But do you know the companies that manufacture conveyor belts for mining in Russia? Conveyor belt suppliers are famous companies. The mining industry is vital to all industries as it uncovers precious materials like gold, coal, and other resources. This is exactly the kind of resources we consume in so many aspects of our lives every single day. In fact, they are essential in mining as conveyor belts help to move the materials easily and in shortest possible time from one place to another. Mining would be much more difficult without conveyor belts which allows to transport heavy items faster than manually possible.

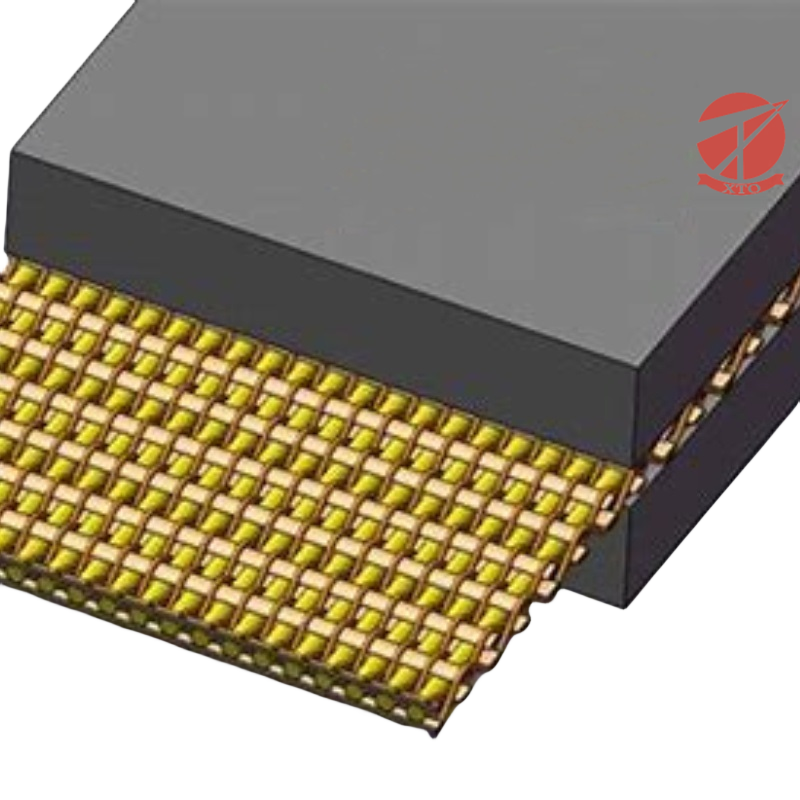

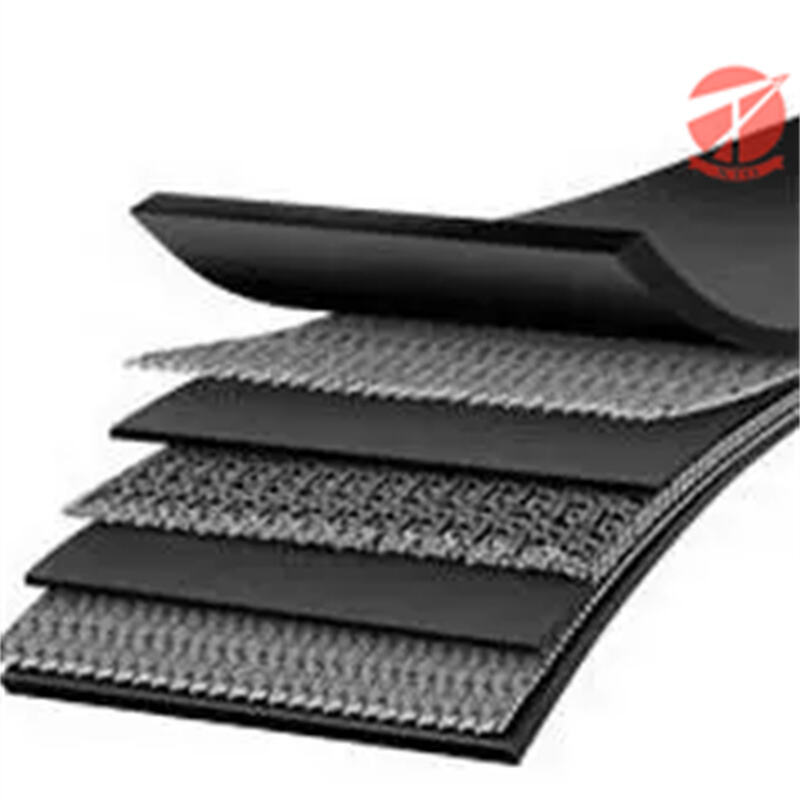

Conveyor belts for mining operations need to be strong and capable of holding large loads. The best conveyor belt suppliers have belts suited for the rugged conditions of mining. These materials include rubber, steel and fabric, so you can be sure that the belts will withstand all conditions. Therefore they are highly-durable and can withstand harsh conditions where other belts might snap. Durability 2 - It is important to have quality equipment in mining as it can be a tough job and the work should move on smoothly without any obstruction.

Mining companies must depend on reliable suppliers to provide them the conveyors that they require in their work. As these suppliers are required to supply on time and qualitative belts; any delay could create a problem in the mining process. It also provides expert advice from the suppliers should mining companies be unsure which belts would work best for their job. For a mining company, opting for the wrong belt can result in inefficiencies and additional expenditure so this support is absolutely key.

In mining, conveyor belts are essential as they aid to move large and bulky material quickly and efficiently. Transporting goods from one location to another would be a daunting task, without the use of conveyor belts. That is why mining companies must find methods to move the ore safely and efficiently from source to destination, known in our industry as conveyor belt solutions. Options such as a cleaner to prevent belts from becoming cluttered, belt managers that help keep the belts tight and in sync or unions that make it easy for various conveyors operating together-you need them all. Each of these elements are required to keep the entire system running well and productive.

