- Introduction

Introduction

Usage

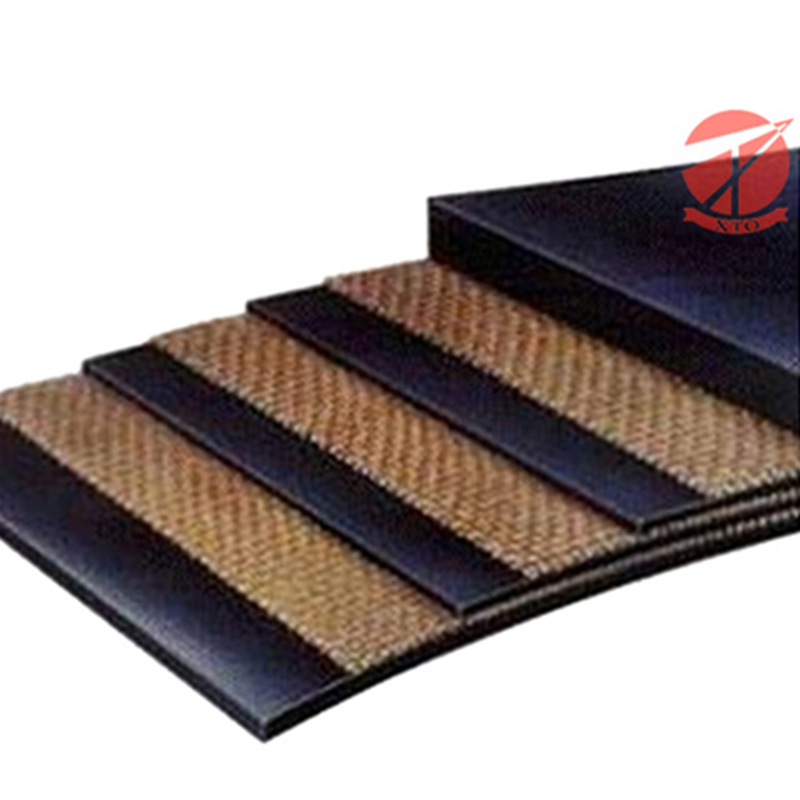

Acid-alkaline resistant steel cord conveyor belts are suitable for conveying materials with chemical corrosiveness in chemical factories, chemical fertilizer factories, paper mills, mining industries, etc.

