Mining is critical because it allows access to valuable minerals from the Earth. These are used in everything from buildings to cars, computers - etc all things we see or utilize a daily basis! Everything from the car you drive every day to this bucket needed some mining to be possible. Mining by its very nature is pretty inhospitable, and requires some special equipment with which However to Frontier efficient run: conveyor belts

Q-Whats Conveyor BeltA: A conveyor belt is an large, durable strap that bears a load and moves it over the proper location. They have long been applied to carry coal, iron ore or rock over lengthy distances. Consider it like a gigantic, moving sidewalk designed to help you move deadlifts without using your hands. One of The Chief Use of a Conveyor Belt in Mining Industry You are reading : must-visit tourist destination & Best Things to do 2018 Yet things like overburden mining (relocating getting rid from components or minerals etc.), paints, core drills and so on possess crucial significance inside the excavation as well as development stages.

Conveyor belts have an added boost from new technology, according to Smallbiztechnology. A few of the modern-day conveyor belts are composed from a flexible product that tightens up to match the stress on it as well as others just home in promptly. They are also very sturdy, so they do not fall apart easily. Beyond this, the latest belts are so advanced they can even self-diagnose to tell whether a fault is occurring in real-time. This gives an open way for business mining companies from the belts to work faster and more economical.

In mining, part of transporting raw materials is also essential. Probabilities high of spoiling or wasting a lot of other supplies in transportation These materials to lift, and place correctly by any machine is possible but it take so much time upto some length of the top conveyor belts looks easy for that connecting parallel trips from many material. The suspension receives special sensors and control systems to ensure everything rolls smoothly. Conveyor belts never back off then recuperate themselves, Processing the maximum measure of fruit and vegetables with insignificant manual effort gives huge expense saving money on generation yet in addition makes work more secure.

Mining is typically much too high stakes of a game to move as subglacially slow. Conveyor Belts helps in fast and speedy movement of materials, this is the prime reason why every mining company prefers to use a conveyor belt system so that they can extract resources efficiently. This is a robust conveyor belt that should be worn during heavy operation such as large loads, severe usage etc. If a belt wears out, work can also be decreased or halted entirely resulting in delays. To eliminate this, maintenance and repair of conveyor belts is completed so no sudden issues disturb the entire system;

In the mining industry, safety is paramount on mine sites. The design of the conveyor belt should be such that it complies with safety to human and material conveyance. This is why they need to have safety precautions in place for everyone. But they must be green as well, because mining can at times harm nature. Others are with guards designed to keep workers from being caught and emergency stops that shut the whole system down in moments if needed. Rubber conveyor belt are also often made of recyclable material so now less is going to be broken down into the enviroment.

Finally, conveyor belts are incredibly important across the mining sector They help with transporting supplies, make work extra environment friendly and safety. Mining operations also benefit from new technology in the form of conveyor belts and further upgrades to this mechanism. Conveyor belts must be resistant to high strength and secure in the mining sector, therefore proper selection is vital. Regular maintenance keeps all this working as intended

