Conveyor belts are the must-have tools typically brought to work by all productive father in a factory or warehouse, which help them conveniently deliver their goods of labor unabashed. Imagine them as giant moving conveyors made to bring boxes and containers easily along their track. But since conveyor belts have their danger, it is a very important thing you offer prime safety before one even buy material handling belt.

Conveyor belt safety Conveyor belts are an essential part of every construction business, security mainly because they contribute to keeping things in your order. Which means if they get into an accident, the ramifications may be significant. People can be caught in the machinery or hit by objects coming down with everything else on the belt. This also underscores how important it is follow safety protocols and guidelines while working around conveyor belts.

People who work in industrial environments like the one below, with conveyor belts and what have you must always adhere to suggested safety laws concerning tires. All employees must undergo thorough safety training to adequately use a conveyor belt. Moreover, there are specific safety rules that should be followed by employees to have a safe working place near conveyor belts.

Workers are executing staff members corrects and managing in the meantime that they work with conveyor belts. Keep some gloves and safety glasses on hand to prevent injuries. Second, it is important for employees to pay attention to the processes on a belt line and that they do not get too close or interact with them moving parts.

Simultaneously, conveyor belt safety in the workplace is a concern that falls on managers and supervisors. That means continued etraining for employees and strict adherence to safety protocols. It is also important to inspect equipment regularly to ensure that the machinery are in working condition.

This is why there are certain safety regulations that workers need to follow when handling conveyor belts. As an example, this is why people should never put their hands into any moving component of a conveyor belt or come in contact with it at all. For this reason, it is forbidden to walk on a conveyor belt while operating.

Also, labourers only should understand about unexpected topics along with emergency situation procedures in the event that. In the event of entrapment, a swift deactivation method for stopping the conveyor belt to avoid further injury must also be accessible.

How training and technology can boost safety levels

Modernized training practices and technological resources both contribute significantly to improved safety measures for conveyor belts in the workplace. Comprehensive training of employees in safe working practices on the conveyor belts and full support to be provided by companies for timely maintenance & upgradations.

Sensors that stop the operation of a conveyor belt when they detect an obstacle are also important to prevent accidents and occupational diseases, representing technological innovations.

Thus, at the end of all this conveyor belt safety is still to be treaded on by ones inside industrial environment. The result is that companies are going to need long training programs for safe use of the equipment or other very substantial investment on their employee safety part. Working in a safe environment can be made possible if we follow all the safety guidelines and use proper protection gears which would result to minimize accidents and injuries that takes place.

The company boasts modern production equipment, professional management team, and top technology, so that the company has developed into a formidable competitive ability of the enterprise and the PVG conveyer belt holds the highest percentage of the conveyor belt safety in China. We are vice-chairman in China's conveyor belt market and also one of the leading makers. The company was awarded the honor of "China Quality brand" and "The most important brand in the area of conveyor belt in China", etc.

We have a skilled RD team with experts who are creating national standards. We have 32 patents for national utility models including the "multi-ply fabric conveyor belt", and declared conveyor belt safety and 11 utility model Patents, such as an ultra-wear resistant conveyor belt. Our company has worked with various universities to show its leadership position in rubber technology. We also have an extensive and highly skilled after-service department made up of 32 people.