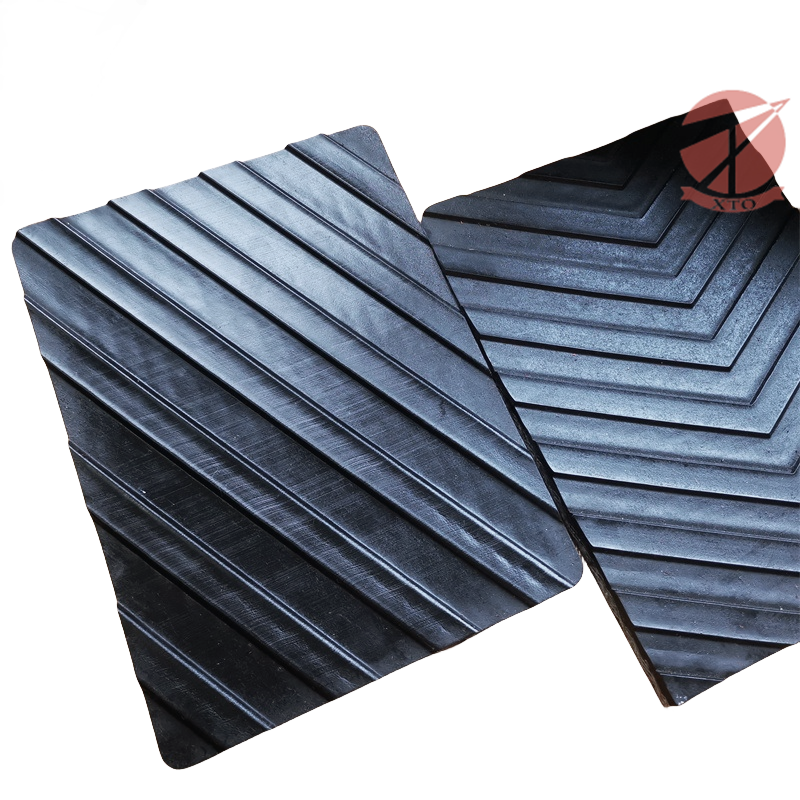

Characteristics

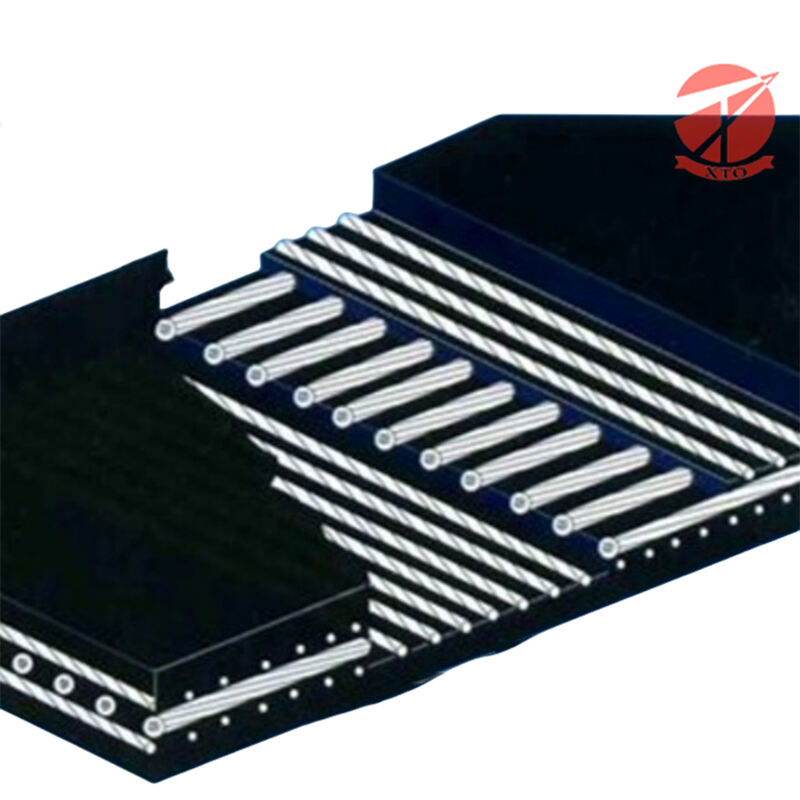

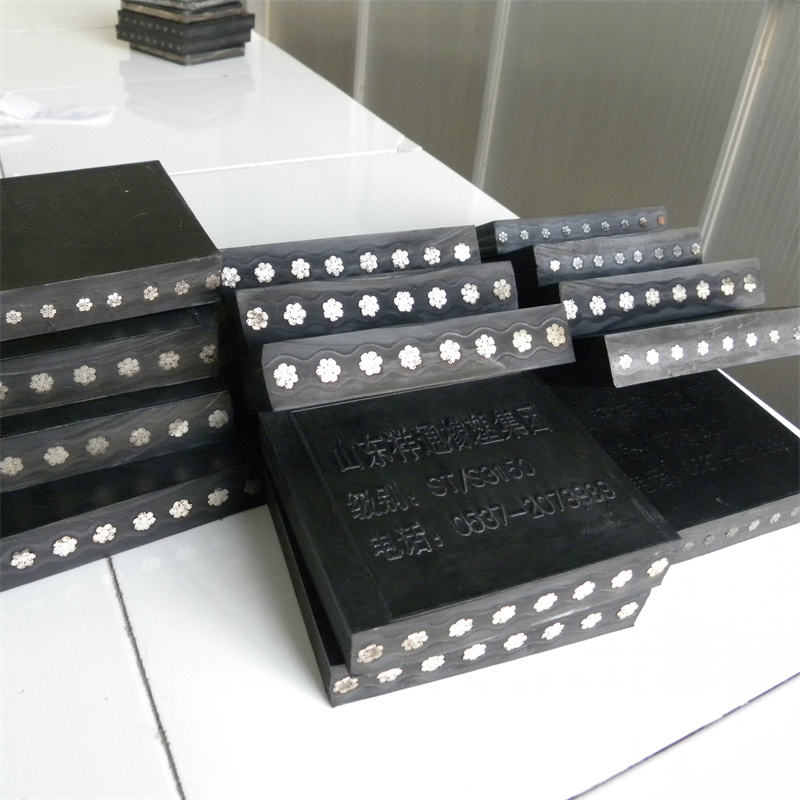

Selecting steel cord as the carcass, the belt has good elasticity and excellent troughability. The rubber cover, which is made from acid- alkaline resistant materials, has great anti-chemical corrosiveness and good physical properties.

Standard Specifications

| Model | Tensile Strength(N/mm) | Cord Pitch (mm) | Cord Diameter (mm) | Min Cover thickness (mm) | Width (mm) |

| ST630 | 630 | 10 | 3 | 4 | 800-2400 |

| ST800 | 800 | 10 | 3.5 | 4 | |

| ST1000 | 1000 | 12 | 4 | 4 | |

| ST1250 | 1250 | 12 | 4.5 | 4 | |

| ST1600 | 1600 | 12 | 5 | 4 | |

| ST2000 | 2000 | 12 | 6 | 4 | |

| ST2500 | 2500 | 15 | 7.2 | 5 | |

| ST3150 | 3150 | 15 | 8.1 | 5.5 | |

| ST3500 | 3500 | 15 | 8.6 | 6 | |

| ST4000 | 4000 | 15 | 8.9 | 6.5 | |

| ST4500 | 4500 | 16 | 9.7 | 7 | |

| ST5000 | 5000 | 17 | 10.9 | 7.5 | |

| ST5400 | 5400 | 17 | 11.3 | 8 | |

| ST6300 | 6300 | 19.5 | 12.8 | 10 | |

| ST7000 | 7000 | 19.5 | 13.5 | 10 | |

| ST7500 | 7500 | 21 | 15 | 10 |

Note: Cover thickness, cord diameter, and cord pitch can be manufactured according to customer’s requirements.

Cover Properties

| Items | Tensile strength Mpa | Elongation and break % | Abrasion mm³ | Hardness A⁰ | Ozone deterioration | ||

| Physical properties | ≥14.0 | ≥400 | ≥250 | 55-70 | No cracks | ||

| Cover | Acid and Alkali resistance | Class | Soak liquid | Density | Soak conditions ℃×h | Change rate before and after soaking | |

| Swelling rate | Change rate of tensile strength | ||||||

| A1 | HCL | 18% | 50℃×96h | <+10% | <-10% | ||

| A2 | H2SO4 | 50% | 50℃×96h | <+10% | <-10% | ||

| A3 | NaOH | 48% | 50℃×96h | <+10% | <-10% | ||