There is a wide range of tools and machinery used in underground mining to guide workmen down deeper into the earth's crust, enabling workers to get closer access with precious minerals. The conveyor belt is one such tool which holds a paramount importance.

A conveyor belt is long in comparison of width and it can take energy to move as the material that we know from daily use, here Electrical power also used. In the case of mining, these conveyor belts are essential in conveying mined ore from the naked depths beneath our feet to a comfortable surface up top.

Mining: A harsh and dangerous profession Old-time mining was, as we all know; a back breaking occupation where the miners had to carry their ore lode by hand up from deep mines. The conveyor belt this is where the importance of a good quality mine transportation system comes to play, and they help in making sure that ease can be prioritised over everything else when it is needed how an ore should normally move from underground mining site into the surface.) [1]

While using conveyor belts underground can provide numerous benefits, They may not only improve productivity in the mines by minimizing and saving time spend tattooing, but aids them get towards broadly increased outputs. In addition, these conveyor belts offer a more secure plus safer way of ore transportation over other transport methods like pulley hoists so as to reduce the risk related deficiencies at work place.

A conveyor belt technology that continues to advance, improve and evolve

Conveyor belts have evolved over the years to meet individual needs of mining operations. Today, conveyor belts come in an extensive variety of forms to accommodate various use cases and make available unique features and attributes. For relatives continuous operation temperatures belt can be selected, or relative realizable transport capabilities of distant enough.conveyors_queues.

Despite this, innovation continues to play an important role in the progressive growth of conveyor belt technology. In underground mining, competent engineers are always looking to develop new materials and technologies which will improve the efficiency of how well conveyor belts perform. That is why the conveyor belt evolution, whether through sensors and automation or advanced materials and coatings, continues to play a significant role in shaping today's mining industry into safer discoveries as well as developing more efficient practices.

In summary, conveyor belts are an integral feature of the mining complex in which they help to safely and efficiently move ore from underground or open pit locations to primary crushers or processing plants. In this way, these conveyor belts guarantee both the competitiveness of mining operations and its safety while reducing risks for accidents & injuries to a noteworthy extent as well escalation in productivity. The future will bring even more innovations of conveyor belts in underground mining as well, with the continuous development of technology.

conveyor belt in underground mining, ISO14001 and ISO45001 are the three strict standards we have successfully completed. Our products have also repeatedly passed the quality testing conducted by renowned companies like RWE, TUV, BV, MSHA and MASC.

The company has advanced production equipment, a professional management team, and first-class technology to ensure that the firm has become a renowned competitive enterprise The PVG conveyor belt is the conveyor belt in underground mining of the market in China. We are vice chairman of China's conveyor-belt field, and is one of its leading makers. The company has been awarded awards such as "China Quality Brand" and "The Most Influential Brand in the Field of Conveyor Belts in China" and many more.

