Mining is a means of digging out valuable elements, specifically minerals like metals and coal. This is significant as it produces many of items that are available to us daily, such as electronics (ex.) cars and even our homes also the places we reside in etc.) That being said, mining can be tough and dangerous work so finding tools to help make it safer as well easier is necessary. Conveyor Belts are an excellent way to help, making the mining process much faster.

A conveyor belt is a long strip of material that wraps around pulleys. It is meant to transport goods from one spot to another with great efficacy. The conveyor belts in the mining industry are utilized for heavy items like rocks, dirt and other materials. The process of mining would be much longer and more difficult without conveyor belts for the workers. Their only alternative would be to lug everything by hand, making the entire process far slower.

Mining is a huge undertaking that requires many machines, equipment and people working together. Conveyor belts are an essential part of making mining faster and more efficient. Instead of having workers carry heavy burdens by themselves, conveyor belts allow materials to pass with little human force. When things are going well, they begin to ease up and get the stress off their own shoulders so that can continue with other important parts of operation-checking equipment, making repairs or ensuring everyone is working safe. The greater ease of work that conveyor belts provide, the more one is able to produce in a given period of time.

Mining can be a dangerous job from the big machinery to sharp rocks, and long hours. In mining, one of the safest ways to keep people safe is by using conveyor belts. Conveyor belts reduce the chance of accidents and injuries by allowing workers to move materials without needing to be close to lethal areas. Strong and reliable conveyor belts are also important as they have to be able to stand up against the extreme conditions found in mining. The benefit of high-quality belts is that they can manage the pressure and provide you a smooth running which is directly proportional to safety.

Conveyor belts are no new idea in the mining sector, they have been used for decades but in that time old technology has broken down and not advanced when compared to what we see today. Certain conveyor belts can accurately shift its gear depending on the materials contained in it. This allows them to operate faster and use less time in computing during the mining process. These and other more advanced forms of conveyors can even help you to catch a problem before it become out of control. This, in turn allows it to notify service crews early on problems that detail needing attention hence preventing break downs and keeping production running.

While mining is a necessary part of the industry but it also has negative environmental impact. Ship All of It Thankfully, innovators have developed new conveyor belt technology that is meant to help reduce the environmental impact from mining. Different examples would be conveyor belts from recycled materials etc. This would help decrease waste and pollution, making mining more environmentally-friendly. Furthermore, a range of new technologies is being developed to reduce water and energy use in mining. More Information By using the next generation conveyor belts, safety can be increased in mines while taking care of the environment.

PVG conveyer belts have the biggest market share in China. The company is backed by the most advanced production equipment, as well as an experienced management team. We are vice-chairman in China's conveyor belt field and also one of the leading makers. The company has been awarded the title of " mining conveyor belt" as well as "The most popular brand in the field of conveyor belts in China", etc.

