the quality testing conducted by renowned companies like RWE, TUV, BV, MSHA and MASC.

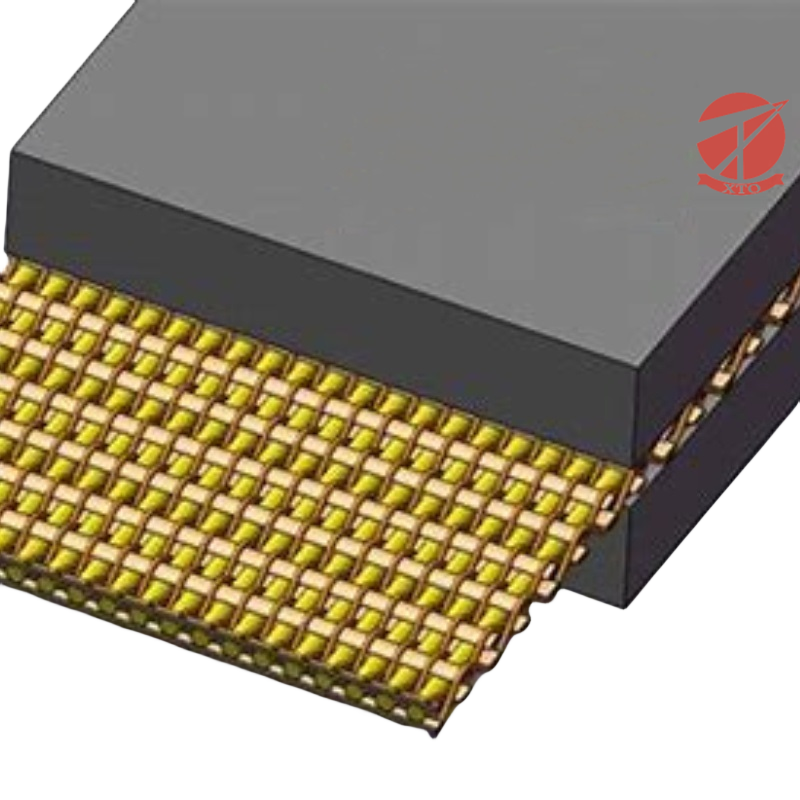

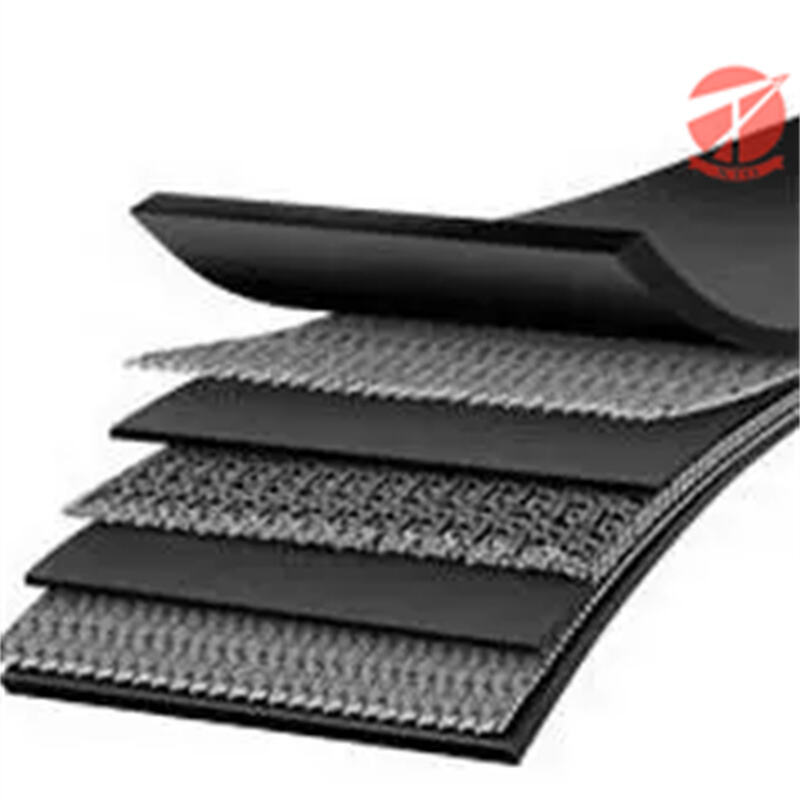

Our RD team is comprised of experts who are responsible for setting national standards. We have packaging conveyor belt national utility models patents for example, the "multi-ply fabric conveyor belt" and have declared three invention patents and 11 utility model Patents, such as an ultra-wear-resistant conveyor belt. The company has also joined forces with several universities to show its leadership position in rubber technology. We also have a large and reliable after-service staff made up of 32 people.

The packaging conveyor belt range covers steel cord conveyor belt as well as multi-ply fabric belts. the solid conveyor belt as well as sidewall belt, pipe belt, patterned belt, lifting belt, and an aramid conveyor belt. The annual design capacity of 29 million square meters of conveyor belts. Among them, we have 11 solid woven conveyor belt production lines, 4 multi-ply textile belt producing lines, and 7 conveyor belts made of steel lines. It also has the longest steel cold conveyor belt vulcanization equipment in Asia.