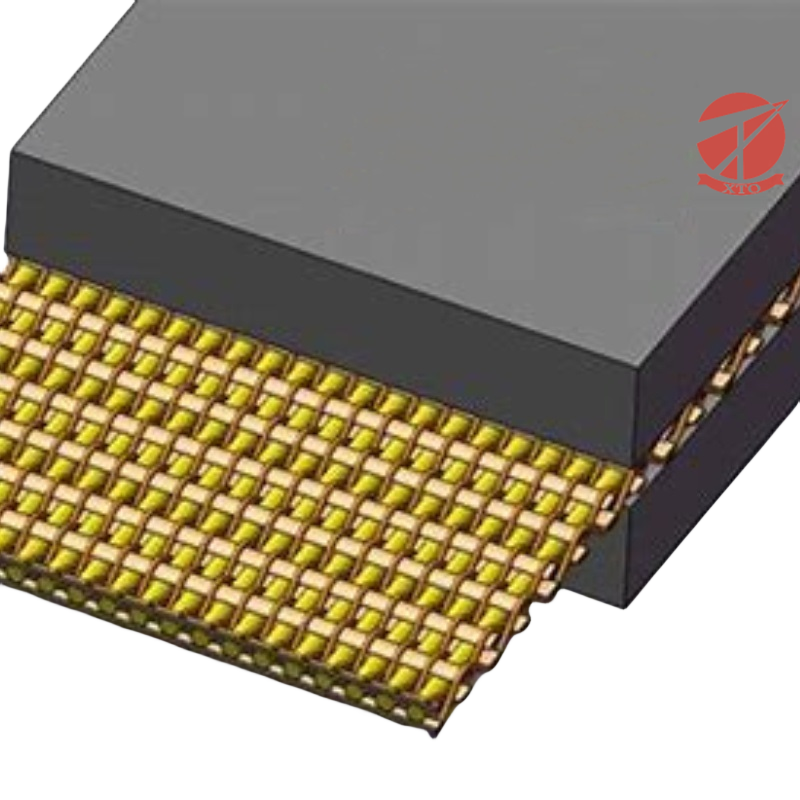

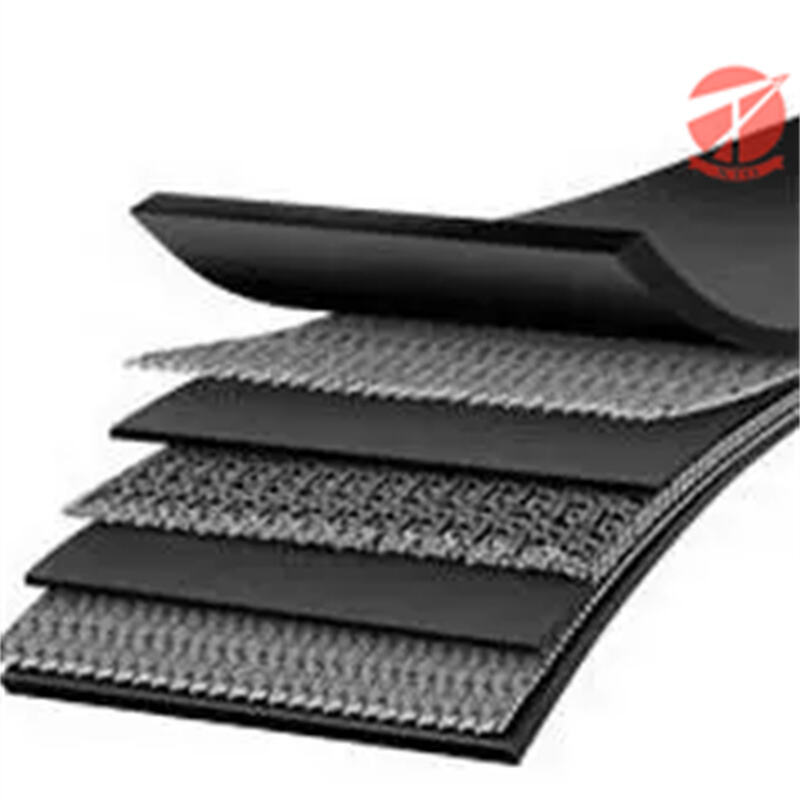

Our conveyor belt in underground mining of products includes steel cord conveyor, multi-ply fabric belts, solid braided belts, pipe with sidewalls, patterned lifting and aramid belts. We have 11 lines of solid woven belts, four lines for multi-ply fabric, as well as seven lines for belts made of steel. It also has the longest steel conveyor belt vulcanization machine cold in Asia.

Our conveyor belt in underground mining team is comprised of experts responsible for setting national standards. And we have obtained 32 utility model patents for national use for example "multi-ply textile conveyor belt" and has issued 3 invention patents, and 11 utility model patents such as ultra-wear-resistant conveyor belts and has partnered with a variety of universities, which shows the company's leading position in rubber industry technology. We also have an huge and efficient after-service staff consisting of 32 people.