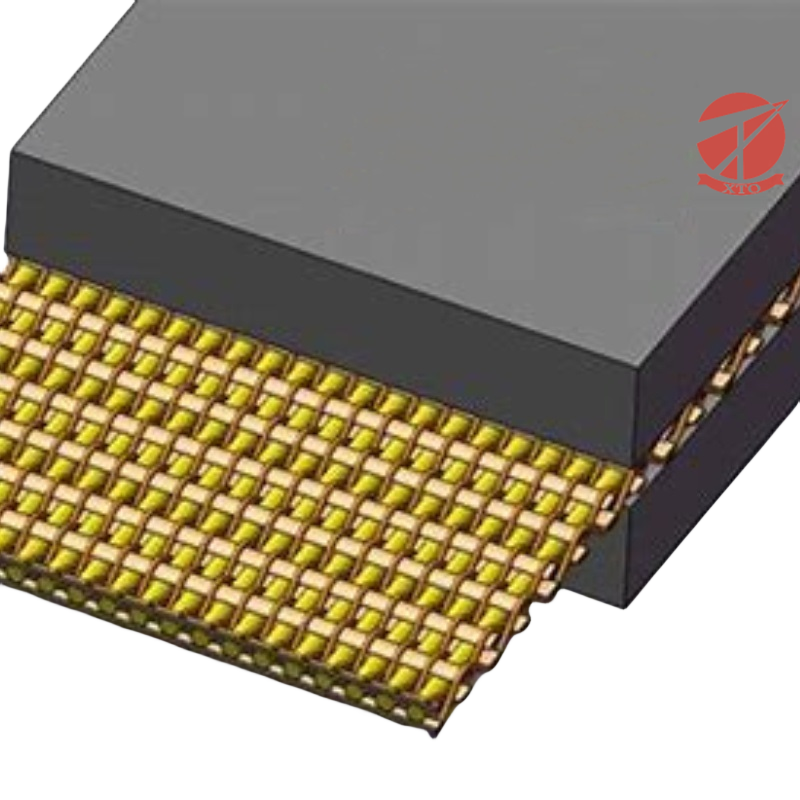

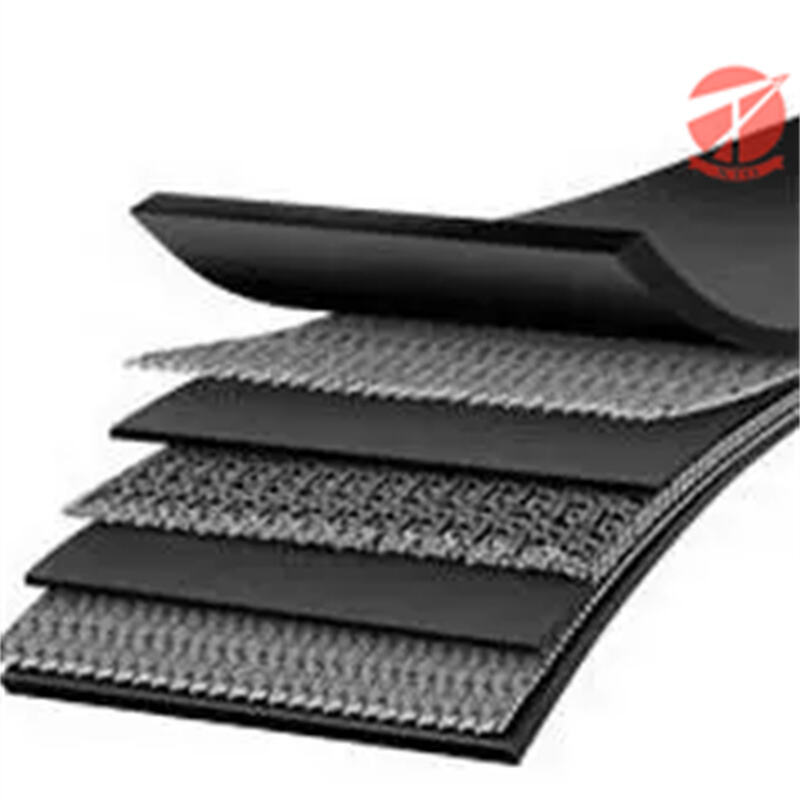

The mining conveyor belt range covers steel cord conveyor belt as well as multi-ply fabric belts. the solid conveyor belt as well as sidewall belt, pipe belt, patterned belt, lifting belt, and an aramid conveyor belt. The annual design capacity of 29 million square meters of conveyor belts. Among them, we have 11 solid woven conveyor belt production lines, 4 multi-ply textile belt producing lines, and 7 conveyor belts made of steel lines. It also has the longest steel cold conveyor belt vulcanization equipment in Asia.

Our RD team includes mining conveyor belt accountable for setting national standards. We have 32 patents for national utility models including the "multi-ply fabric conveyor belt", and declared three invention patents and 11 utility model Patents including an ultra-wear-resistant conveyor belt. Our company has joined forces with several universities to highlight its leading position in rubber technology. Additionally, we have an huge and efficient after-service staff consisting of 32 people.

We have mining conveyor belt able to pass the strict requirements of ISO9001 and ISO14001 as well as ISO45001. Our products have been through quality tests carried out by respected organizations like RWE TUV BV MSHA MASC.