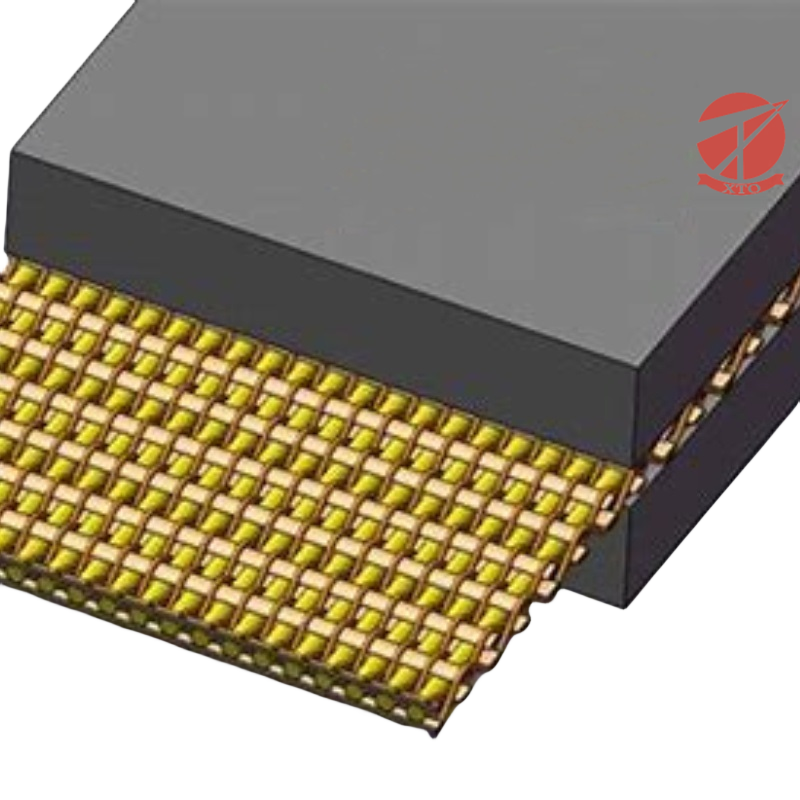

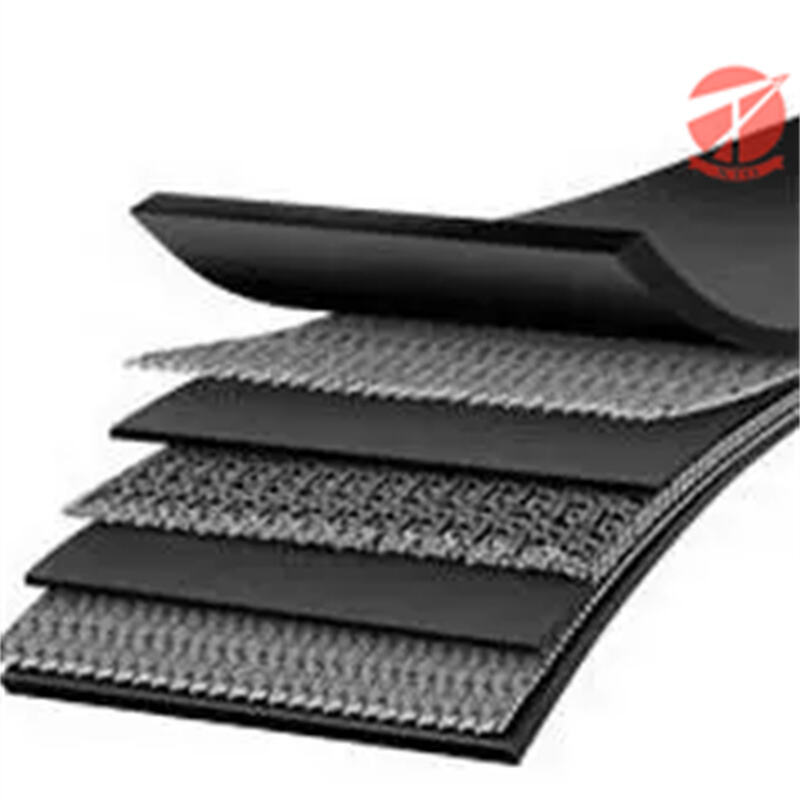

The product line includes conveyor belts made of steel, multi-ply textile belt, solid woven conveyor belt and sidewall belts, pipe belts, patterned belt, lifting belt and aramid conveyor belt. The annual design capacity of 29 million square meters of conveyor belts. Among the belts: We have 11 conveyor belts that are solid woven production lines, four multi-ply textile belt production lines, and seven conveyor belts produced by steel lines. We also have the longest steel conveyor belt vulcanization machine cold in mine conveyor belt.

PVG conveyer belts are the biggest market share in China. The company has the latest production equipment as well as a skilled management team. We are vice-chairman of mine conveyor belt and is one of its leading makers. Our company has received awards such as "China Quality Brand" and "The Most Popular Brand in the Industry of Conveyor Belts in China", etc.

We have a highly skilled RD team with experts who are setting national standards. And we have obtained 32 national utility model patents like "multi-ply conveyor belt made of mine conveyor belt" and has issued a total of 3 invention patents as well as 11 utility model patents such as ultra-wear resistant conveyor belt, and has partnered with a number of universities, which shows the company's leading position in rubber industry technology. We also have an extensive and efficient after-service team made up of 32 individuals.

ISO9001, ISO14001 and ISO45001 are the three rigorous standards that we have successfully mine conveyor belt. And our products have repeatedly been tested for quality by renowned organizations like RWE, TUV, BV, MSHA and MASC.