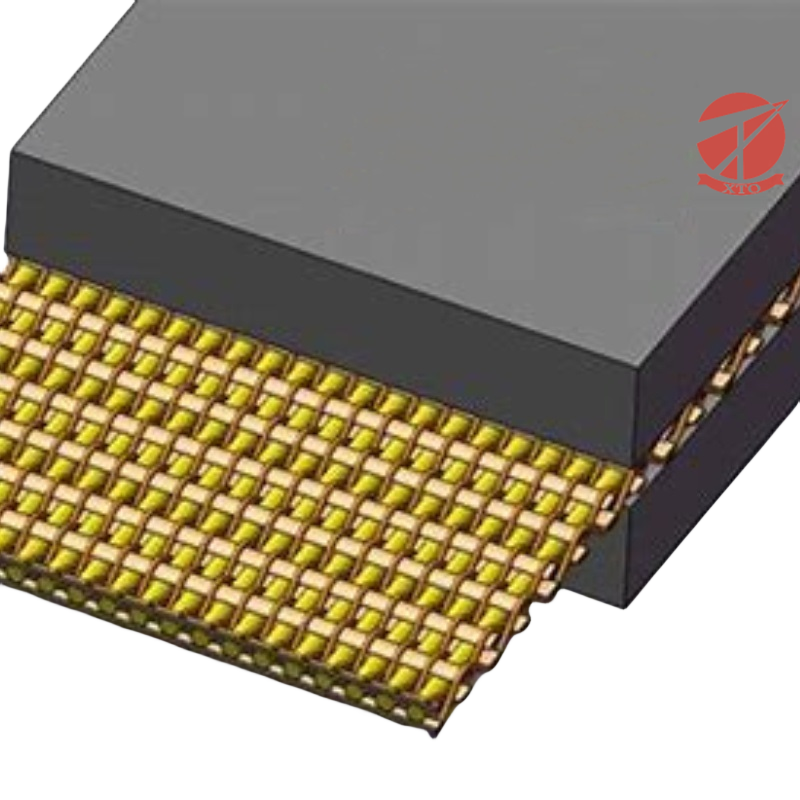

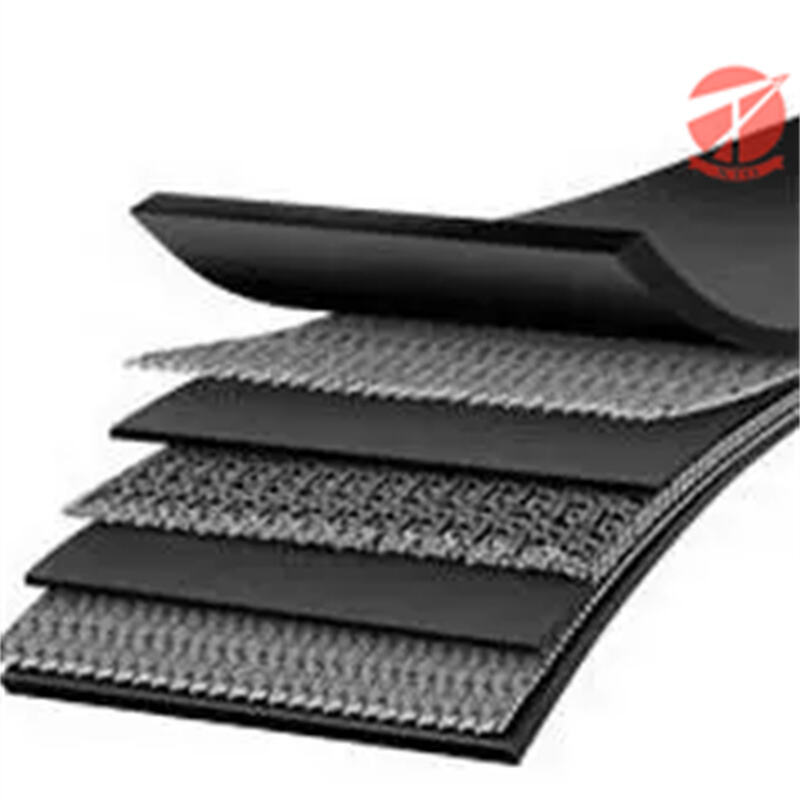

The conveyor belt safety range covers steel cord conveyor belt as well as multi-ply fabric belts. the solid conveyor belt as well as sidewall belt, pipe belt, patterned belt, lifting belt, and an aramid conveyor belt. The annual design capacity of 29 million square meters of conveyor belts. Among them, we have 11 solid woven conveyor belt production lines, 4 multi-ply textile belt producing lines, and 7 conveyor belts made of steel lines. It also has the longest steel cold conveyor belt vulcanization equipment in Asia.

ISO9001, ISO14001 and ISO45001 are the three rigorous standards that we have successfully conveyor belt safety. And our products have repeatedly been tested for quality by renowned organizations like RWE, TUV, BV, MSHA and MASC.