The mining industry is hard and conveyor belts must be strong, durable. Heavy duty conveyor belts are largely utilized within the mining, aluminum and steel industries or inside plant construction sites wherever there might be far more injury towards belt from transport of increased products. They are made of tough materials that will be able to maintain being banged around, worn on jobs over time. They have also been designed to be easy to fit and service, an important advantage for the mining operations which use conveyor systems that must continually run with a minimum of costly downtime.

The same goes for different styles of mining operations, as not all mines are created equal when it comes to the type and miners need from conveyor systems. This is why many suppliers provide choice for customized conveyor belts. These belts may have an assortment of designs to fulfill the specific needs, for example they can be ordered by width and size or even type provides. Find out how for more of the content: The level of customisation is designed to result in each mining job with an optimal operational conveyor, translating into greater efficiency and productivity.

The company is equipped with the latest production equipment, a professional management team, as well as top technology to ensure that the company has developed into a mining conveyor belt suppliers competitive capability of the company and the PVG conveyor belt is the biggest percentage in the marketplace in China. We are vice-chairman of China's conveyor belt industry and is one of the most renowned makers. The company won the honor of "China Quality brand" as well as "The most important brand in the area of conveyor belt in China", etc.

The product line includes conveyor belts made of steel, multi-ply textile belt, solid woven conveyor belt and sidewall belts, pipe belts, patterned belt, lifting belt and aramid conveyor belt. The annual design capacity of 29 million square meters of conveyor belts. Among the belts: We have 11 conveyor belts that are solid woven production lines, four multi-ply textile belt production lines, and seven conveyor belts produced by steel lines. We also have the longest steel conveyor belt vulcanization machine cold in mining conveyor belt suppliers.

We have mining conveyor belt suppliers able to pass the strict requirements of ISO9001 and ISO14001 as well as ISO45001. Our products have been through quality tests carried out by respected organizations like RWE TUV BV MSHA MASC.

Our RD team comprises experts who are responsible for setting standards for national use We have 32 national utility models patents for example the "multi-ply fabric conveyor belt" and declared 3 invention patents and 11 utility model patents for example like an ultra-wear resistant conveyor belt Our company has formed partnerships with universities to show its leadership position in rubber technology We also have an extensive and efficient after-service team made up of mining conveyor belt suppliers